- Ruthenium(II) dicarboxylated bipyridyl based metal organic polymer as a sensitizer for nanostructured TiO2 based dye-sensitized solar cells (DSSC)

Sathishkumar Chinnasamy and Sivasubramanian Ramanathan*

Electrochemical Energy Materials and Sensors Laboratory, NRIIC, PSG Institute of Advanced Studies, Coimbatore-4, Tamilnadu, India

In this work,

ruthenium(II)bis(2,2'-bipyridyl4,4'-dicarboxylicacid)(pyrazine)bis(tetrafluroborate)

[Ru(II)(dcbpy)2(pyz)]n(BF4)2n]

based metal organic polymer (RuMOP-Pyz-1), was synthesized at room

temperature under inert atmosphere and their performance in dye-sensitized

solar cells (DSSC) were studied. The metal organic polymer was prepared by

coupling pyrazine as linker units with the Ru(II) dicarboxylated based mono

metallic complex. The UV-visible absorption profiles covered a broad range of

absorption and the formation of polymer leads to shift in the absorption

wavelength. The metal mediated π-conjugation units in the polymer complex

exhibit a strong emission at λem = 552 nm with an excitation

wavelength of 395 nm. The synthesized metallo-polymer was employed as a

sensitizer in DSSC and the maximum power conversion efficiency (PCE) value of ɳ

= 1.507 % with short circuit current (Jsc) of 3.22 mA/cm2;

open circuit voltage (Voc) 0.684 V and Fill Factor

(FF) of 68.45 % under Air Mass (AM) 1.5 G simulated sunlight at a light

intensity of 100 mW/cm2 was obtained. The efficiency of the device

and its photovoltaic performances were found to be satisfactory. The enhanced

performance of the device is attributed to the presence of extended conjugation

of the metallo polymer which helps in a facile electron transfer from the HOMO

to LUMO of TiO2.

Keywords: DSSC, metallo-polymer, poly-Ru(II)dicarboxylated bipyridyl, pyrazine, photovoltaic, sensitizer

Dye sensitized solar cells (DSSC) are currently attracting significant

attention as alternative to conventional silicon solar

cells [1, 2] due to their low production cost, simplicity

of fabrication, lightweight, array of colour and high power conversion

efficiency (PCE). DSSC have been intensely pursued in last two decades

and has found many applications such as flexible electronics, transparent

conducting windows, etc. [3-5]. Typically DSSC is a multilayer device, where

nanocrystalline titania coated on a conductive substrate act as a

photoanode, platinized counter

electrode act as a photocathode. The photoanode (TiO2) with

the dye and the photocathode electrode were bridged

by a redox electrolyte, which mediates the charge transfer

between the electrodes. The sensitization is usually a metal based organic dye

which helps to improve the overall efficiency of DSSC [6, 7]. As

being a multilayer device, the most important components of

DSSC is the photosensitizer [8-10] and the efficiency of DSSC mainly depends on

the performance of the sensitizers [11].

In view of the potential application of DSSC, more number

of research works focused on each layer of DSSC like the photoanode, the photo

cathode, the dyes and the electrolyte. In the case of photo anode, various nanostructured ceramics

[12], semiconductor metal oxides with optimized

layer deposition and sintering process [13] were examined. Further,

in the case of photo cathode DSSC performances were enhanced by the addition of

conducting ceramic nanoparticles [14] and microporous ceramics [15] in

electrolyte systems. Specially, to

increase the near-infrared solar cell response by introducing transparent ceramics [16] and to get excellent

pigmenting materials through new ceramic dyes [17] has also been developed.

Predominantly, the ceramics based material for DSSC

research were played a vital role in various approach. Particularly, by

introducing TiO2 nanowires, carbon nanofibers

and porous carbon nanofibers with Pt catalysts were

reported effective results [18-22]. Hence, ruthenium

nanocrystals, composites based on TiO2 nanoparticle/nanowires,

size-selected titanium dioxide nanowires, mixed transition metal oxides TiO2

based photoanodes were also incorporated for efficient dye sensitized solar

cells [23-27]. By introducing various synthetic designs in dye structure and

blended structures of polymers [28] would increase the efficiencies of the

solar cells. So, enhancing the DSSC performance by introducing new functional

dyes is the focus of the current research [29]. Different types of dyes have

been used in DSSC, including natural [30], organic [31, 32] and

organometallic dyes [33] based on various transition elements

[34]. Predominantly, ruthenium complexes have received intensive interest due

to their favorable photo-electro-

chemical properties and high stability. Among these sensitizers

ruthenium polypyridyl based complexes have shown the best photovoltaic

performance due their better light harvesting properties upon absorption [35].

In particular, the dicarboxylated bipyridine based mononuclear

dyes N3 and N719 dye were considered as standard dyes due to their best

photovoltaic performance [36, 37]. So far several DSSCs

based on ruthenium complexes have achieved photovoltaic efficiencies of over

10% under standard measurement conditions and the highest value is about 12%

[38, 39].

Recently, inorganic perovskite sensitized solid state DSSC

have reached an efficiency of 20.1% [40]. On the other hand, the environmental

and health hazards owing to the occurrence of toxic components hold back their

commercial applications [41-43]. So, there is a high demand in the ruthenium

based sensitizers which achieves high efficiency with proper electronic and structural

properties [44]. In the case of standard sensitizers like N3

dye, the main drawback is the ambidentate thiocyanate ligand which will

coordinate either at the nitrogen atom or at the sulfur atom. So as to solve

the problems associated to NCS ligand based dyes, cyclo- metallated ruthenium complexes were

projected in the last three decades [45]. An immense effort has been made to

optimize the molecular structure of ruthenium complex by

varying ancillary ligands, typically bipyridines which can be

tuned by different substituent’s to modify their photochemical and

photophysical properties [46]. It has been well-accepted that

raising the molar extinction coefficient of a sensitizer is a

well-designed approach to enhance the photovoltaic performance [47].

Another important factor that hinders the performance

of DSSC is the poor thermal stability [48]. To overcome

this problem, supramolecular metallo-polymers with extended π-conjugation units

were employed. These metallo-polymers exhibit the combination of both the

properties of organic and organometallic compounds [49]. Moreover, these dyes

show not only competent light harvesting efficiency but also

an extended absorption with high molar absorption

coefficient. Besides an effective intramolecular spatial charge separation of

the excited state are critically important for better

performance. Ruthenium based metallo-polymers which consists more

number of conjugated units has various advantages, such

as long-lived metal to ligand charge transfer (MLCT) and

ligand centered redox process [50]. Employing the organic polymeric materials

as sensitizers in DSSC has been recently recognized and comparatively modest research

work done has been carried out [51]. In this work, we

report the synthesis and characterization of ruthenium (II)bis(2,2'-bipyridyl4,4'-dicarboxylicacid)

(pyrazine) bis(tetrafluroborate) based metal

organic polymer (RuMOP-Pyz-1) and their efficacy as a photosensitizer is

examined.

Materials

and methods

RuCl3.3H2O, 4,4'-dimethyl

2,2'-bipyridine (bpy) (<99%), 10% palladium on charcoal, Pyrazine

(<99.5%), silver tetrafluroborate (AgBF4) (<99%), P25

TiO2 powder (<99%), TiCl4 solution, chloro platinic

acid (H2PtCl6), ethanol, N-methyl pyrrolidine (NMP),

acetyl acetone and diethyl ether were purchased from Sigma Aldrich and were

used as received. Triton X - 100 (<98%) were purchased from Merck and used

as received. All the synthetic reactions were performed

under inert condition. The solvents employed for the

synthesis were reagent grade which were freshly distilled and degassed prior to

use.

Characterization

The absorption spectra were recorded in DMF by using

Shimadzu UV-1800 UV-VIS spectrophotometer (Japan) with

1 cm2 quartz cell. Emission properties were studied by

using Shimadzu RF-6000 spectrofluoro-

photometer (Japan). FTIR spectra were assessed in the

400 ~ 4000 cm-1

region by using IR Affinity FTIR, (Shimadzu, Japan). The AFM analysis was

obtained by using NT-MDT (Ntegra Aura, NTMDT Co, Russia). FESEM

analysis were taken by FESEM – (SIGMA HV –

Carl Zeiss, Bruker Quantax 200 – Z10 EDS Detector). Raman

analysis was performed by a micro Raman spectrometer (Horiba Jobin-LabRam-HR

UV-vis μ-Raman spectrometer, Finland) at ambient temperature with Argon laser

with an excitation wavelength of 514 nm equipped with CCD detector.

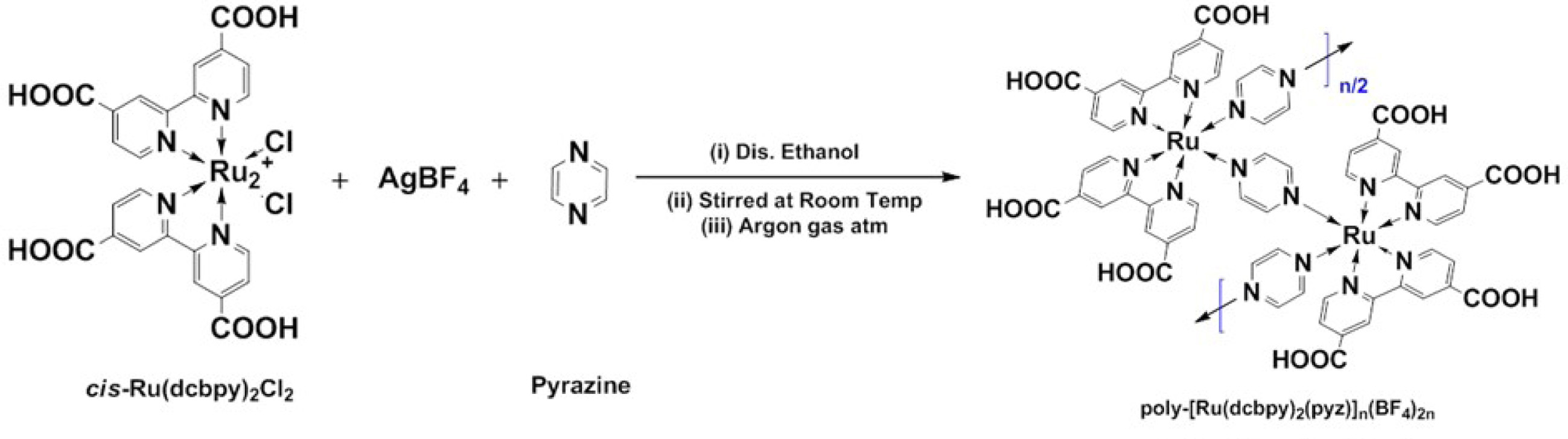

Synthesis

The metal organic polymer (RuMOP-Pyz-1) was

synthesized by a one-pot reaction. The metal organic polymer was obtained by

reacting the mono metallic complex with the linker unit as follows. 5 mL of dry

ethanol solution of Ru(dcbpy)2Cl2 (0.0807 mmol), 5 mL of

AgBF4 (0.1613 mmol) in ethanol was added under argon atmosphere and

stirred for 2 h at room temperature. The precipitated AgCl was filtered and to

the obtained solution, 5 mL of pyrazine (0.0884 mmol) in ethanol was added drop

wise and stirred for 1 h. The metallo-polymer was filtered, washed with ethanol

(50 mL). Further purification was obtained by treating it with N-methyl

pyrrolidine (NMP) and precipitating it with addition of diethyl ether. Finally,

the precipitated metallo-polymer was dried under vacuum at 40 oC

for 8 h. The metal organic polymer (RuMOP-Pyz-1) was obtained as

a dark red-brown solid (yield: 97%). The detailed synthetic pathway was

illustrated in Scheme 1.

Analysis of [Ru(II)(dcbpy)2(pyrazine)]n(BF4)2n]

(RuMOP-Pyz-1): UV-Vis

(3.5 × 10-5 M

in Ethanol): λmax/nm 535. Emission (λmax)

553 nm excited at 395 nm. Melting Point: >450 ºC. FTIR (KBr disk) ν/cm-1:

3452 (b), 2108 (m), 1984 (m), 1751 (s), 1630 (s), 1604 (s), 1513 (s), 1491 (s),

759 (s).

Scheme 1. Depicts the synthesis of poly-[Ru(dcbpy)2(pyz)]n(BF4)2n, coded as (RuMOP-Pyz-1), where (dcbpy) - 2,2'-bipyridyl 4,4'-dicarboxylic acid, (pyz) - pyrazine (linker unit), cis-Ru(II)(dcbpy)2Cl2 - cis-dichlorobis(2,2'-bipyridyl 4,4'-dicarboxylicacid)ruthenium(II) and poly-Ru(dcbpy)2(pyrazine)]n(BF4)2n - poly [Ruthenium(II) bis(2,2'-bipyridyl4,4'-dicarboxylicacid) (pyrazine)bis tetrafluroborate)].

Fabrication

of DSSC

Fluorine doped tin oxide glass (FTO) (~7 Ω/sq,

purchased from Sigma Aldrich) plates were cleaned by ultrasonication with

water, isopropanol and finally dried under nitrogen atmosphere. The cleaned

substrate was heated up to 500 ºC for 25 min to remove organic contaminants and

cooled down to room temperature. The compact layer of titania

nanoparticle (pre treatment) was coated by immersing the FTO

plates in a 40 mM aqueous TiCl4 solution at 70 ºC for 30 min

and followed by a series of sintering steps ((i) 325 ºC for 10 min, (ii)

375 ºC for 10 min, (iii) 450 ºC for 15 min, and (iv)

500 ºC for 30 min). Then by using mortar and pestle, P25

TiO2 powder, acetyl acetone, Water and Triton X - 100

ingredients were grinded to paste. Then the prepared paste was

coated on the pretreated (compact layer) FTO substrates by doctor-blade method

and 12 µm thick film (active layer) was achieved. The TiO2 pastes coated

FTO plates were subjected to the above mentioned similar

sintering steps. After cooling to room temperature, the

TiO2 electrodes were sensitized with metallo polymeric

dye (RuMOP-Pyz-1) by immersing the electrode in 20 mM

sensitizer solution in DMF. Similarly photocathode platinum

coated FTO were prepared by using 0.005 M of H2PtCl6

solution. By using spray gun, the prepared solution was spread on cleaned

pre-heated FTO plates at 50 ~ 60 °C. After the coating the slide

was kept on hot plate at 380 °C. In air atmosphere the pretreated plates

were kept in hot plate and the temperature of the hot plate was gradually increased

from 100 °C to 380 °C. The plates were pre-annealed at 380 °C for 30

min and then slowly cooled down to 80 °C in air

atmosphere. The coated plates can be used at any time, by giving the

photocatalytic regeneration activity by pre annealing it on hot

plate at 380 °C for 30 min.

Photovoltaic

characterization

The current-voltage (I-V) characteristics were recorded

by applying an external potential bias to the cell while recording the

generated photocurrent with a Keithley model 2420 digital source meter. The

light source was a 450W xenon lamp (Oriel) equipped with a Schott K113 Tempax

sunlight filter (Praezisions Glas & optic GmbH) in order to match the

emission spectrum of the lamp to the AM 1.5G standard. The metal organic

polymer (RuMOP-Pyz-1) sensitized DSSC was tested under simulated AM1.5G

illumination (power 100 mW cm-2)

using standard 1-Butyl 3-Methyl Imidazolium Iodide [BMII] electrolyte

containing the iodine/tri iodide couple as the redox shuttle.

Synthesis

of metal organic polymer dye (RuMOP-Pyz-1)

The synthesis of RuMOP-Pyz-1 was prepared by

the reaction of cis-dichlorobis(2,2'-bipyridine

4,4'-dicarboxylic acid) ruthenium (II), cis-Ru(dcbpy)2Cl2

with AgBF4 (the chloride is removed by the precipitation of AgCl)

and the metallo-polymer is formed by the reaction with pyrazine

which acts a linker. It is found that the obtained metal

organic polymer is soluble in polar aprotic solvent like DMF, DMSO, etc..

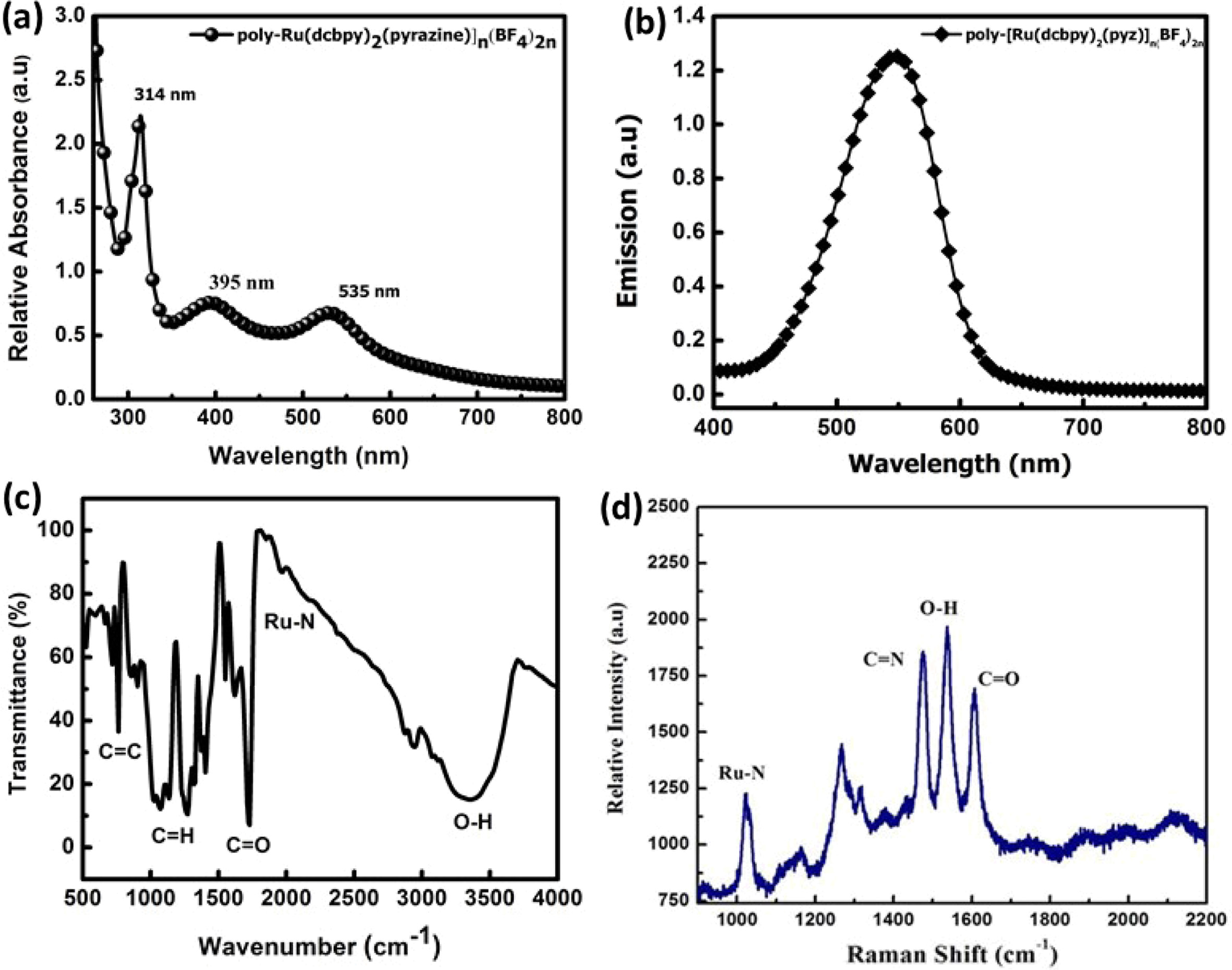

UV-Visible

Spectroscopy

The UV-vis absorption spectrum of the metal organic polymer

(RuMOP-Pyz-1) in DMF solutions were shown in the Fig.

1(a). The absorption spectrum shows a sharp band at 314 nm, which corresponds

to the ligand π - π* transitions [52, 53]. A very

broad and more intense band was obtained in the visible and near

visible regions at 535 nm and 395 nm for the compound RuMOP-Pyz-1

respectively. The bands in the visible and near visible region bands

were assigned to metal-to-ligand charge transfer (MLCT) band of (d - π*) transition

and π - π* transition of the conjugated linking units

respectively. It is worth noting that compared with the other Ru(II)

dicarboxylated based complexes, the synthesized metal organic polymer

showed extended absorption beyond MLCT. The reason for this red

shift could be due to the presence of extended conjugated systems with the

electron withdrawing carboxylic acid groups, which lowers the energy of the π*

orbital of the ligand [54].

Emission

properties

The excitation of RuMOP-Pyz-1 was carried

out at 395 nm and the corresponding emission spectrum was obtained at 553 nm as

shown in Fig. 1(b). This broad emission spectrum is due to the lower π* orbital

of the 2,2'-bipyridyl-4,4'-dicarboxylic acid ligand and it is mainly due to the

presence of electron-withdrawing substituent which is expected to give

the longer lifetime. It has been noted that as the metal extended

π-conjugation increases, a strong and broad

phosphorescence spectrum was obtained [55].

FTIR

and raman spectroscopy

The FTIR spectrum of RuMOP-Pyz-1 in Fig.

1(c) showed a strong band in the region of 3,400 cm-1,

due to the presence of O-H group of the carboxylic acid moiety. The relatively

strong absorption at 1,711 cm-1

corresponds to the stretching vibration mode of C=O bond and the bands at 1,362

cm-1 and

1,603 cm-1

are due to the symmetric and asymmetric stretching in the C=O and C-H bands

respectively. Due to the N-coordination from the pyrazine unit a

stretching vibrational modes at frequency of 2,011 cm-1

for the γ(Ru-N) band was obtained [56]. Furthermore, the C-C bond

linkage in the aromatic skeleton was confirmed by the absorption peak

at 804 cm-1.

The Raman spectrum in Fig. 1(d) was obtained for

the ruthenium (II) dicarboxylated bipyridyl based metal

organic polymeric dye RuMOP-Pyz-1, at an excitation wavelength of 430

nm. The vibration modes at 1,102 cm-1,

1,471 cm-1,

1,539 cm-1, 1,610

cm-1

corresponds to Ru-N, C=N, O-H, C=O groups of the

synthesized metal organic polymer respectively.

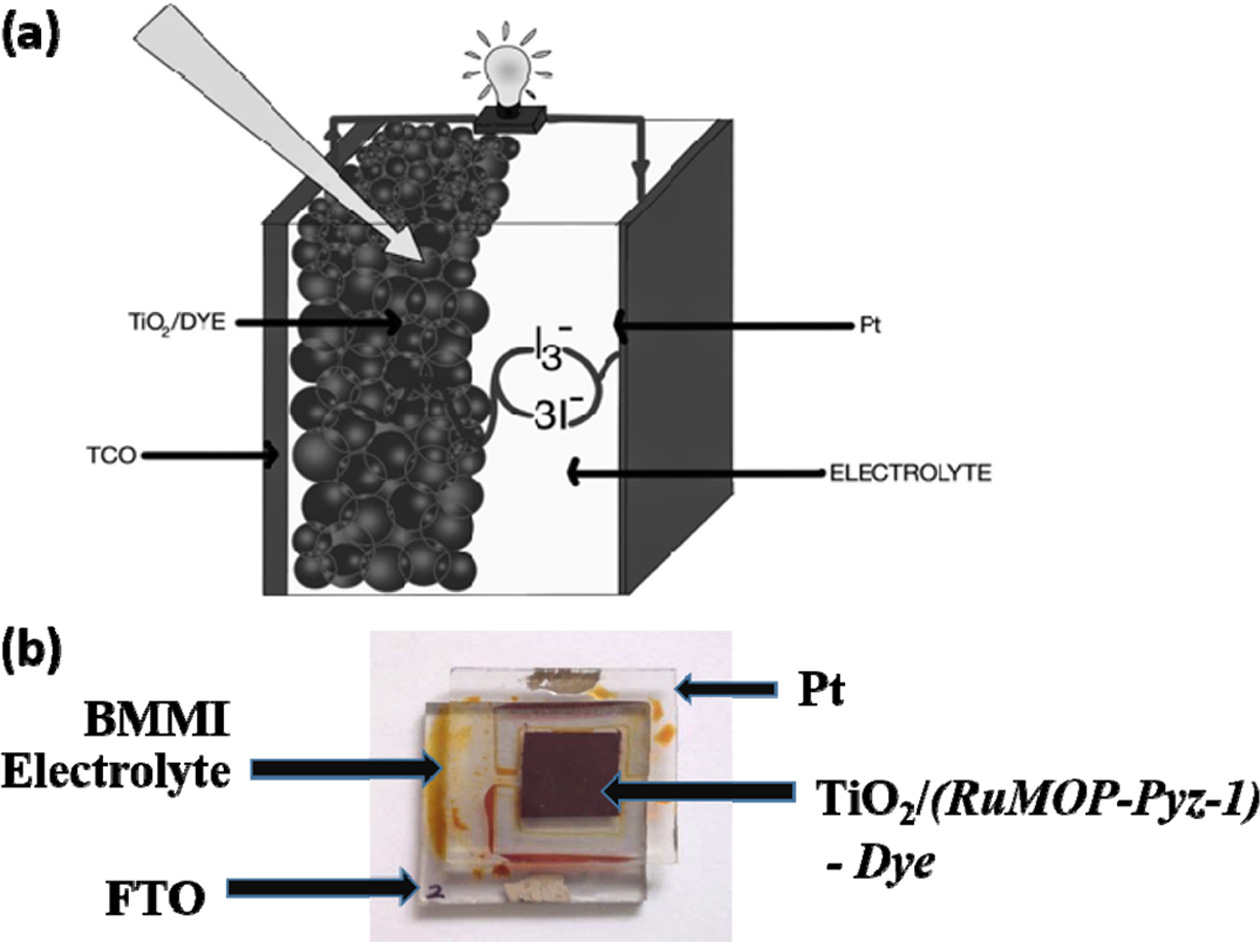

DSSC

Fabrication – Electrode preparation

The typical DSSC and the detailed preparation involved in

each layer of DSSC is as follows, as is given in the Scheme 2. The photo anode

being the nanostructured TiO2 sensitized with the metal organic

polymer dye and photocathode being the Pt coated FTO and the cell was

fabricated with BMII electrolyte as redox couple. With light irradiation, the

sensitizer absorbs the dye and moves to excited state where by shuttling

the electron to TiO2 which in turn pass through

the circuit to photocathode. Further the electrolyte helps in shuttling the

electron from photocathode to dye. The overall efficiency of the device is

deduced using the following equation,

Efficiency (ɳ) = (Voc * Jsc)/(P) * FF (1)

Scheme 2. (a) Schematic representation of typical DSSC device; (b) Real time DSSC device in which the sensitizer is (RuMOPPyz-1) (poly-ruthenium(II)bis(2,2'-bipyridyl4,4'-dicarboxylicacid) (pyrazine)bis(tetrafluroborate) - poly-[Ru(dcbpy)2(pyrazine)]n(BF4)2n).

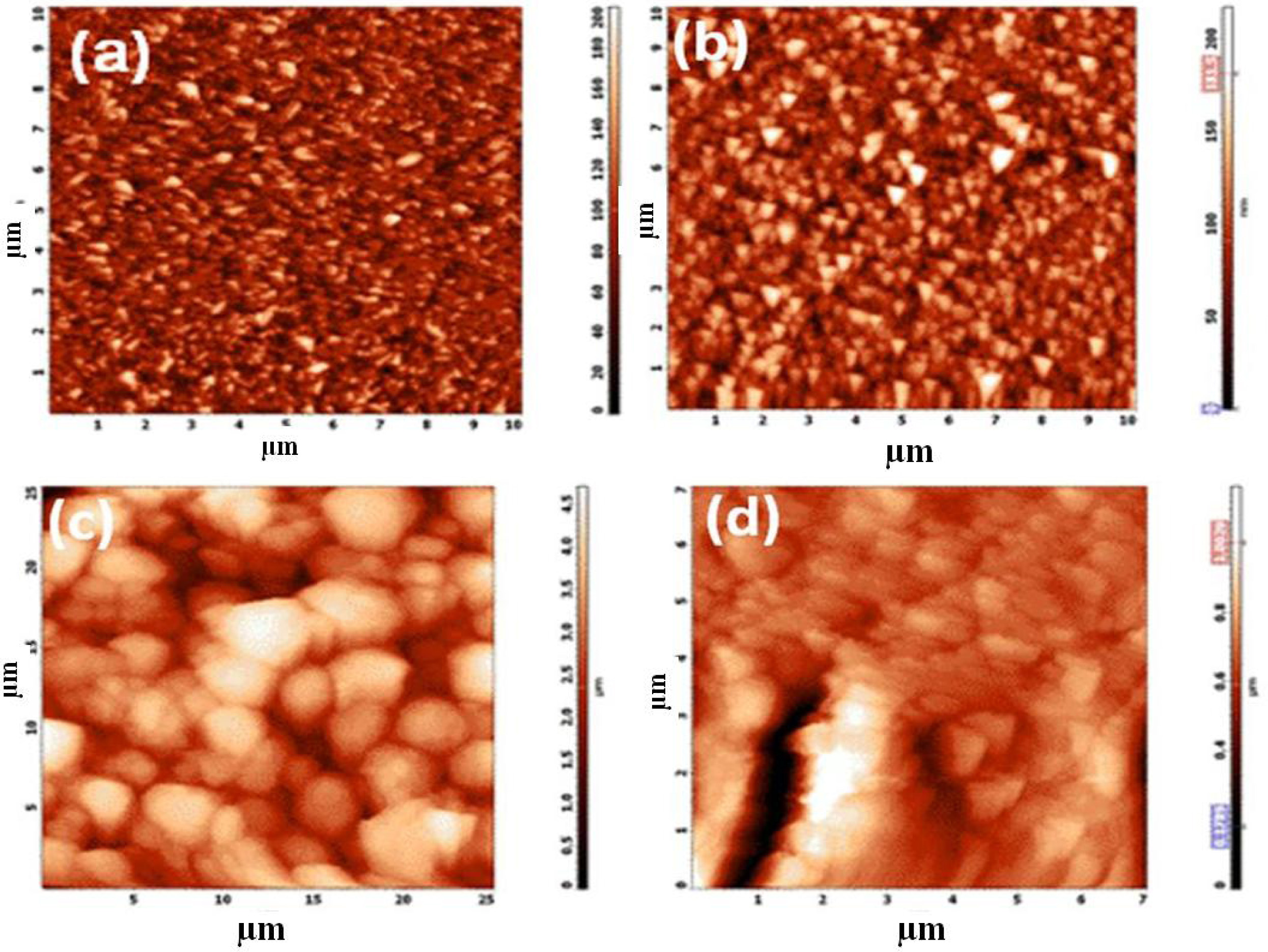

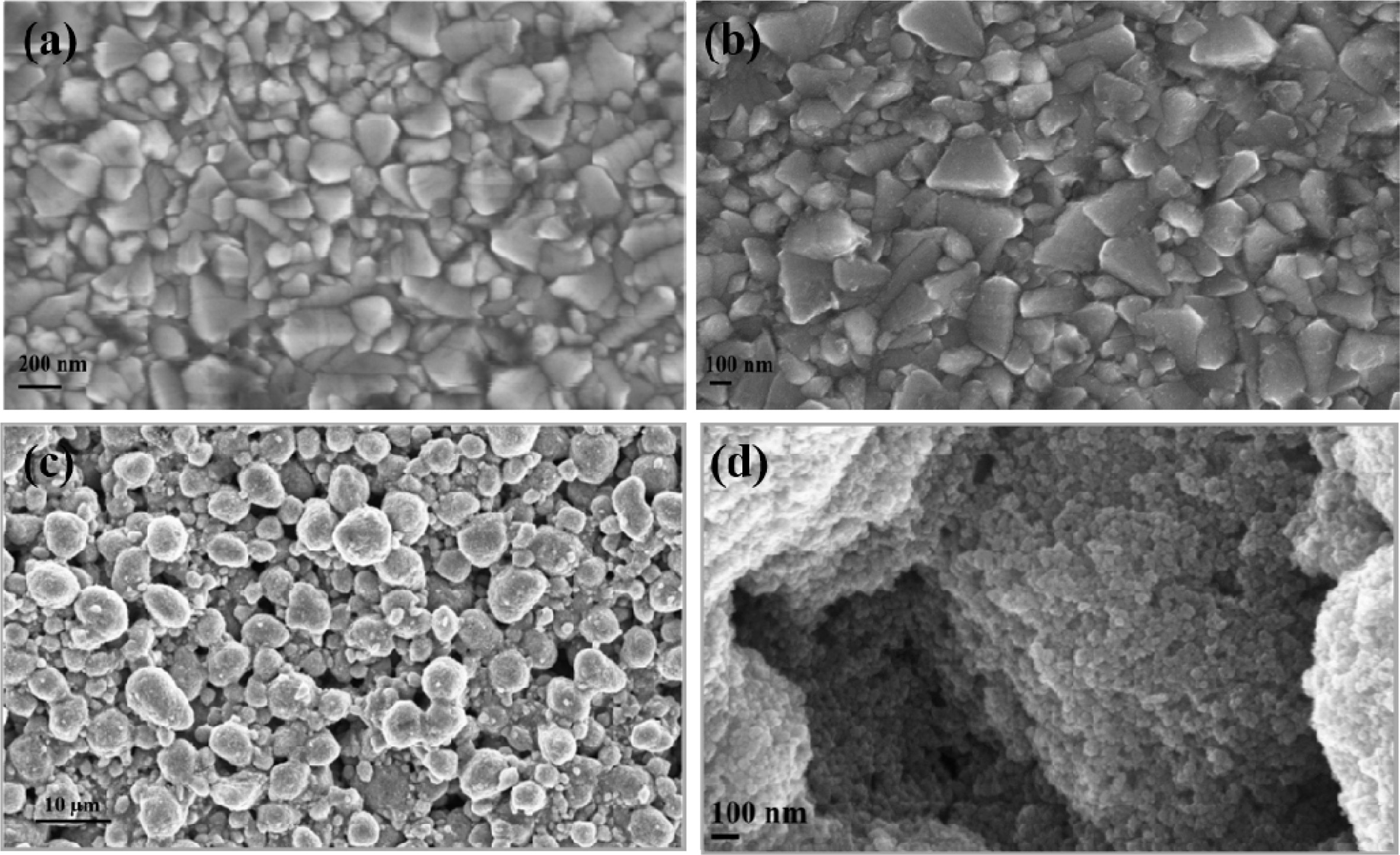

AFM and FESEM analysis

The AFM 2D images of the nanostructured coating of

TiO2 nanoparticles on FTO glass plate and its adsorption

with the metal organic polymer dye RuMOP-Pyz-1 were clearly seen from

the Fig. 2. The surface topo-

graphy of the FTO, compact layer, active layer and dye adsorption were

shown in the Fig. 2(a, b, c & d) respectively. To determine the average

pore size, ImageJ analysis software, were utilized and the average diameter of

the pores in between the TiO2 nanoparticles to be ~10 and ~30 nm for

compact layer and active layer coating of TiO2 nanoparticles . The

root-mean-square roughness (RMS) values of the each layer were 70, 90, 170 and

650 nm. The increased value of RMS indicates that reduced amount reflectivity

of incoming light confirms the formation of TiO2 nanoparticles on

FTO.

The FESEM image of the bare FTO, Compact layer and active

layer coating of nanocrystalline titania on FTO were clearly shown in Fig. 3.

The FTO deposition on glass substrate was shown in Fig. 3(a). The compact layer

of deposition of titania nanoparticle as pretreatment for

the photoanode as barrier layer on FTO was achieved (Fig.

3b) by dipping the FTO plates in a 40 mM aqueous TiCl4

solution and followed by a series of sintering steps. In Fig. 3(c) globular

structures with aggregated nanoparticles were noted on the above of compact

layer as TiO2 photoanode. In particular, Fig. 3(d)

depicts the availability of porosity for the deep penetration of

the dye within TiO2 was observed which enhances the easy electron

transfer from LUMO of the dye to the HOMO of the TiO2

nanoparticles. The available porosity in between the TiO2 nanoparticles

is very essential for the effective dye adsorption.

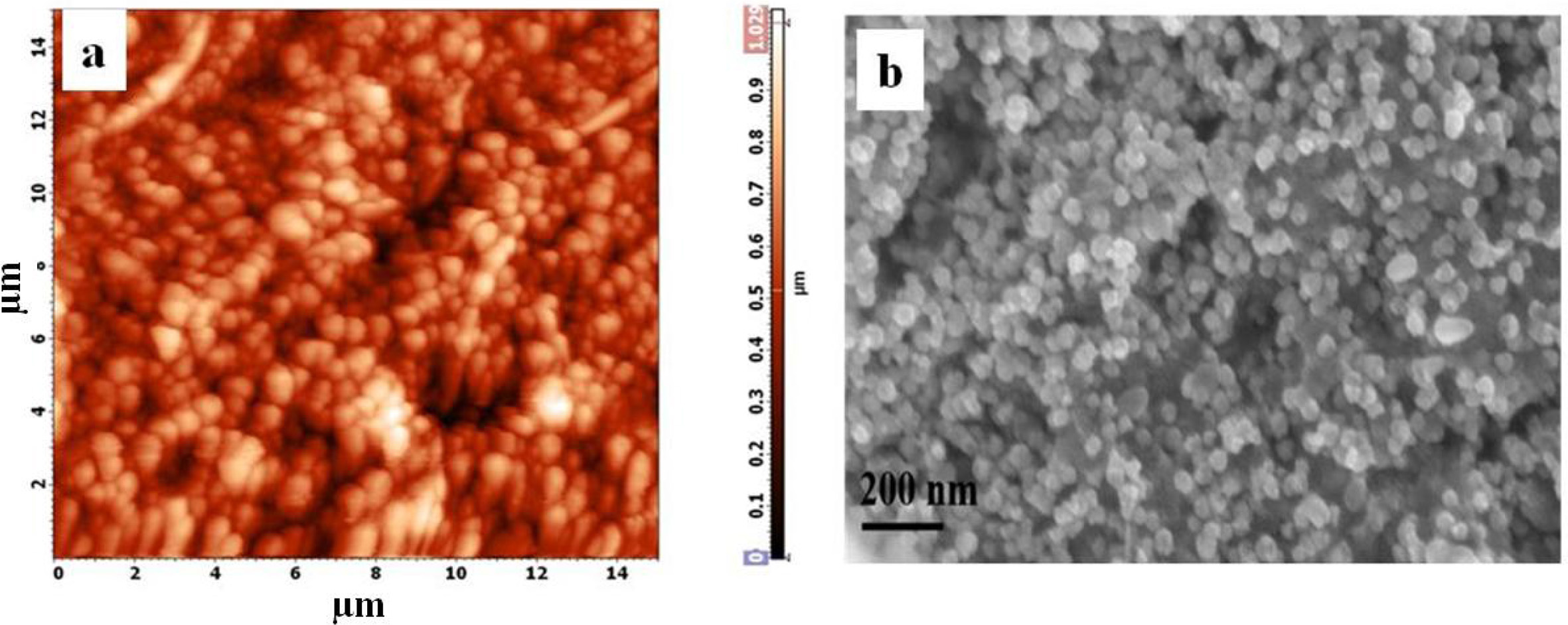

The photo cathode preparation and its corresponding AFM

and FE-SEM images were given in Fig. 4(a & b) respectively. The AFM 2D

image displays the uniform distribution of Pt nanoparticles on FTO. The high

resolution image of the FESEM (Fig. 4b), provides information of the platinum

electrode prepared by spray coating. The layer appears conformal with the conductive

oxide surface and show good layer uniformity. Hence, we

can see how the platinum nanoparticles are localized on the FTO surface.

Importantly, the coated particle was interconnected continuously and produces

highly porous structures of Pt nanoparicles.

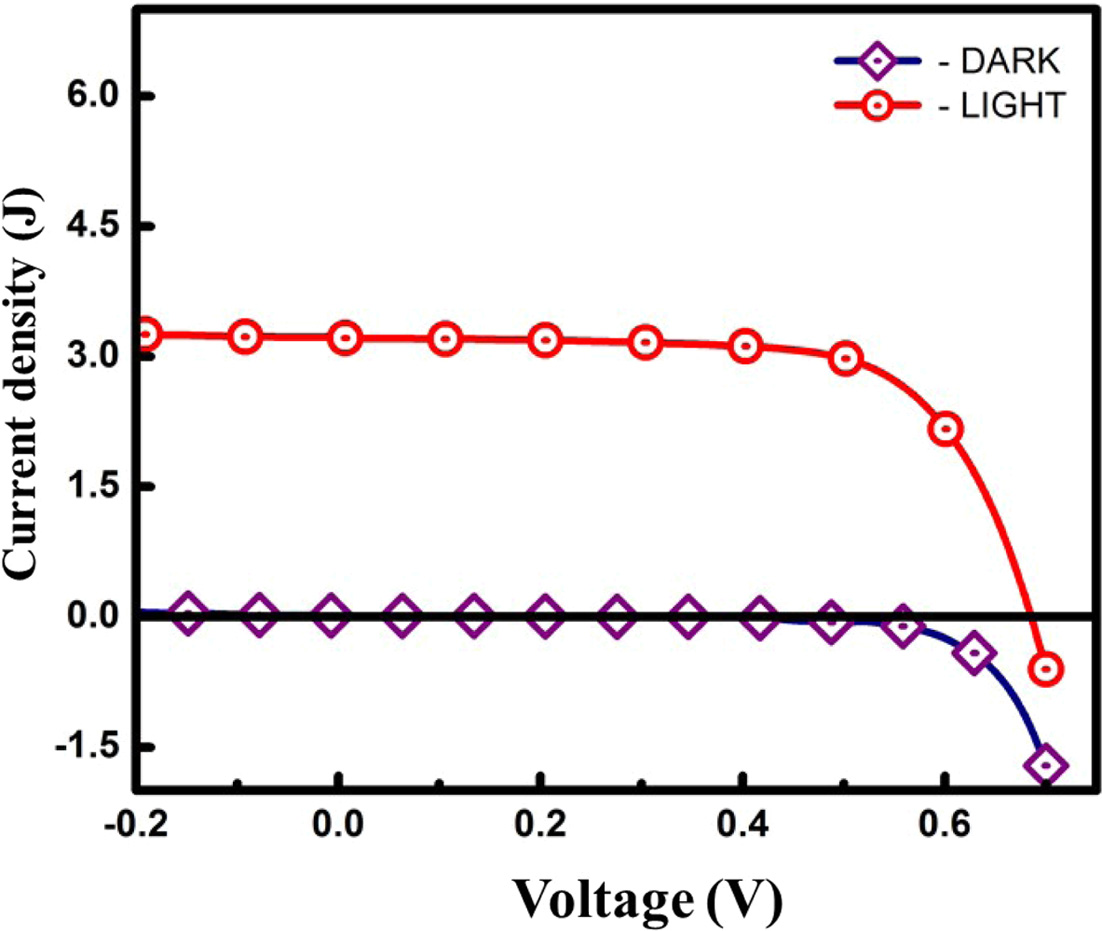

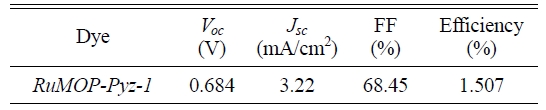

I-V

characteristics

The current density (J) versus voltage (V)

curves of the DSSC is shown in Fig. 5. The photovoltaic measurements

of open circuit voltage (Voc), short circuit current density

(Jsc), fill factor (FF), and the PCE (ɳ) values

were shown in Table 1. The DSSC fabricated with the synthesized metal organic

polymer (RuMOP-Pyz-1), exhibited the photo

conversion efficiency value (ɳ) of 1.51% with short

circuit current (Jsc) 3.22 mA/cm2; open circuit

voltage (Voc) 0.684 V and Fill Factor (FF)

68.45%. When compared to the reported ruthenium dyes, 2,2'-bipyridine

4,4'-dicarboxylic acid based supramolecular ruthenium main-chain metal organic

polymer which has pyrazine conjugated bridging ligand

acting as linker unit, has better photovoltaic properties.

By using linear ligands through the conjugated linker

units, the charge separation distance and the charge

recombination effects in DSSCs can be controlled. Normally,

the carboxylic group in dcbpy moiety will be attached to the TiO2 surface

and thus by acting an electron withdrawing substituent in the bipyridine

ligand. So, in this synthesized metal organic polymer which has more number of

dicarboxylic acid group (dcbpy) throughout the polymer provides the necessary coupling

of the LUMO level of dye with the conduction band of

titanium dioxide, in order to promote efficient quantum injection.

|

Fig. 1 (a) UV-Vis spectra of (RuMOP-Pyz-1) in DMF; (b) Emission spectrum (RuMOP-Pyz-1) in DMF; (c & d) FTIR and Raman Spectrum of (RuMOP-Pyz-1) respectively. |

|

Fig. 2 AFM 2D - Images of (a) Bare FTO; (b) Compact Layer of Nanocrystalline TiO2 (c) Active layer photoanode; (d) (RuMOP-Pyz-1) dye adsorbed on TiO2 active layer respectively. |

|

Fig. 3 FESEM Images of nanocrystalline TiO2 photoanode (a) Bare FTO; (b) Compact Layer; (c) Active layer; (d) Porosity on TiO2 active layer respectively. |

|

Fig. 4 (a) 2D AFM image and (b) FESEM image of platinum photocathode respectively. |

|

Fig. 5 Photovoltaic curve (J-V) measurements of fabricated DSSC device in which (RuMOP-Pyz-1) as sensitizer. (DARK - without sunlight, LIGHT - under Air Mass (AM) 1.5 G simulated sunlight at a light intensity of 100 mW/cm2) |

In summary, [Ru(II)(dcbpy)2(pyz)]n(BF4)2n

based metal organic polymer (RuMOP-Pyz-1) was

successfully synthesized and employed as a sensitizer in DSSC.

The synthesized metal organic polymer was characterized using

various spectroscopic and microscopic techniques. A maximum

conversion efficiency of 1.51% with short circuit current (Jsc)

3.22 mA/cm2; open circuit voltage (Voc) 0.684 V

and Fill Factor (FF) 68.45% under Air Mass (AM) 1.5 G simulated sunlight at

a light intensity of 100 mW/cm2 was obtained. The efficiency of the

device and its photovoltaic performances were found to be

satisfactory. The enhanced performance of the device is

attributed to the presence of extended conjugation of the metallo polymer which

helps in a facile electron transfer from the HOMO to LUMO of TiO2.

The results reported in this paper can provide new insights in

improving the performance of DSSC in future.

The authors wish to acknowledge the facilities and support

provided by PSG Sons & Charities Coimbatore, India.

- 1. B. O’ Regan and M. Gratzel, Nature 353 (1991) 737-740.

-

- 2. M.K. Nazeeruddin, R. Splivallo, P. Liska, P. Comte, and M. Grätzel, Chem. Commun. 12 (2003) 1456-1457.

-

- 3. M. Grätzel, Accounts. Chem. Res. 42 (2009) 1788-1798.

-

- 4. J.B. Baxter, J. Vac. Sci. Tech. A. 30 (2012) 020801.

-

- 5. A. Hagfeldt, G. Boschloo, L. Sun, L. Kloo, and H. Pettersson, Chem. Rev. 110 (2010) 6595-6663.

-

- 6. T.L. Bahers, E. Brémond, I. Ciofini, and C. Adamo, Phys. Chem. Chem. Phys. 16 (2014) 14435-14444.

-

- 7. A.S. Polo, M.K. Itokazu, and N.Y.M. Iha, Coordin. Chem. Rev. 248 (2004) 1343-1361.

-

- 8. A. Yella, H-W. Lee, H.N. Tsao, C. Yi, A.K. Chandiran, M.K. Nazeeruddin, E. Diau, C.Y. Yeh, S.M. Zakeeruddin, and M. Gratzel, Science 334 (2011) 629-634.

-

- 9. A. Carella, F. Borbone, and R. Centore, Front. Chem. 6 (2018) 481.

-

- 10. J. Albero and P. Atienzar, A. Corma, H. Garcia, Chem. Rec. 15 (2015) 803-828.

-

- 11. J.N. Clifford, E. Martínez-Ferrero, A. Viterisi, and E. Palomares, Chem. Soc. Rev. 40 (2011) 1635-1646.

-

- 12. L. Loh and S. Dunn, J. Nanosci. Nanotechno. 12 (2012) 1-16.

-

- 13. W. Wunderlich, T. Oekermann, L. Miao, N.T. Hue, S. Tanemura, and M. Tanemura, J. Ceram. Process. Res. 5 [4] (2004) 343-354.

- 14. C.-P. Lee, K.-M. Lee, P.-Y Chen, and K.-C. Ho, Sol. Energ. Mat. Sol. C. 93 (2009) 1411-1416.

-

- 15. H.S. Chen, S.J. Lue, Y.L. Tung, K.W. Cheng, F.Y. Huang, and K.C. Ho, J. Power. Sources. 196 (2011) 4162-4172.

-

- 16. Liu, Yalin Lu, Z.B. Xie, and G.M. Chow, Sol. Energ. Mat. Sol. C. 95 (2011) 800-803.

-

- 17. G. Monros, M. Llusar, A. García, C. Gargori, and R. Galindo. Adv. Sci. Tech. 68 (2010) 182-193.

-

- 18. S.I. Noh, T-Y. Seong, and H-J. Ahn, J. Ceram. Process. Res. 13 [4] (2012) 491-494.

- 19. H. An, G-H. An, and H-J. Ahn, J. Ceram. Process. Res. 16 [2] (2015) 208-212.

- 20. S.I. Noh and H-J. Ahn, J. Ceram. Process. Res. 13 (2012) s1-s5.

- 21. W-S. Kwack, H-J. Choi, W-C. Choi, H-R Oh, S -Y Shin, K. Moon, J-Y Kwak, Y-K. Jeong, S-H. Kwon. J. Ceram. Process. Res. 13[3] (2012) 338-342.

- 22. H. Lee, J-I. Park, T-H. Kim, and K-B. Park. J. Ceram. Process. Res. 14[3] (2013) 405-409.

- 23. F. Shao, J. Sun, L. Gao, S. Yang, J. Luo. J. Phys. Chem. C 115[5] (2011) 1819-1823

- 24. L. Shi, X. Liu, H. Li, and G. Xu. Anal. Chem. 78 (2006) 7330-7334.

-

- 25. S.Y. Tsai, C.T. Ni, and K.Z. Fung. Ceram. Int. 43 (2017) S460-S463.

-

- 26. S. Ahmada, A.K. Pandey, N.A. Rahima, S. Shahabuddinb, and S.K. Tyagi Ceram. Int. 44[15] (2018) 18444-18449.

-

- 27. M.I. Khana, M.A. Rehman, M. Saleem, M.R. Baig, S. Rehman, W.A. Farooq, M. Atif, and A. Hanif, Ceram. Int. 45[16] (2019) 20589-20592.

-

- 28. T. Oku, S. Nagaoka, A. Suzuki, K. Kikuchi, Y. Hayashi, H. Sakuragi, and T. Soga, J. Ceram. Process. Res. 9[6] (2008) 549-552.

- 29. Y. Ren, D. Sun, Y. Cao, H.N. Tsao, Y. Yuan, S.M. Zakeeruddin, P. Wang, and M. Gratzel, J. Am. Chem. Soc. 140[7] (2018) 2405-2408.

-

- 30. N.A. Ludin, A.M. Mahmoud, A.B. Mohamad, A.A.H. Kadhum, K. Sopian, and N.S. Abdul Karim, Renew. Sust. Energ. Rev. 31 (2014) 386-396.

-

- 31. Y.S. Yen, H.H. Chou, Y.C. Chen, C.Y. Hsu, and J.T. Lin, J. Mater. Chem. 22 (2012) 8734-8747.

-

- 32. W.Y. Wong, J. Organomet. Chem. 694 (2009) 2644-2647.

-

- 33. N. Kakuta, T. Oku, A. Suzuki, K. Kikuchi, and S. Kikuchi, J. Ceram. Process. Res. 13[1] (2012) 28-31.

- 34. C.A. Bignozzi, R. Argazzi, R. Boaretto, E. Busatto, S. Carli, F. Ronconi, and S. Caramori, Coordin. Chem. Rev. 257 (2013) 1472-1492.

-

- 35. S. Sethi, S. Jena, P.K. Das, and N. Behera, J. Mol. Struc. 1193 (2019) 495-521.

-

- 36. S.S. Mali, C.A. Betty, P.N. Bhosale, and P.S. Patil, Electrochim. Acta. 59 (2012) 113-120.

-

- 37. C. Cai, S. Tseng, M. Kuo, K. Lin, H. Yang, and R. Lee RSC. Adv. 5 (2015) 102803-102810.

-

- 38. B. Nagarajan, S. Kushwaha, R. Elumalai, S. Mandal, K. Ramanujam, and D. Raghavachari, J. Mater. Chem. A. 5 (2017) 10289-10300.

-

- 39. T. Daeneke, T.H. Kwon, A. B. Holmes, N. W. Duffy, U. Bach, and L. Spiccia, Nat. Chem. 3 (2011) 211-215.

-

- 40. Q. Jiang, Z. Chu, P. Wang, X. Yang, H. Liu, Y. Wang, and J. You, Adv. Mater. 29 (2017) 1703852.

-

- 41. B. Hailegnaw, S. Kirmayer, E. Edri, G. Hodes, and D. Cahen, J. Phys. Chem. Lett. 6 (2015) 1543-1547.

-

- 42. P. Billen, E. Leccisi, S. Dastidar, S. Li, L. Lobaton, S. Spatari, and J. B. Baxter, Energy, 166 (2018) 1089-1096.

-

- 43. S. Yun, Y. Qin, A.R. Uhl, N. Vlachopoulos, M. Yin, D. Li, and A. Hagfeldt, Energy Environ. Sci. 11 (2018) 476-526.

-

- 44. R. Su, S. Ashraf, and A. El-Shafei, Sol. Energy 177 (2019) 724-736.

-

- 45. J.A. Cuello-Garibo, C.C. James, M.A. Siegler, and S. Bonnet, Eur. J. Inorg. Chem. 25 (2018) 1260-1268.

-

- 46. J.C. Salsman, S. Ronco, C.H. Londergan, and C.P. Kubiak, Inorg. Chem. 45 (2006) 547-554.

-

- 47. Q. Yu, S. Liu, M. Zhang, N. Cai, Y. Wang, and P. Wang, J. Phys. Chem. C 113 (2009) 14559-14566.

-

- 48. D. Bari, N. Wrachien, R. Tagliaferro, S. Penna, T.M. Brown, and A. Reale, A. Cester, Microelectron. Reliab. 51 (2011) 1762-1766.

-

- 49. A. Wild, A. Winter, and F. Schlütter, U. S. Schubert, Chem. Soc. Rev. 40 (2011) 1459-1511.

-

- 50. K. Feng, X. Shen, Y. Li, Y. He, D. Huang, and Q. Peng, Polym. Chem. 4 (2013) 5701-5710.

-

- 51. J. Xiang, C.L. Ho, and W.Y. Wong, Polym. Chem. 6 (2015) 6905-6930.

-

- 52. A.L.A. Parussulo, T.A. Matias, R.R. Guimaraes, S.H. Toma, K. Araki, and H.E. Toma, Inorg. Chim. Acta, 453 (2016) 764-770.

-

- 53. A.M.W.C. Thompson, M.C.C. Smailes, J.C. Jeffery, and M.D.J. Ward, J. Chem. Soc. Dalton Trans. (1997) 737-744.

-

- 54. M. Plevoets, F. Vögtle, L. De Cola, and V. Balzani, New J. Chem. 23 (1999) 63-69.

-

- 55. M.K. Nazeeruddin, S.M. Zakeeruddin R.H. Baker, M. Jirousek, P. Liska, N. Vlachopoulos, V. Shklover, C-H. Fischer, and M. Gratzel, Inorg. Chem. 38[26] (1999) 6298-6305.

-

- 56. C.A. Mitsopoulou, I. Veroni, A.I. Philippopoulos, and P. Falaras, J. Photoch. Photobio. A. 191 (2007) 6-12.

-

This Article

This Article

-

2020; 21(1): 123-130

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.123

- Received on Dec 9, 2019

- Revised on Dec 15, 2019

- Accepted on Dec 24, 2019

Services

Services

- Abstract

introduction

experimental section

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Sivasubramanian Ramanathan

-

Electrochemical Energy Materials and Sensors Laboratory, NRIIC, PSG Institute of Advanced Studies, Coimbatore-4, Tamilnadu, India

Tel : +422 434 4000 Fax: +422 257 3833 - E-mail: rss@psgias.ac.in

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.