- Wet preparation of calcium phosphates from aqueous solutions

Byeong Woo Lee* and Il Gok Hong

Dept. of Ocean Advanced Materials Convergence Engineering, Korea Maritime and Ocean University, Busan 49112, Korea

Abstract. Calcium phosphates such as HA (hydroxyapatite), β-TCP (tricalcium phosphate) and biphasic HA/β-TCP, were synthesized

by wet chemical precipitation in aqueous solution combined with ball milling

process. Nanosize powders of the calcium phosphates were synthesized using

Ca(OH)2 and H3PO4. The effects of initial precursor Ca/P ratio (1.30, 1.50 and 1.67),

ball milling process and post heat-treatment on the phase evolution behavior of

the powders were investigated. The phase of resulting powder was controllable

by adjusting the initial Ca/P ratio. HA was the only phase for as-prepared

powders in both cases of Ca/P ratios of 1.50 and 1.67. The single HA phase

without any noticeable second phase was obtained for the initial Ca/P ratio of

1.67 in the overall heat-treatment range. Pure β-TCP and biphasic calcium phosphate (HA/β-TCP) were synthesized from precursor solutions having Ca/P molar ratios of 1.30 and 1.50, respectively, after having been heat-treated above 700 oC. The β-TCP phase has appeared on the pre-existing DCPD (dicalcium

phosphate dihydrate) and/or HA phase. Dense ceramics having translucency were

obtained at a considerably lower sintering temperature. The modified process

offered a fast, convenient and economical route for the synthesis of calcium phosphates.

Keywords: Calcium phosphate, Hydroxyapatite, Tricalcium phosphate, Nanopowder, Wet chemical synthesis

Calcium phosphates have

been widely utilized in biological applications. Among the

calcium phosphates, significant attention has been given to

hydroxyapatite (HA, Ca10(PO4)6(OH)2) and tricalcium phosphate (β-TCP,

Ca3(PO4)2) due to their

prominent bioactivity and biocompatibility [1-4]. Over the past few decades, the biphasic calcium phosphate

(BCP) composed of both the tricalcium phosphate (β-TCP)

and hydroxyapatite (HA) has also received considerable attention due to its

enhanced biocompatibility and mechanical properties [5-7].

Recently, nanometer-sized calcium

phosphates have received much attention due to

their significantly enhanced

efficacy [1, 6]. Solution processes have been widely used

to prepare nanometer-sized powders.

Wet chemical precipitation using aqueous solutions

is the most common synthesis route for the preparation of calcium phosphates nanoparticles, which provides additional advantageous

features such as simple, low cost and

low temperature synthesis [8-10].

Calcium hydroxide (Ca(OH)2) and phosphoric acid

(H3PO4) were widely used as

starting materials for the precipitation process for HA

and β-TCP preparation according to the reactions, Eq. (1) and (2), respectively. The only byproduct of the reactions is water, and the reactions

involve no foreign elements.

10 Ca(OH)2 + 6 H3PO4 → Ca10(PO4)6(OH)2

(HA) + 18 H2O (1)

3 Ca(OH)2+ 2 H3PO4 → Ca3(PO4)2

(TCP) + 6 H2O (2)

The properties of particles prepared by the wet synthesis

method are largely dependent on

process parameters. The phase, size, shape, and surface area of the particles obtained by

the wet process are highly sensitive to the

precursor concentration, Ca/P ratio

of precursors, and reaction pH [5, 11]. Furthermore, the phosphoric acid addition rate is strongly linked

to the suspension stabilization, and also to the final precipitate (powder) properties

[12, 13]. The precipitation chemistry for the preparation of calcium

phosphates has been found to be complicated due to the slow attainment of equilibrium and the amorphous nature of the

products formed. It is also very important to obtain a large amount of products at a

constant reactant volume.

The present study

deals with the modified synthesis of

calcium phosphate powders using a wet precipitation method combined with mechanical ball milling process. In this study, calcium hydroxide was used as a calcium

precursor and phosphoric acid was added as a source of phosphorus according to Eq.

(1) and (2). This work is concerned with a more convenient approach to the

preparation of calcium phosphate compounds such as pure β-TCP, biphasic calcium phosphate (HA/β-TCP) and pure HA, from precursor Ca/P molar

ratios of 1.30, 1.50

and 1.67, respectively, using precursor solutions with

higher concentrations than other wet preparation processes. In order to clarify the effect of precursor Ca/P ratio on the powder

properties, this study has been carried out without any capping or pH control

agents. Nanoscale calcium phosphate powders

were synthesized via the

precipitation process combined with a ball milling process, and the feasibility

of the process for large-scale production at high production rates was

discussed.

Calcium phosphate nanoparticles were prepared by a wet

precipitation route followed by ball milling process under

controlled synthesis conditions. Calcium hydroxide (Ca(OH)2) and

phosphoric acid (H3PO4) were used as precursors.

In the process, 85% of H3PO4 solution was added dropwise

into 275 ml of a high concentration (1 M) of Ca(OH)2 aqueous suspension solutions

within 20 min. For the preparation of the different calcium

phosphates, the predetermined Ca/P molar ratio of the

solutions of 1.30, 1.50 and 1.67 was set by adding

the H3PO4

solution to the continuously stirred Ca(OH)2 suspension at room temperature. The precipitation products with the mother solution were ball milled at 250 revolutions per minute. After the ball milling process up to 12 h, the synthesized powders were dried at 60 oC for 12 h. Unlike other preparation processes for calcium

phosphates, there was no maturing

(aging) and filtering (washing) process involved.

The prepared powders were calcined at different

temperatures ranging from 500 oC to 900 oC to study phase

developments. The dried powders were

formed to pellets, and then sintered at 1,100 oC for 2 h. The properties for the powders

and sintered ceramics were characterized

using scanning electron microscopy (SEM) and X-ray diffraction (XRD) using Cu Kα

radiation (λ = 1.5418 Å). The

particle sizes of the synthesized powders were also

calculated by the XRD peak broadening according to the Scherrer’s equation (Dcal

(particle size) = 0.89 λ/(B cos θ):

where λ is the wavelength, B is the full width at half maxima (FWHM) in radians

and θ is the

diffraction angle).

In the present study, calcium

phosphates such as β-TCP, biphasic

calcium phosphate (HA/β-TCP) and HA were prepared by a

new approach of the aqueous precipitation method, which was combined with mechanical ball milling process, from precursor Ca/P

ratios of 1.30, 1.50 and 1.67, respectively. As the Ca/P ratio decreased from 1.67 to 1.30, the

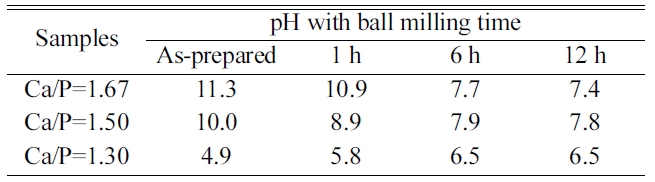

pH after the precipitation reaction decreased from 11.3 to 4.9, due to the lowered base/acid ratios in the solutions. Changes in the pH value of

the solutions as-precipitated and after the ball

milling process are given in Table 1. The initial pH

value of the solution after precipitation was

measured to be 11.3 and the value decreased

to 7.4 after the ball milling process for Ca/P

molar ratio of 1.67. The pH values of biphasic HA/β-TCP also decreased from 10.0 to 7.8 at Ca/P molar ratio 1.5. This decrease in pH values was due to the completion of the chemical reactions of the unreacted precursors through the ball milling process forming HA (i.e. calcium

phosphate-hydroxide) with consumption

of free hydroxide (OH-) in the reactant solution in accordance with Eq. (1). In contrast, for β-TCP

powders from Ca/P molar ratio of 1.30, the pH value was

increased from 4.9 to 6.5 with increasing ball milling time,

because, after the precipitation reaction progressed,

water having the higher pH value (~7) was formed from the lower pH precursor

solution, following Eq. (2).

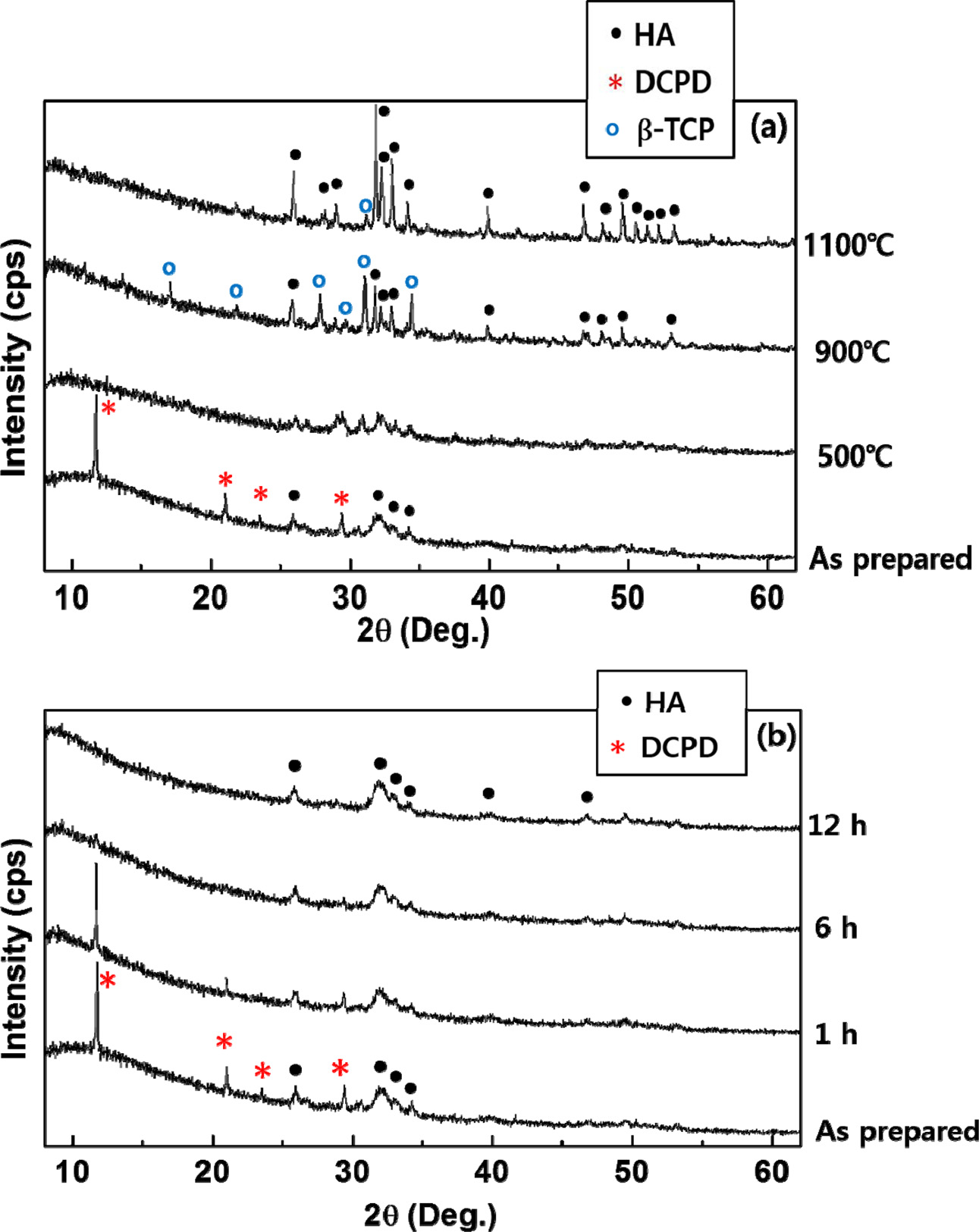

The effect of ball milling on the phase pure HA

preparation is presented in Fig. 1. When the powder

was prepared in a short period of precursor mixing time within 10 min from Ca/P

of 1.67, the predominant phase of the precipitate was mostly undesirable DCPD (CaHPO4·2H2O (JCPDS 11-293)). Once the DCPD appeared, the phase was quite stable.

To turn the phase into the desired HA phase (hexagonal HA (JCPDS 9-432)), a

heat-treatment up to 1,100 oC

was required as shown in Fig. 1(a). Even after the high temperature heat

treatment, it was difficult to obtain the phase pure HA. On the contrary, the

phase pure HA phase can be synthesized by the simple ball milling process. As

can be seen in Fig. 1(b), there was a drastic phase change from DCPD to HA by

ball milling process. To prepare the single HA phase

precipitate, about 6 hours of ball milling

was required. On the other hand, the β-TCP phase (JCPDS 9-169) could not be

easily synthesized by ball milling process using the precipitates from the

precursor Ca/P ratios of 1.30 and

1.50, and subsequent heat treatment was necessary to prepare biphasic HA/β-TCP

and phase pure β-TCP.

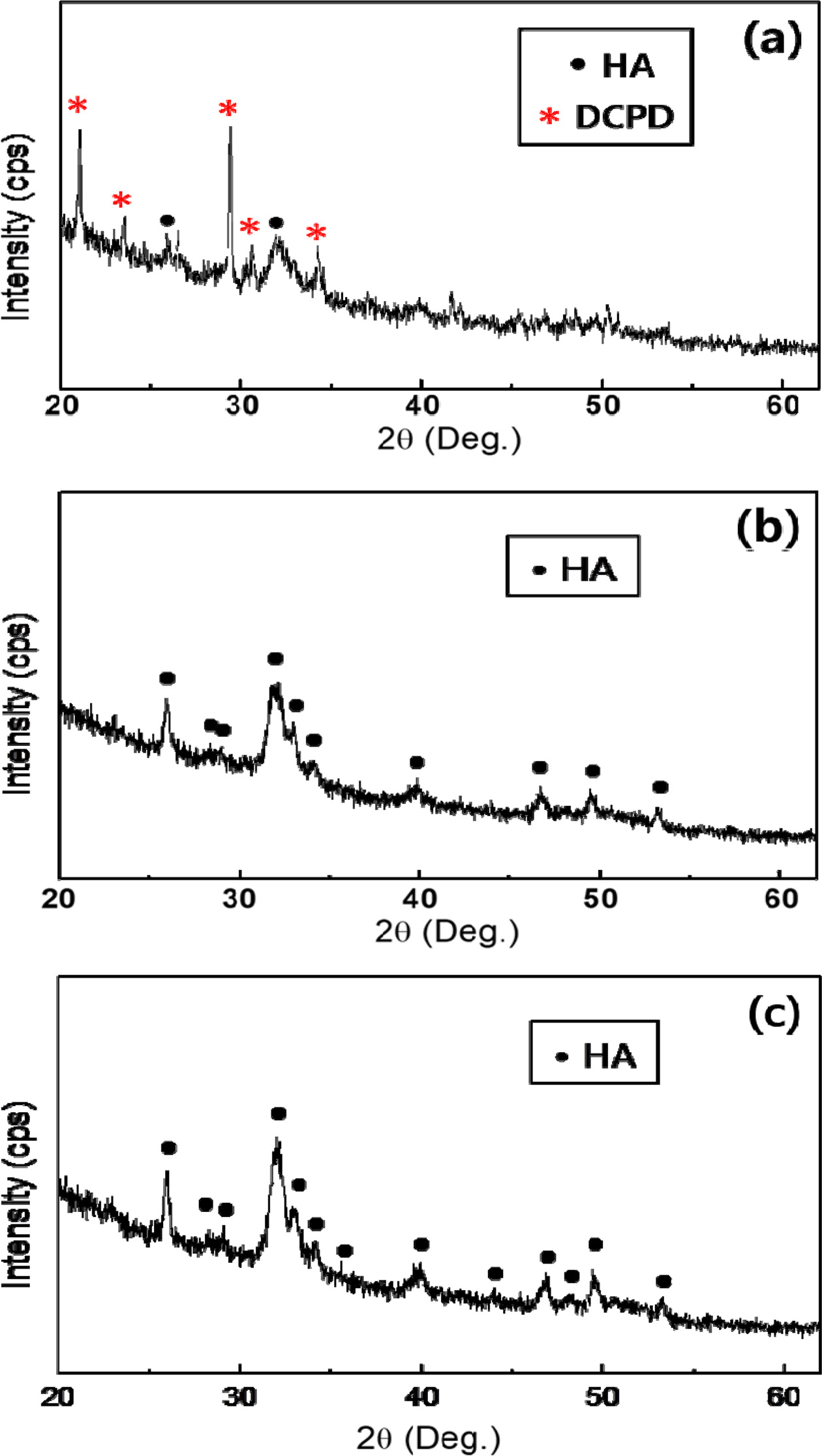

Fig. 2 shows the

XRD patterns of the

calcium phosphate powders after ball milling for 12 h, from the precursor Ca/P ratios of

1.30, 1.50 and 1.67. A mixed phase of DCPD with HA phase was obtained with Ca/P ratio of 1.30.

For the precursor Ca/P ratios of 1.50 and 1.67, the patterns are

showing only the HA phase formed without other

phases. There is no noticeable difference between the peaks for the precipitates prepared. In addition, the broad and weak intensity of the HA peaks indicates poor crystallinity and/or nanometer scale

crystallites of the

calcium phosphate powders prepared. The

prepared powders are approximately 26 nm in particulate size

for both cases calculated by the Scherrer’s

equation. The most distinct (002) reflections (near 2θ 26o) in the

XRD patterns were taken into calculation.

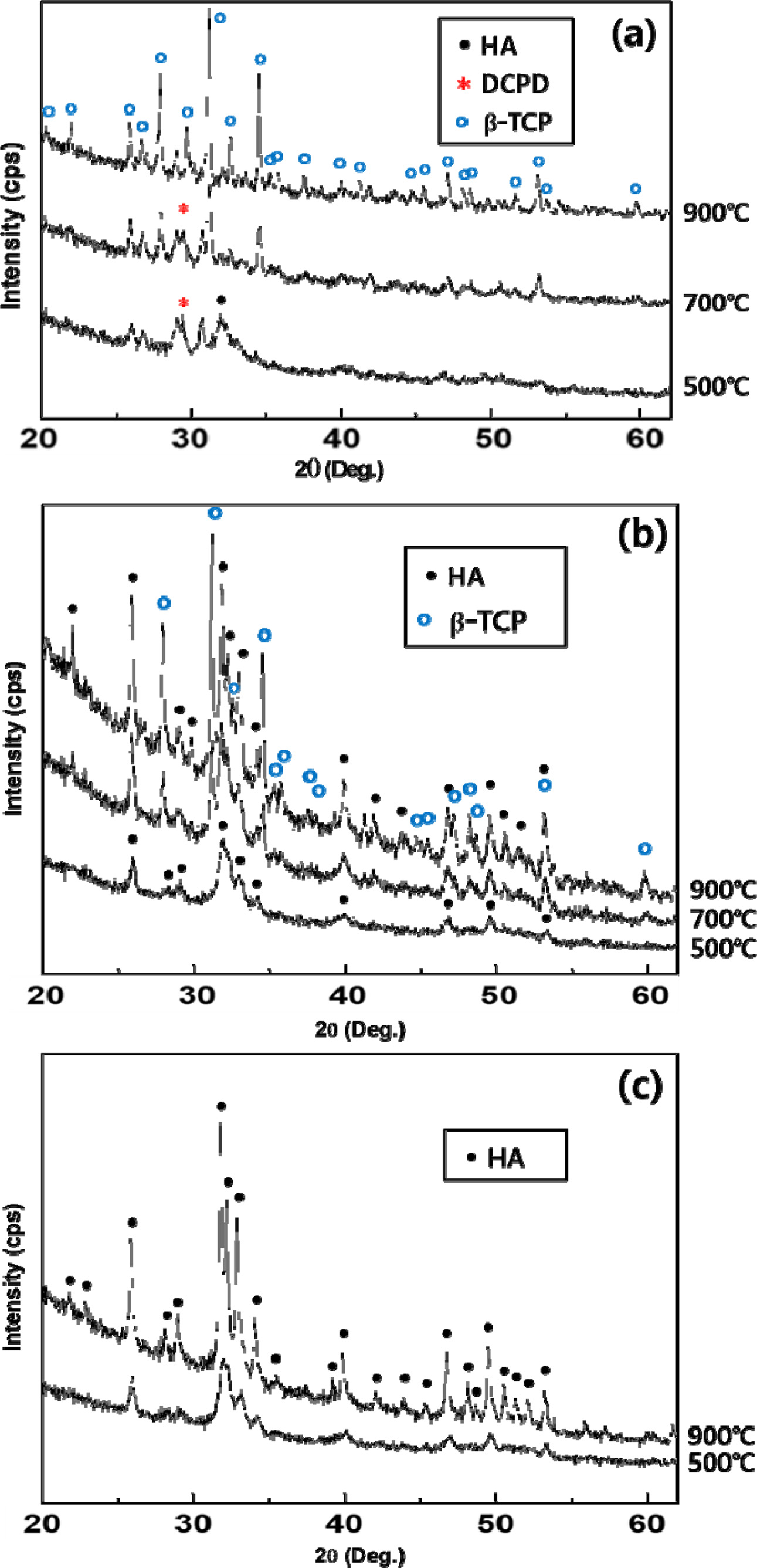

Calcination temperature

plays an important role in the phase formation, as shown

in Fig. 3. In the case of Ca/P =1.30

powder, it showed that phase pure β-TCP was formed by

consuming the pre-existing DCPD and HA as

the calcination temperature increased from 500 oC to 900 oC (Fig. 3(a)). Biphasic

calcium phosphate (β-TCP/HA) and single phase HA can

be obtained from the powders with Ca/P ratios of 1.50 and 1.67, respectively.

Fig. 3(b) shows that in the case of the

powder from Ca/P = 1.50 the TCP phase appears with the pre-existing HA phase after

calcination at 700 oC due to the phase transformation

from amorphous to crystalline β-TCP. The β-TCP

was the dominant phase thereafter. The percentage of volume fraction for β-TCP and HA was

calculated using the relative intensity ratio (RIR) [14]. The HA/β-TCP ratio

was estimated to be 35/65 at 900 oC. For powders from the precursor Ca/P ratio of

1.67, the overall peaks of HA become more distinct with the increasing calcination temperature, and the

narrow peak width suggests increased crystallinity and particulate size (Fig. 3(c)). The particulate size increased from 30 to 50 nm when the calcination

temperature increased from 500 to 900 oC,

respectively. No impurity or secondary phases appeared in this case.

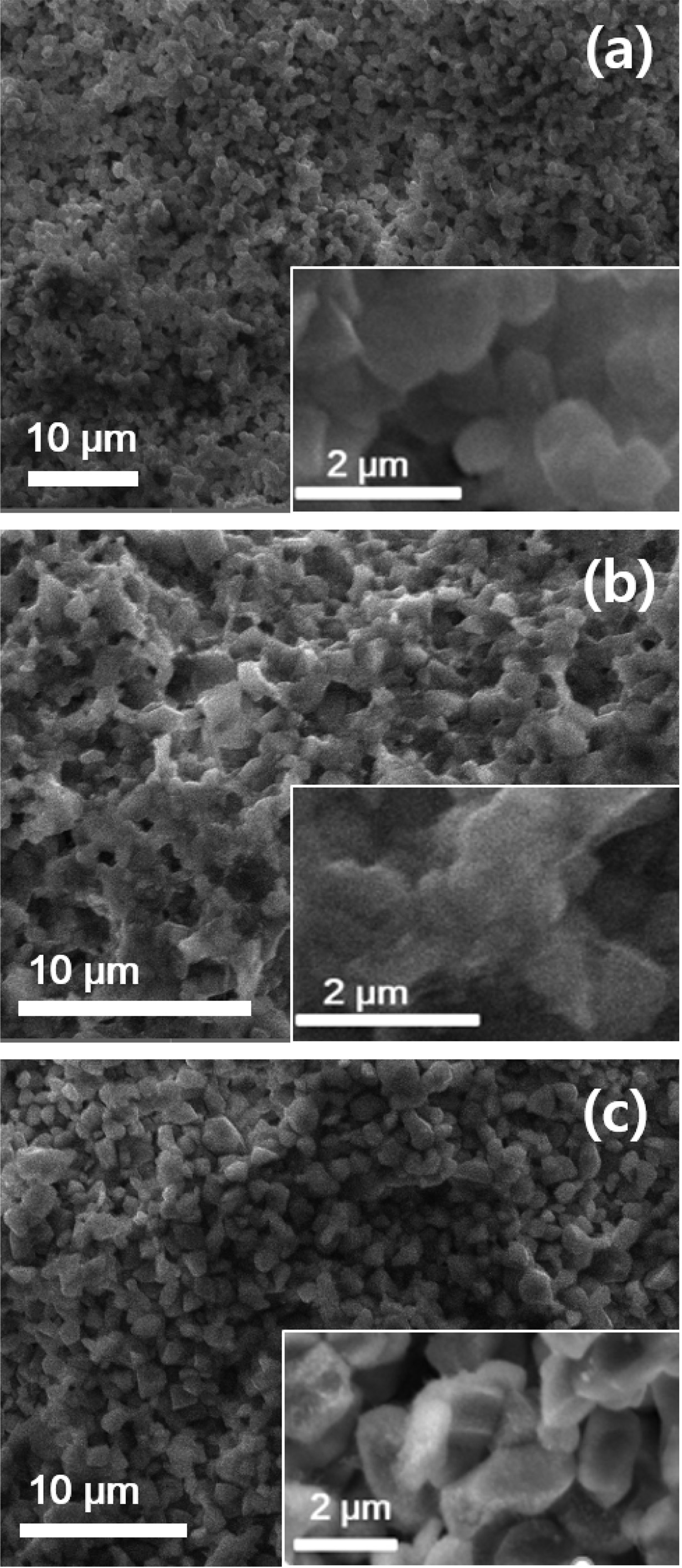

The sinterability of the synthesized powders is

proportional to particle size. The ultra-fine particle size of as-prepared

precipitates leads to higher sinterability. In this study, the diameter of the

green pellets was 12.71 mm. After sintering at 1,100 oC for 2 h, the

diameter has decreased to 9.85 mm (22.5% reduction for HA

from Ca/P=1.67), 9.5 mm (25.3% reduction for β-TCP/HA from Ca/P=1.50) and 10.95

mm (18.5% reduction for β-TCP from Ca/P=1.30). The sintered bodies showed a

certain degree of translucency showing good sinterability (Fig. 4). For pure

HA, it is known that the sintering temperature to achieve such dense ceramics

is 1,250 oC or higher [15, 16]. In particular, low temperature sintering is

essential for β-TCP, because β-TCP reconstructively

transforms into α-TCP above 1,125 oC [17-19].

Ultrafine particles with high reactivity offered high-density ceramic products

at the lower sintering temperature of 1,100 oC. Fig.

5 shows the microstructures of sintered specimens with the precursor

Ca/P ratios of 1.30, 1.50 and 1.67 at 1,100 oC for 2 h. Grains

of around 0.5-1.8 μm in sizes

are observed in the specimens.

In most chemical precipitation processes for calcium

phosphates, the powder properties depend heavily on the processing parameters during

the precipitation reaction due to the slow reaction rate

and the unstable nature of the precursor solution. The morphology, phase, and crystallinity of precipitated

powders were closely

related to precursor concentration,

precursor dropping rate, reaction

pH, and exposure (aging) time in solutions. For example, to prepare single HA phase particles, very slow precursor

dropping rates such as a few drops per minute and a very long aging time over

24 h were essential at low aqueous precursor concentrations of less than 0.6 M

Ca(OH)2 [20, 21].

Furthermore, some wet chemical methods require an extra time-consuming washing step to rinse off by-products and excess reactants. However, in this study, nanometer scale HA, β-TCP, and biphasic β-TCP/HA

powders were conveniently prepared in a fast and simple manner: about 100 times

faster precursor dropping rate at higher precursor concentration without

washing step. Therefore, it can be proposed that the modified process is

economically feasible and capable of mass

production in large quantities.

|

Fig. 1 XRD patterns of synthesized HA powders from Ca/P = 1.67 prepared by (a) heat treatment at different temperatures and (b) ball milling process with various milling time. |

|

Fig. 2 XRD patterns of precipitated calcium phosphates powders from the different precursor Ca/P ratios: (a) Ca/P = 1.30, (b) Ca/P = 1.50, and (c) Ca/P = 1.67. |

|

Fig. 3 XRD patterns of prepared calcium phosphates powders from the different precursor Ca/P ratios ((a) Ca/P = 1.30, (b) Ca/P = 1.50, and (c) Ca/P = 1.67) calcined at different temperatures. |

|

Fig. 4 A translucency example for the sintered specimens at 1,100 oC for 2 h using the prepared calcium phosphates powders from the different precursor Ca/P ratios (TCP (Ca/P = 1.30), TCP/HA (Ca/P = 1.50), and HA (Ca/P = 1.67)). |

|

Fig. 5 SEM micrographs of the sintered ceramics at 1,100 oC for 2 h using the prepared powders from the different precursor Ca/P ratios: (a) TCP (Ca/P = 1.30), (b) β-TCP/HA (Ca/P = 1.50), and (c) HA (Ca/P = 1.67). |

|

Table 1 pH values with ball milling time of precipitated calcium phosphates powders with different precursor Ca/P ratios: Ca/P = 1.30, 1.50, and 1.67. |

The modified approach of the aqueous precipitation method followed by the mechanical ball milling process offered a simple, convenient and economical

route to synthesize calcium phosphates without the pH

control and ripening time used in most wet precipitation

studies. The ball milling step enhanced the reaction process and

promoted the desirable phase synthesis in a short period of time. The biphasic HA/β-TCP composite and pure HA and β-TCP

powders were synthesized according to the initial Ca/P ratio and heat treatment. It was shown that, as the heat treatment temperature increased, the phase pure β-TCP was formed by consuming the pre-existing DCPD and HA in the case of Ca/P = 1.30 powder. For Ca/P=1.50 powder, the biphasic HA/β-TCP

was obtained, where the TCP phase appeared on the pre-existing HA phase after heat treatment at 700 oC. Pure

HA phase without any noticeable second phase

can be synthesized without post heat treatment for the

precursor Ca/P ratio of 1.67. Due to the high

reactivity of the nanoparticles prepared via the modified route, highly dense

ceramics with translucency were formed at a relatively low sintering

temperature of 1,100 oC.

This work was supported by the National Research

Foundation of Korea (NRF) grant funded by the Korean government (Ministry of

Science and ICT) (No. 2017M2B2A9073125).

- 1. N. Eliaz and N. Metoki, Mater. 10 (2017) 334-407.

-

- 2. W. Habraken, P. Habibovic, M. Epple, and M. Bohner, Mater. Today 19 (2016) 69-87.

-

- 3. A. Dudek and L. Adamczyk, Optica Aplicata. 13 (2013) 143-151.

-

- 4. C. Wu and Y. Xiao, Bone Tissue Regen. Insights 2 (2009) 25-29.

-

- 5. J. Marchi, P. Greil, J.C. Bressiani, A. Bressiani, and F. Muller, Appl. Ceram. Technol. 6 (2009) 60-71.

-

- 6. S. Kannan and J.M.F. Ferreira, Chem. Mater. 18 (2006) 198-203.

-

- 7. E.C. Victoria and F.D. Gnanam, Trends Biomater. Artif. Organs 16 (2002) 12-14.

- 8. J. Marchi, P. Greil, J.C. Bressiani, A. Bressiani, and F. Muller, Int. J. Appl. Ceram. Technol. 6 (2009) 60-71.

-

- 9. L. Sun, L.C. Chow, S.A. Frukhtbeyn, and J.E. Bonevich, J. Res. Natl. Inst. Stand. Technol. 115 (2010) 243-255.

-

- 10. K. Salma, L. Berzina-Cimdina, and N. Borodajenko, Process. Appl. Ceram. 4 (2010) 45-51.

-

- 11. O. Mekmene, S. Quillard, T. Rouillon, J.M. Bouler, M. Piot, and F. Gaucheron, Dairy Sci. Technol. 89 (2009) 301-316.

-

- 12. A.K. Nayak, Inter. J. Chem. Tech. Res. 2 (2010) 903-907.

- 13. D.S. Gouveia, A.H.A. Bressiani, and J.C. Bressiani, Mater. Sci. Forum 530-531(2006) 593-598.

-

- 14. M. Ebrahimi and M. Botelho, Data in Brief 10 (2017) 93-97.

-

- 15. S. Ramesh, K.L. Aw, R. Tolouei, M. Amiriyan, C.Y. Tan, M. Hamdi, J. Purbolaksono, A. Hassan, and W.D. Teng, Ceram. Int. 39 (2013) 111-119.

-

- 16. S. Ramesh, C.J. Gan, L.T. Bang, A. Niakan, C.Y. Tan, J. Purbolaksono, H. Chandran, S. Ramesh, B.K. Yap, and W.D. Teng, J. Ceram. Proc. Res. 16 (2015) 686-689.

- 17. J.H. Welch and J.H. Gutt, J. Chem. Soc. 29 (1961) 4442–4444.

-

- 18. D.M.B. Wolff, E.G. Ramalho1, and W. Acchar, Mater, Sci. Forum 530-531 (2006) 581-586.

-

- 19. R.G. Carrodeguas and S.De Aza, Acta Biomater. 7 (2011) 3536-3546.

-

- 20. M. Sokolova, I. Kreicbergs, V. Zalite, and L. Berzina-Cimdinaa, Eurasia Conference on Chemical Sciences Proc. (2012) 1-1.

- 21. L.T. Bang and R. Othman, Ceram. Silikaty 58 (2014) 157-164.

This Article

This Article

-

2019; 20(6): 655-659

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.655

- Received on Jun 7, 2019

- Revised on Sep 16, 2019

- Accepted on Sep 26, 2019

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Byeong Woo Lee

-

Dept. of Ocean Advanced Materials Convergence Engineering, Korea Maritime and Ocean University, Busan 49112, Korea

Tel : +82-51-410-4356 Fax: +82-51-404-3986 - E-mail: bwlee@kmou.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.