- The study on the effect of calcium chloride deicing agent and concrete compressive strength on scaling

Sung Hyun Eom*, Seong Soo Kim, Jeong Bae Lee and Seung Ho Park

Department of Civil Engineering, Daejin University, 1007 Hoguk-ro, Pocheon-si, 11159 Gyeonggi-Do, Republic of Korea

This experimental study

investigated the durability degradation of concrete exposed to freezing and

thawing and chloride intrusion. In order to observe the degree of the

degradation, 24 MPa, 35 MPa and 60 MPa concretes were used with 4% and 12%

calcium chloride solution as freezing water for scaling resistance and freeze -

thaw resistance tests. The results show that 24 MPa and 35 MPa concrete had a

relatively large decrease in durability due to the freeze-thaw resistance and

scaling resistance, but the 60 MPa concrete was not deteriorated significantly.

In addition, when the concentration of the solution of calcium chloride was 4%,

the degradation of durability was most remarkable. The results of this study

suggest when concrete structures such as bridges or roads expose to the

environmental conditions, appropriate measures such as increasing the designed

standard strength of concrete need to be deliberated and additional studies

should be conducted.

Keywords: chloride-based deicing agent, freezing and thawing, complex durability

In recent years, abnormal weather phenomena have been

occurring all over the world. The increase in precipitation in winter has

resulted in the heavy use of deicing salt in South Korea. During winter, a lot

of deicing agent are sprayed on the roads in order to prevent traffic

congestion and safety accidents when the snow

falls, or the temperature drops under 0 °C. However, it is known that a

large amount of deicing agent on concrete roads causes scaling and peeling on

road pavement surface like concrete near ocean, even though they are inland. In

addition, the use of chloride-containing deicing agent deteriorates the

degradation of performance with the repeated freeze-thaw cycles in winter. In practice, roads and structures

using a general performance concrete are constructed without

considering the complex effects of the use of the deicing salt with freeze-thaw

cycles. Thus, damage to concrete deteriorates the

concrete durability reducing its economic advantages due

to the shortened service life. In addition, the damage of

the concrete pavement causes traffic accidents resulting

in fatalities.

In order to prevent deterioration of concrete structures

caused by chloride-based deicing agent, studies have been conducted on

low-concentration chloride-based deicing agent and eco-friendly

deicing agent, suggesting measures to reduce the deterioration

of concrete [2].

As concrete structures are exposed to more diverse environment,

the performance standards for concrete have been stipulated by various

organizations so as to ensure a certain level of performance. In the case of

Expressway Construction Guide Specification of South Korea [3], various

specified concrete strengths (21 to 45 MPa) are suggested

according to the type of structure. The standard specification for concrete [4] and concrete structure

design code of South Korea [5], water - binder ratio

is specified as maximum 45% and minimum design reference

specified concrete strength is 30 MPa for concrete exposed to freeze - thaw or

deicing chemical in wet condition.

This study evaluated the durability of concrete subjected

concurrently to chloride-induced corrosion and freezing damage according to the

calcium chloride concentration using a high-strength concrete mixture and

concrete suggested in domestic and international specification regulations.

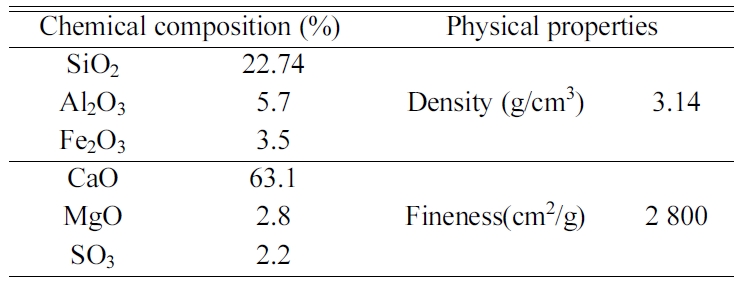

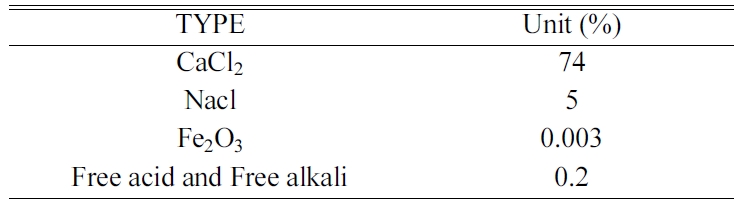

The physical properties and the chemical composition

of the ordinary portland cement are shown in Table 1. The deicing agent uses

the calcium chloride specified in ASTM C 672 [6] and the chemical composition

and properties are shown in Table 2. The aqueous solution of calcium chloride

was prepared at 4 and 12% used in the test.

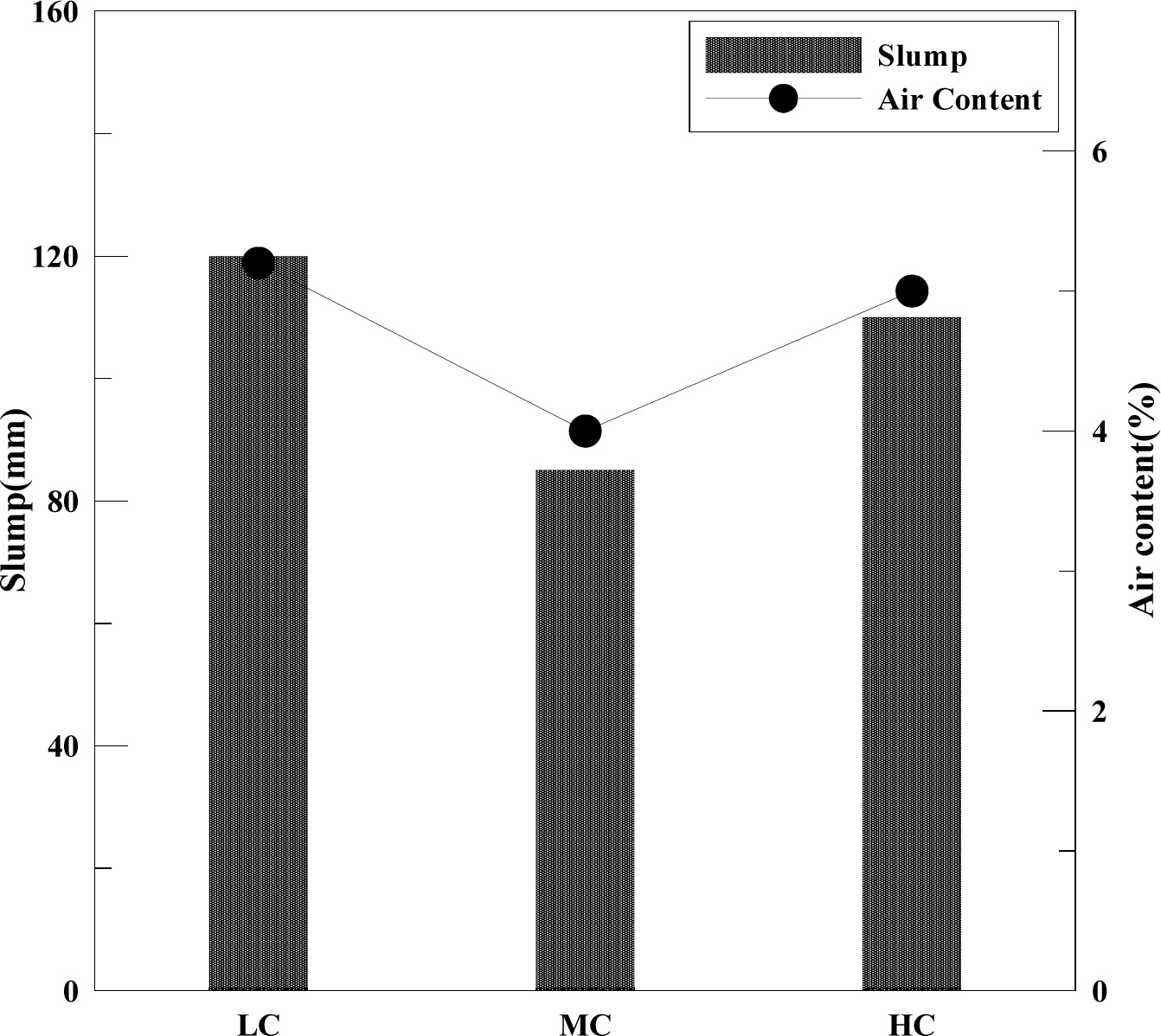

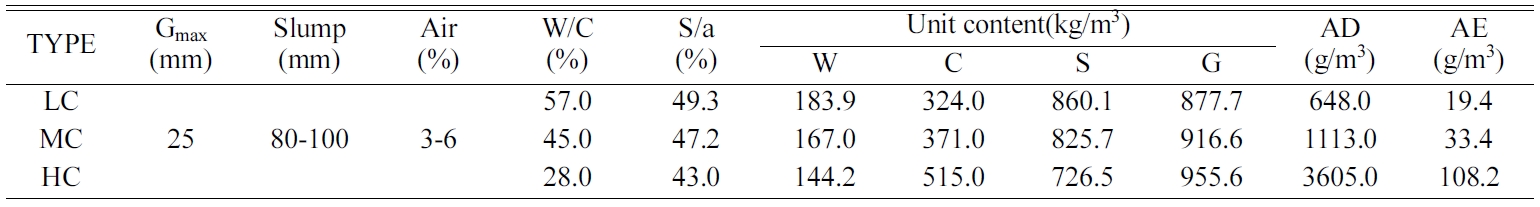

The concrete selected in this

study was designed to be 24 MPa, 35 MPa, 60 MPa. Detailed concrete formulations are

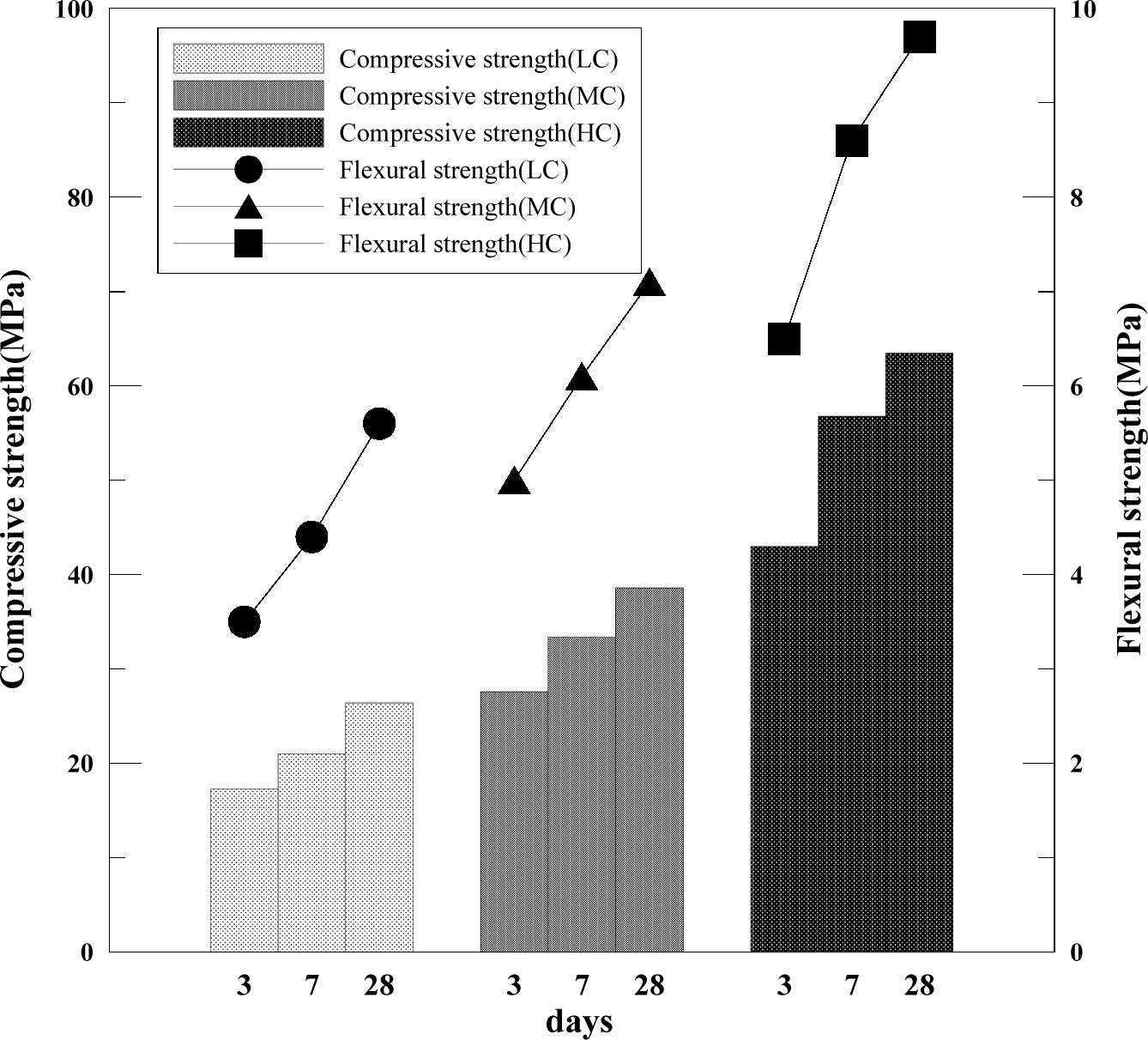

shown in Table 3. The slump and air content are shown in Fig. 1. The slump is 100 ± 20 mm and the air content is 4.5 ± 1.5%. Compressive

strength and tensile strength were measured at 28 days, and the results are

shown in Fig. 2. As shown in Fig. 2, the compressive strength at 28 days is

close to the target compounding strength. Also, the flexural strength was about 17% of the compressive strength. The compressive strength and the flexural strength were measured

according to the method described in ASTM C 192 [7], and the compressive strength was measured

according to ASTM C 39 [8] after curing in water at 20 ± 2 °C for a period of time. The tensile strength was

measured according to ASTM C 1583 [9], and after the completion of the freezing-thaw resistance and scaling resistance test, a 50 × 100

mm core specimen was taken and its compressive

strength was examined. In order to investigate

the freezing and thawing resistance of calcium chloride deicing agent

environment, 4, 12% aqueous solution of calcium chloride was used as frozen

water. The test method was examined by the A TYPE test method of ASTM C 666

[10], and the relative dynamic modulus of elasticity

was measured for every 30 cycles, from -18 oC to -4 oC.

The scaling represented by the deterioration phenomenon of the

concrete surface in the repeated environment of salting, freezing and thawing

was studied. For this study, the amount of scaling was confirmed every 30

cycles using 0, 4 and 12% aqueous solution of calcium chloride as freezing

water according to the test method of ASTM C 672, and the freezing and thawing

repeated temperature was determined by A type test method of ASTM C 666.

Finally, to evaluate the penetration resistance of the

ions, NT Build 492 [11] was used as a test method of accelerated chloride

penetration as the chloride ion diffusion coefficient of concrete at the age of

28 day was compared.

|

Fig. 1 Slump and air content. |

|

Fig. 2 Compressive and flexural strength. |

|

Table 1 Chemical composition and physical properties of ordinary Portland cement. |

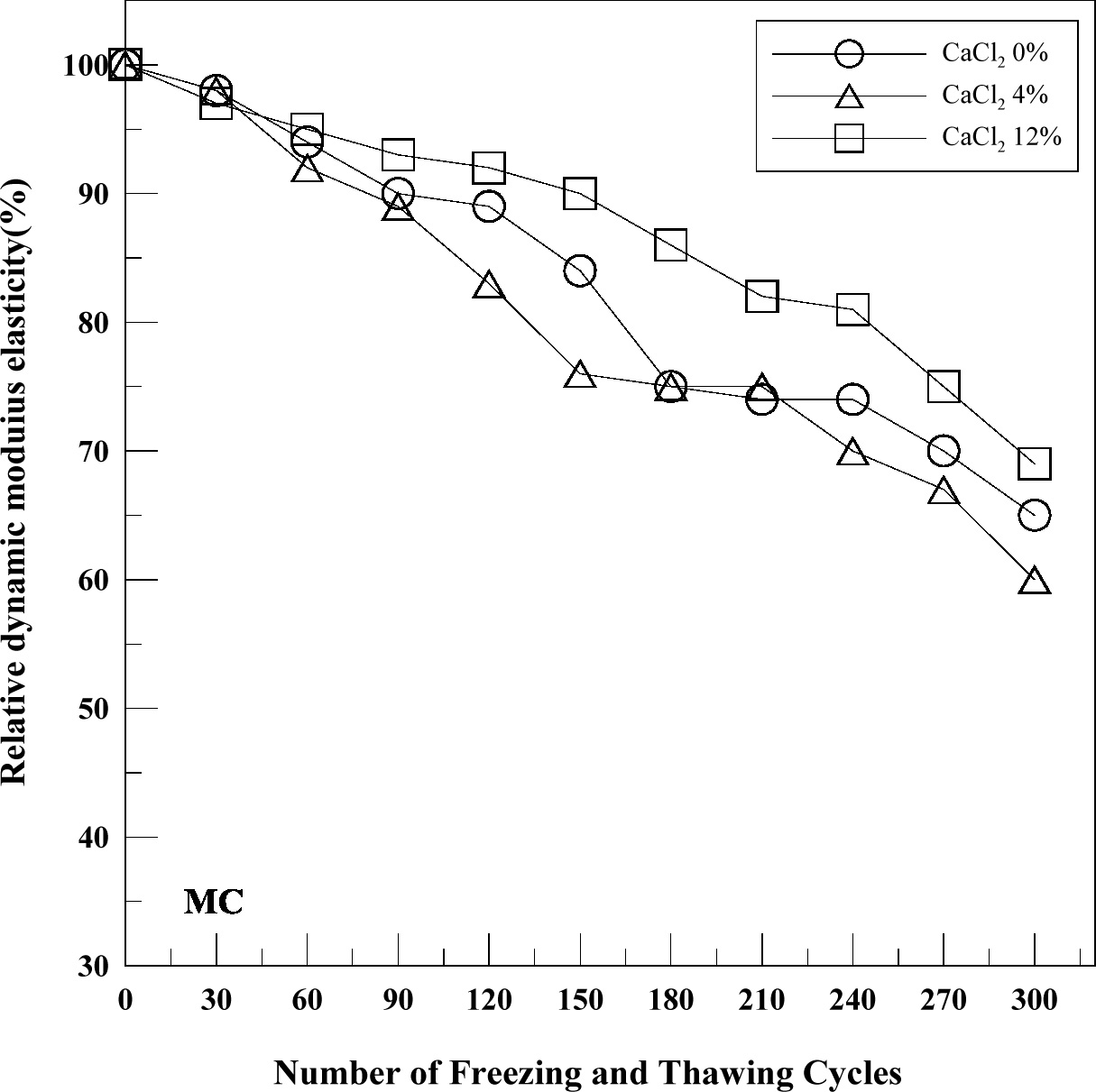

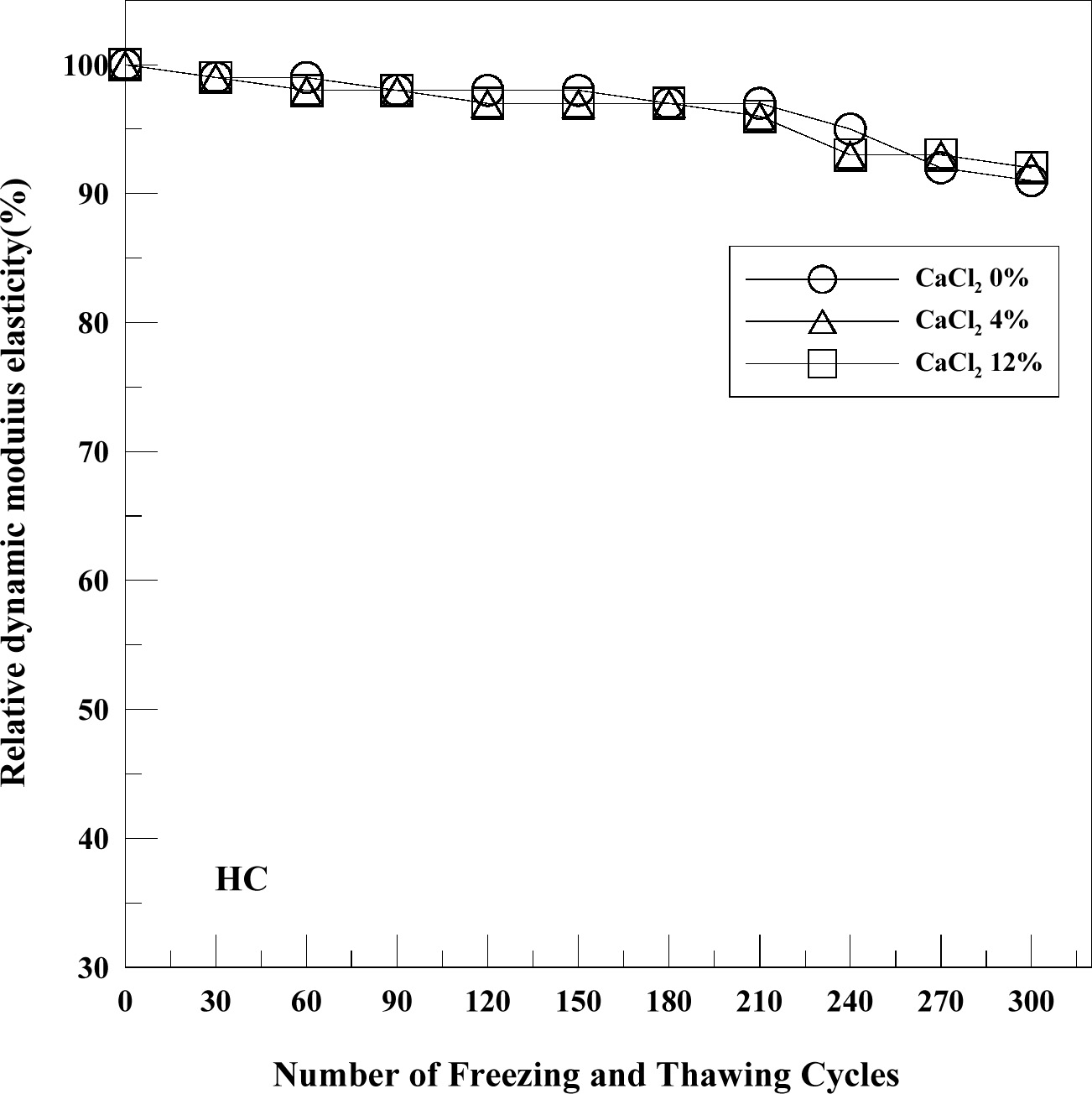

The freezing-thawing resistance is shown in Figs. 3 to 5.

As shown in Fig. 3 to 5, the LC displayed the lowest relative dynamic elastic

modulus ratio. The experiment using an aqueous solution of 4% calcium chloride

concentration to simulate a deicing agent had the lowest

relative dynamic elastic modulus as compared to

experiments that used ordinary water or an aqueous solution with calcium

chloride concentration of 12%.

Relative dynamic modulus elastic ratio is different depending

on the level of compressive strength. In detail, 59% lower

for LC and 40% lower for MC using the aqueous solution with the

calcium chloride concentration of 4%, It was confirmed that the

relative dynamic modulus ratio was decreased to less than 10% in all specimens

for HC, this is confirmed that the performance

deterioration due to freezing and thawing was not relatively large.

As the compressive strength increases, the resistance to

freezing and thawing was relatively high because the amount of internal surplus

water decreased when concrete was frozen because the water-cement ratio of

concrete decreased.

Another reason is that as the compressive strength

increases, the internal structure becomes dense. The pressure due to the

expansion of the freezing water is insignificant. In addition, it was difficult

to penetrate the aqueous solution of calcium chloride due to the closed matrix

of the concrete inside. Therefore, it is considered that the complex

deterioration effect of the freezing and thawing repetition, and salt corrosion

on concrete was not significant.

The experiment using an aqueous solution of 4% calcium

chloride concentration to simulate a deicing agent had the lowest relative

dynamic elastic modulus as compared to experiments that used ordinary water or an

aqueous solution with calcium chloride concentration of 12%. The

cause of such results may be because the 4% calcium

chloride concentration has a higher freezing temperature

than its 12% counterpart, leading to more active repetition of freezing and

thawing [12]. When freezing water is used as the water without using calcium

chloride, the freezing temperature is higher than that of using the deicing

agent, but the durability of the concrete was not deteriorated as much as

exposed to the deicing salt.

Therefore, when freezing water is used as the water with

using calcium chloride, it is considered that the ratio of relative dynamic

modulus of elastic was drastically reduced as the performance of concrete was

deteriorated by the combined effects of freeze-thawing and deicing salt damage.

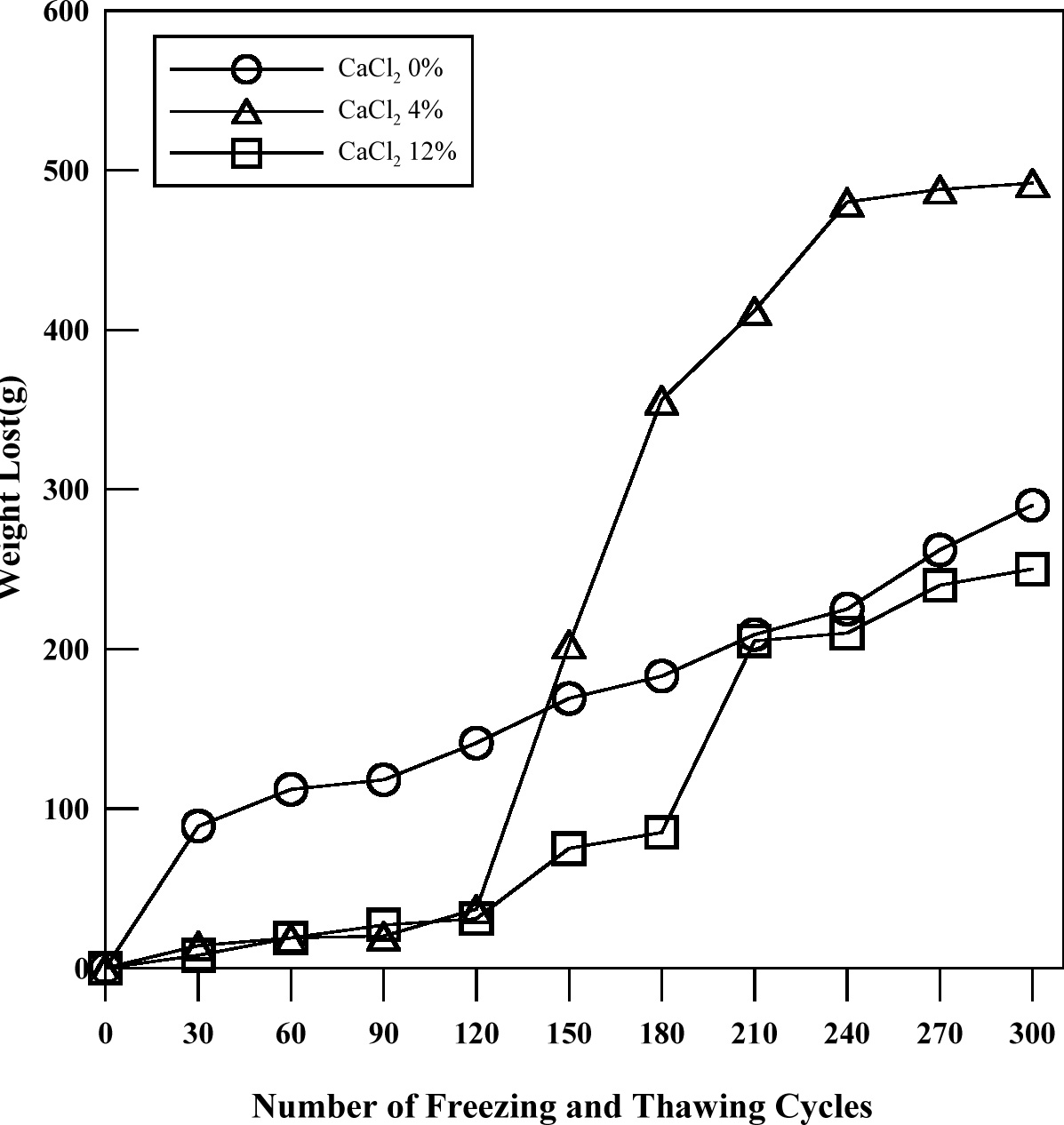

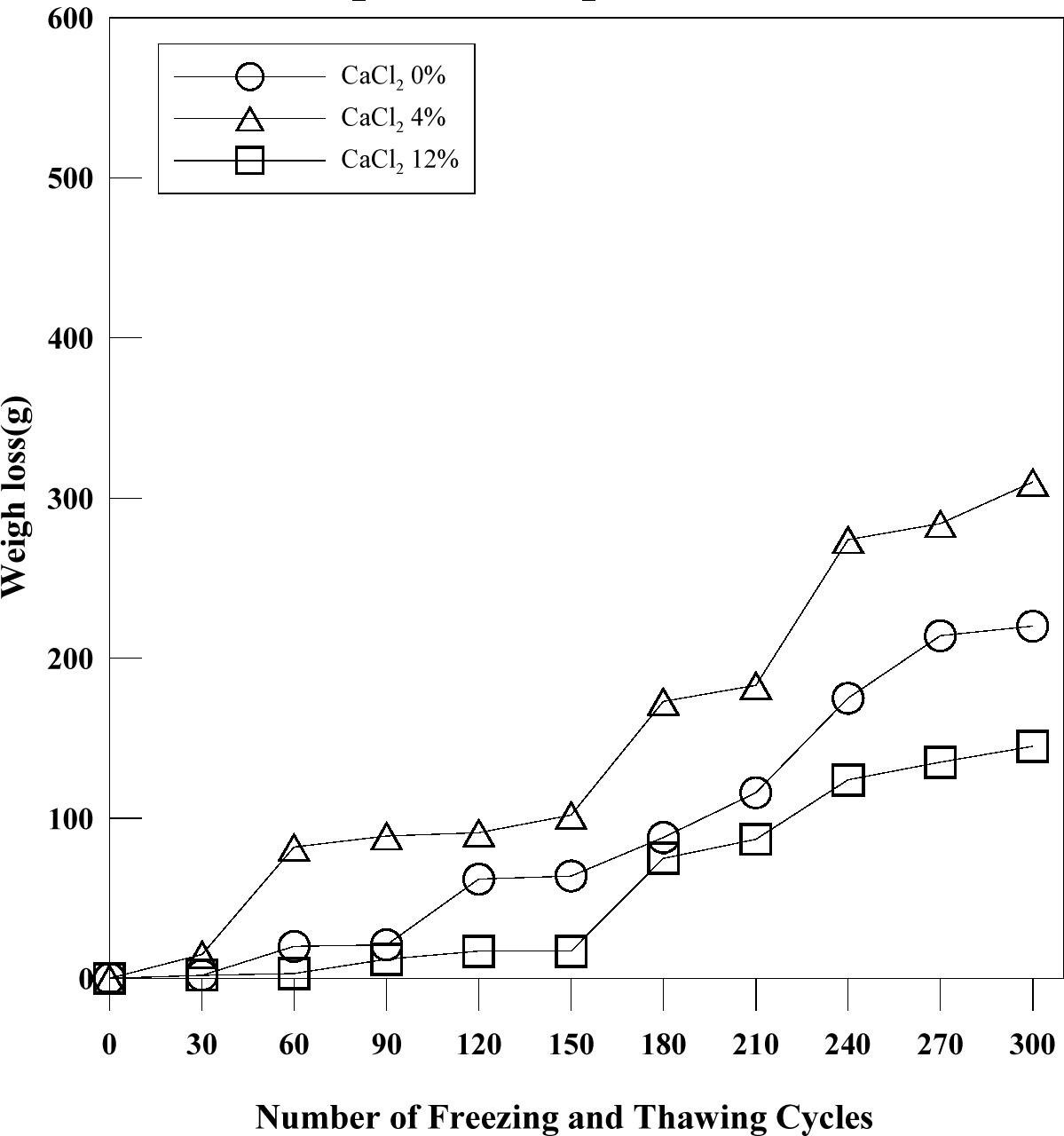

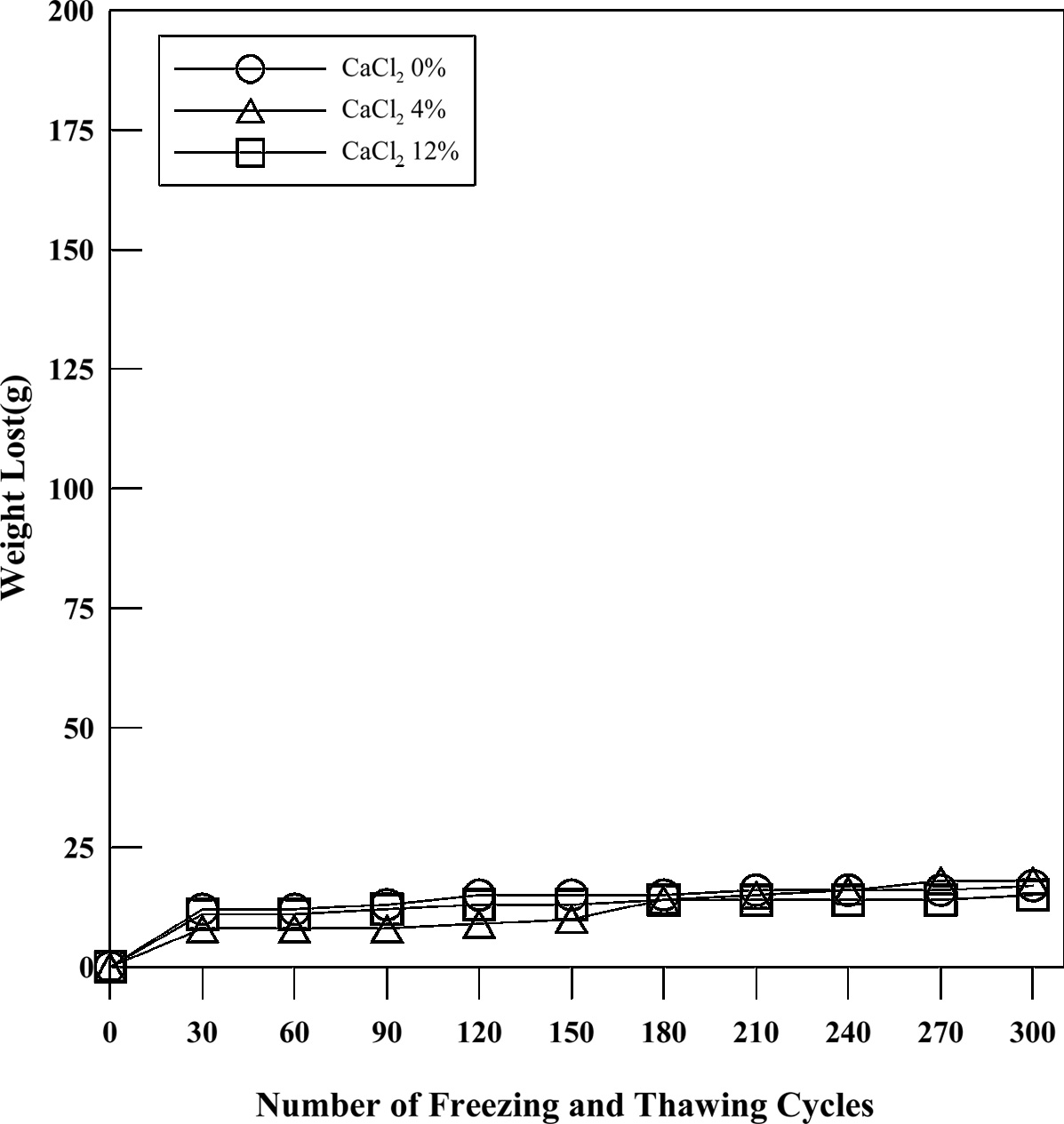

Figs. 6 to 8 show the scaling amount of concrete specimens

measured every 30 cycles of freeze-thaw cycles. As shown in the figures, LC and

MC showed that the most scaling occurred when using an aqueous solution with a

calcium chloride concentration of 4%. It was confirmed that the HC, which is a

high strength concrete, remarkably reduces the amount of scaling compared to LC

and MC. Concrete with low water - cement ratio or high strength showed little

effect on scaling.

As a result of the concentration of aqueous solution of

calcium chloride, the amount of scaling was large in the case of using 4%

aqueous solution of calcium chloride as the freezing water, and the decrease in

strength was greatest at the end of the scaling test 46% for LC, and 13% for the high strength concrete HC. The

reason for this result is that the freezing temperature of 4%

aqueous solution was higher than the freezing water of 12% of calcium chloride

as in the results of the freezing and thawing resistance

tests [13]. As shown in Fig. 6, when the 4% aqueous solution of calcium

chloride was used as the freezing water, rapid scaling was observed between 120

and 150 cycles of freezing and thawing. It is considered that the scaling was accelerated

as the deterioration of the concrete performance was

accelerated by the complex effect of repeated

freeze-thaw cycles and the salt damage. Compared to LC the rapid

deterioration phenomenon was not observed in the case

of MC. However, the scaling tendency was the same as that of LC when the

calcium chloride 4% aqueous solution.

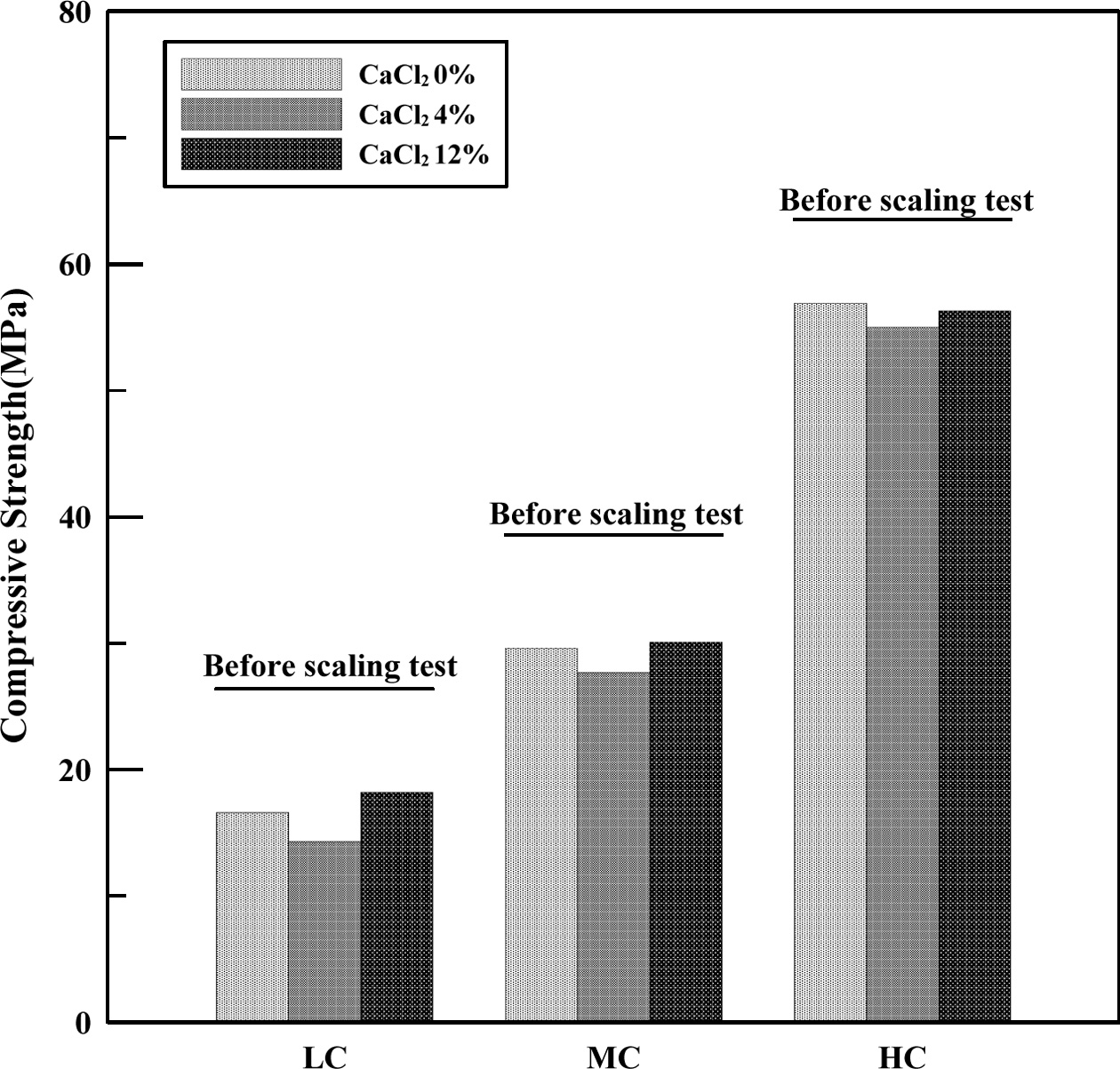

Fig. 9 shows the compressive strengths of all specimens

after accelerated scaling. The average compressive strengths of the specimens

were 38% for LC, 25% for MC and 12% for HC lowered. It demonstrates that when

the deterioration caused by freezing and thawing and scaling continues for a

long time, it would be difficult to secure the stability of the concrete

structure.

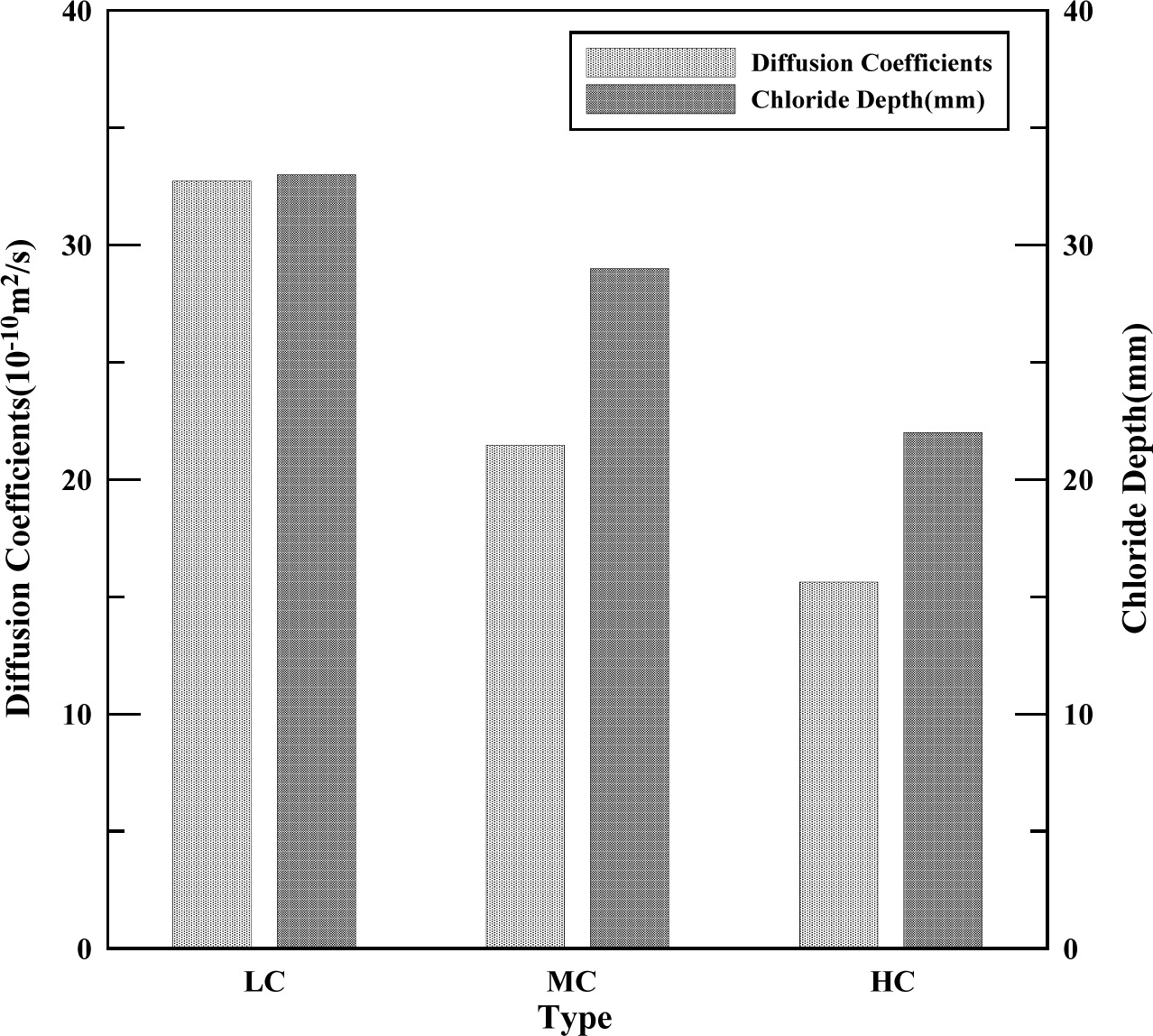

In this study, chloride ion diffusion test was performed

to evaluate chloride penetration resistance and

watertightness of ions and the durability of concrete by comparing

with scaling amount. As shown in Fig. 9, the chloride ion diffusion coefficient

and the scaling amount decreased rapidly with increasing compressive strength,

such as the chloride ion diffusion coefficient of 28 days and the scaling

amount measured after 300 cycles. The results may be due to the water-cement

ratio is high and the compressive strength is low, the concrete are not

densified, and the amount of pores distributed in the microstructure is large,

so that the chloride ions are easily diffused into the concrete, It is judged

that the deterioration due to scaling is increased. Fig. 4 Fig. 7 Fig. 10

|

Fig. 3 Relative dynamic elastic modulus LC. |

|

Fig. 4 Relative dynamic elastic modulus of MC. |

|

Fig. 5 Relative dynamic elastic modulus of HC. |

|

Fig. 6 Scaling of LC. |

|

Fig. 7 Scaling of MC. |

|

Fig. 8 Scaling of HC. |

|

Fig. 9 Compressive strength after scaling 300 cycle. |

|

Fig. 10 Chloride ion diffusion coefficients. |

In this study, to investigate the durability degradation

of concrete in environmental conditions that simultaneously

receives salting and freezing and thawing, compressive strength of concrete was

classified into three types. Concrete performance deterioration by

calcium chloride deicing agent concentration was investigated and

the following conclusions were obtained.

1. In the freezing and thawing

resistance experiment conducted using an aqueous calcium chloride solution as

the deicing solution, performance loss was the greatest when the percentage of

calcium chloride in aqueous solution was 4%. Compressive Strength of 24 and 35

MPa Concrete showed a significant decrease in performance due to the

freeze-thawing and salt-smoothing effects. In the case of high-strength

concrete with a compressive strength of 60 MPa, the concrete strength was increased by maintaining the relative dynamic

modulus of 90%. It was confirmed that this method is effective for ensuring

durability.

2. As a result of the resistance

to scaling, it was confirmed that the scaling amount was the largest when using

4% aqueous solution of calcium chloride as freezing water

in all cases of LC, MC and HC. However, in the case of LC and MC, which are ordinary concrete, the degradation

of performance due to scaling is large and the performance degradation due to

scaling is relatively small in HC as a high-strength concrete.

3. As a result of measuring the

compressive strength of the core specimens collected from the scaling test

after 300 cycles of repeated exposure, the strength was lower when 4% aqueous

solution of calcium chloride was used as the freezing water

compared to water without calcium chloride or aqueous

solution with calcium chloride concentration of 12%. It was confirmed that the

strength was significantly lowered as compared with the case where 4% calcium

chloride solution was used as freezing water.

4. The relationship between

the chloride ion diffusion coefficient and the scaling amount of the concrete

was examined and it was confirmed that the scaling amount was increased with

the concrete having a high chloride ion diffusion coefficient. As the diffusion

coefficient of chlorine ion decreased and the compressive strength increased,

the decrease in the scale amount was larger, and it was judged that the

strength enhancement was effective in securing durability against freezing and

thawing and salting.

This work was supported by the Korea Institute of Energy

Technology Evaluation and Planning(KETEP) and the Ministry of Trade, Industry

& Energy(MOTIE) of the Republic of Korea (No. 20131020102300).

- 1. K.-B. Lee and S.-W. Lee, J. Korean Soc. Civ. Eng. 27[1D] (2007) 73-80.

- 2. B.-D. Lee, B.-S. Yun, J.-K. Lee, and Y.-H. Chung, Int. J. Highw. Eng. 7[4] (2005) 113-123.

- 3. Expressway Construction Guide Specification of Korea (Korea Expressway Corporation Press, 2012).

- 4. Standard Specification for Concrete of Korea (Korea Concrete Institute Press, 2009).

- 5. Concrete Structure Design Code of Korea (Korea Concrete Institute Press ,2012).

- 6. ASTM Standard, No. ASTM C 672 (2012).

-

- 7. ASTM Standard, No. ASTM C 192 (2019).

-

- 8. ASTM Standard, No. ASTM C 39 (2018).

-

- 9. ASTM Standard, No. ASTM C 1583 (2013).

-

- 10. ASTM Standard, No. ASTM C 666 (2015).

-

- 11. Nord test, NT BUILD 492 (1999).

- 12. degradation Research Committee report of concrete structures due to snow melting (Japan Concrete Institute Press, 1999).

- 13. Marchand. J, Pigeon. M, Bager. D, and Talbot. C, ACI Mater J. 96[4] (1999) 429-435.

-

This Article

This Article

-

2020; 21(2): 164-169

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.164

- Received on Aug 5, 2019

- Revised on Mar 18, 2020

- Accepted on Mar 27, 2020

Services

Services

- Abstract

introduction

material and methods

results and discussion

summary and conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Sung Hyun Eom

-

Department of Civil Engineering, Daejin University, 1007 Hoguk-ro, Pocheon-si, 11159 Gyeonggi-Do, Republic of Korea

Tel : +82-10-2032-6929 Fax: +82-31-533-9580 - E-mail: esh905e@naver.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.