- Study on NOx reduction capacity of catalytic coated cordierite monolith

Rekha Durairaja,*, Neelakrishnan Subramanyana and Divakar Duraiswamyb

aDepartment of Automobile Engineering, PSG College of Technology, Coimbatore, TN 641004, India

bDepartment of Chemistry, PSG College of Technology, Coimbatore, TN 641004, India

Legislation world-wide imposes

stringent emission norms, particularly EURO V and beyond. In this regard,

extensive research is being conducted for improving the existing filter design,

material properties and developing alternative design, materials, testing

procedures for more sensitive to reduce NOX values. Cordierite

ceramics are

having good chemical and electrical properties like high

thermal resistance,

low dielectric

constant, low thermal expansion coefficient, and high chemical and mechanical

stability, which makes it for many industrial applications like manufacturing

of the thermal insulation materials, optoelectronic devices, plasma display

panels, solar panels, catalytic convertors etc. In this work, a pair of

cordierite monolith with catalyst coating to NOx storage and

reduction was developed. The effectiveness of the catalysis was verified with

engine exhaust gas analyser. The testing was carried out with diesel as fuel in

a Kirloskar engine with Non-filter, NSR, and combined NSR-SCR system. The

investigation was done for five trials with different emission parameters and

analysed.

Keywords: Catalytic Converter, NOx Storage and Reduction, Compression ratio

Vehicle outflow causes prompt and long haul impacts on

nature. Vehicle depletes produce a wide scope of gases and strong issue,

causing an unnatural weather change, corrosive downpour, and hurting the earth

and human wellbeing. NOx is the term used to indicate the vaporous

blend of nitrogen oxide and nitrogen dioxide in

different structures. NOx

is for the most part shaped at high temperature and weight when nitrogen and

oxygen are joined because of the ignition of fuel. Among the six significant

air contaminations (carbon monoxide, lead, NOx, sulfur dioxide, PM

and VOC's) NOx is viewed as the most dangerous. NOx is a

fundamental element for the arrangement of surface ozone, a contamination that

isn't promptly evaluated close

to the surface with information from current space-based

instruments [1]. Nitrogen oxides (NOx) outflows from

stationary and portable sources are not kidding

dangers to nature since they can cause corrosive downpour,

photochemical exhaust cloud, a dangerous atmospheric devotion and organic

transformation [2]. The NOx stockpiling and decrease (NSR)

methodology is one of the choices for NOx expulsion from diesel

depletes, which works under cyclic oxidizing and diminishing conditions. More

often than not, NSR impetuses for the most part contain respectable metals (for

example Pd, Pt, and Rh) [3]. Commonplace NSR impetuses comprise of a high

surface zone support (for example c-Al2O3,

TiO2, ZrO2, or TiO2-ZrO2) [4]. A

NSR impetus incorporates an essential oxide that chemisorbs NOx

under typical running conditions, and intermittently, a reductant is sustained to the

fumes that desorbs and decreases the put away NOx [5].

NSR is done in the lean NOx trap (LNT), which is worked by cycling

between fuel-lean and fuel-rich conditions. NOx is put away under lean conditions as nitrates and nitrites on salt metal or

antacid earth metal parts [6]. During the lean time frame (term of

~minutes), NOx is caught on the Ba stage

as Ba (NO3)2 and Ba (NO2)2,

predominantly through oxidation of NO to NO2, and on

CeO2 at low temperature (<250 °C). During the rich time

frame (span of ~seconds) reductants from fragmented fuel burning items (H2,

CO, HC) are brought into the fumes stream [7].

Specific impetus decreases selective catalytic reduction

(SCR) framework is at present the best decision to dispense with NOx

discharges from diesel engines. The SCR of NOx has been in wide use

for decades particularly in stationary applications like gas turbines, Boilers,

power plants etc.The SCR consist of monolith similar to that of NSR but the

catalyst used over monolith is a zeolite powder which may be naturally

occurring or synthesized. The reducing agent used is urea/ammonia to convert

NOX into nitrogen (N2) and water vapour (H2O). NOx

emanations in the fumes gas can be wiped out with reductants in

the SCR framework. Smelling salts (NH3) is the most

usually utilized reductants and has high transformation productivity in SCR of

NOx [8]. Particular synergist decrease of NOx by

(urea/SCR) is the most proficient innovation for the after treatment of NOx

from diesel engine fumes to meet stringent emanation guidelines, including EURO

VI and SULEV. For this, the SCR impetus is required to be dynamic,

especially in the low temperature systems, since the

typical fumes gas temperature from a diesel engine going from

100 - 250 °C for light obligation to 200 - 350 °C

for hard core diesel engines is fundamentally lower than

that from a gas engine, and the fumes temperature from a propelled diesel

engine for high eco-friendliness is predictable to turn out to be even lower

[9]. Iron oxide is a commonplace dynamic fixing or advertiser in NH3-SCR

impetuses, which shows great NH3-SCR movement and

N2 selectivity, on account of its

inalienably naturally neighbourly character, its unmistakable warm strength and

its remarkable H2O/SO2 obstruction [10]. LNT and SCR

zoning in double layer impetus improved NOX decrease productivity

and introduced the possibility to diminish the costly platinum

gathering metals (PGM) stacking by up to 40% from that of LNT impetus without

debasing its de-NOx execution under mimicked diesel fumes

conditions [11]. Temperature based model methodology was performed

by [12] to advance SCR adjustment for BSIV standards utilizing the alignment

procedure. The structure of the SCR framework included impetus

choice, complex controller advancement like urea dosing

procedure and the communication between engine arrangement and after treatment

framework. A few looks into were done in the past on NOx stockpiling

and decrease (NSR) [13] and specific impetus decrease (SCR) exclusively to

diminish NOx discharge in car diesel engines. The examination

includes the advancement and testing of an exhaust system with a joined NSR-SCR

impetus for diesel engine fumes frameworks, for improving the viability of NOx

outflow decrease in diesel engine debilitates with consolidated NSR-SCR

impetus. The exploration proposes an AI calculation to enhance test information

dependent on demonstrating. The presentation of the

created catalyser is contrasted and recreation model and test outcomes. It is

watched the proposed advancement methodology can improve

the NOx decrease and

the effectiveness of the diesel engine fumes frameworks.

Vehicular engines working under lean consume conditions

are ending up progressively prevalent because of their

better efficiency as looked at than regular Otto gas engines. Be that as it

may, the lethal NOx fumes gas parts of lean-consume engines can't be

productively evacuated with three-way impetuses, which are

compelling just under stoichiometric conditions.

Therefore, particular reactant decrease (SCR) of NOx

utilizing urea as a reductant has been produced for versatile lean NOx

evacuation Zhang et al. [14], Alcalde-Santiago et al. [15] portrayed

an idea comprising of a macroporous bearer free impetus.

An alternate Cu-containing Sr-Ti NSR impetus with

a macroporous system was integrated, and its greatest NOx

stockpiling limit (1,500 μmol NOx/g catalyst) essentially

outperformed that of traditional Pt/Ba/Al2O3 details

(~600 - 800 μmol NOx/g catalyst). Diesel engines

can possibly agree to the much progressively stringent CO2

emanations enactment, which will be applied in the main vehicle markets

worldwide in the coming years. E. Srinivasa Rao et al. [16] discussed about the

solid state method which was adopted to prepare Cordierite

ceramics of different particle sizes. Cordierite ceramic’s

particle size during the sintering process influence whether that material is

suitable for kiln- furniture application. Lafossas et al. [17] displayed a

response model for oxygen stockpiling which impacts the

accessibility of diminishing specialists' for desulfation.

Krishnan et al. [18] displayed a technique to build the engine

torque by expanding the comparability proportion and at the

same time controlling the NOx discharges by embracing a mix of EGR

and H2-SCR. The cold EGR methodology was received, where the

re-coursed fumes gas was cooled to a specific temperature. Kwang-Ho Lee [19]

was discussed mechanical properties and wear characteristics

of yttria-stabilized ZrO2 monoliths ceramic. Yuan et al.

[20] clarified a NH3 slip control for diesel engine

specific synergist decrease after-treatment frame- work. The NH3 slip

control execution of the proposed technique was tentatively approved in the

European transient cycle. Han et al. [21] built up a control

situated lean NOx trap (LNT) model for the LNT recovery

reason to gauge the NOx stockpiling portion, NOx focus

out of a LNT impetus and a LNT impetus bed temperature.

Park et al. [22] displayed the mechanical properties and

crystallization of ceramic cores depends on the silica particle

morphology, it also influences the mixing, flow, and

sintering behaviour of feedstock. (Hydrocarbon-specific reactant decrease

(HC-SCR) is a de-NOx framework for diesel engines, which

uses locally available fuel as the reductants to improve

the framework. Gu et al. [23] examined the impacts of including hydrogen the

proficiency of NOx decrease by means of HC-SCR utilizing

different reductants. Cheng et al. [24] introduced another

impetus for NO decrease from BEA zeolites saturated with various metals

bolstered by the particle trading technique. Cu-BEA indicated high synergist

movement for NO decrease by CO and H2 at 300 - 500 °C,

while Co-BEA demonstrated the high reactant action of NO

decrease by CH4 at 400 - 500 °C. Resitoglu et al. [25] decided the NOx

transformation effectiveness of ethanol-biodiesel blends in the particular

reactant decrease framework at various engine burdens and distinctive

fumes gas temperatures under genuine working

conditions. It was discovered that the reductants with 15% biodiesel and 85%

ethanol, had the most elevated transformation execution. De-La-Torre

et al. [26] arranged and tried for NOx expulsion from diesel

and lean consume engines fumes gases by coupling NSR-SCR frameworks containing

a Pt-BaO/Al2O3 NSR stone monument and

Cu/CHA, Cu/ZSM-5 (or) Cu/BETA SCR impetuses. In

past investigations, different enhancements were

performed independently on both NSR and SCR in diesel

engine fumes frameworks. Enrique Rocha-Rangel [27]

discussed about the preliminary characterization of the microstructure and its

composition features subsequent

to the cycle of in-situ process. The dense, fine and homogeneous microstructure

of Al2O3 based composite materials

with reinforcement particles of TixAly was discussed.

Enhancement of joined NSR-SCR impetus is a novel idea proposed in this

exploration to improve the NOx decrease and to create powerful

exhaust systems the diesel engine fumes frameworks. In this way, the proposed

methodology lessens NOx emanation with ease and takes out the

smelling salts slip and spares space required for dynamic measurement control

in diesel engines of autos separately.

An extended diesel engine populace has weight on controlling

diesel usage and NOx discharges. The fundamental headway in diesel

outflow control was cultivated through engine developments, fusing

changes in the start chamber arrangement, improved fuel

struc- tures, charge air cooling,

and uncommon thought with respect to lube oil usage. With the growing

enthusiasm for a cleaner circumstance and better air quality, a diesel engine

creator is constrained to satisfy stricter guidelines for gases release of an

engine. Improved data of the likelihood to diminish these sorts of releases

could help engine fashioners to modify their engines with

successful outpouring control frameworks. Despite the

fact that, by far most of the writing required exhibits a slight

augmentation in NOx outpourings when using a differing synergist

channel. The fundamental objective of this work is to furnish a capable fumes

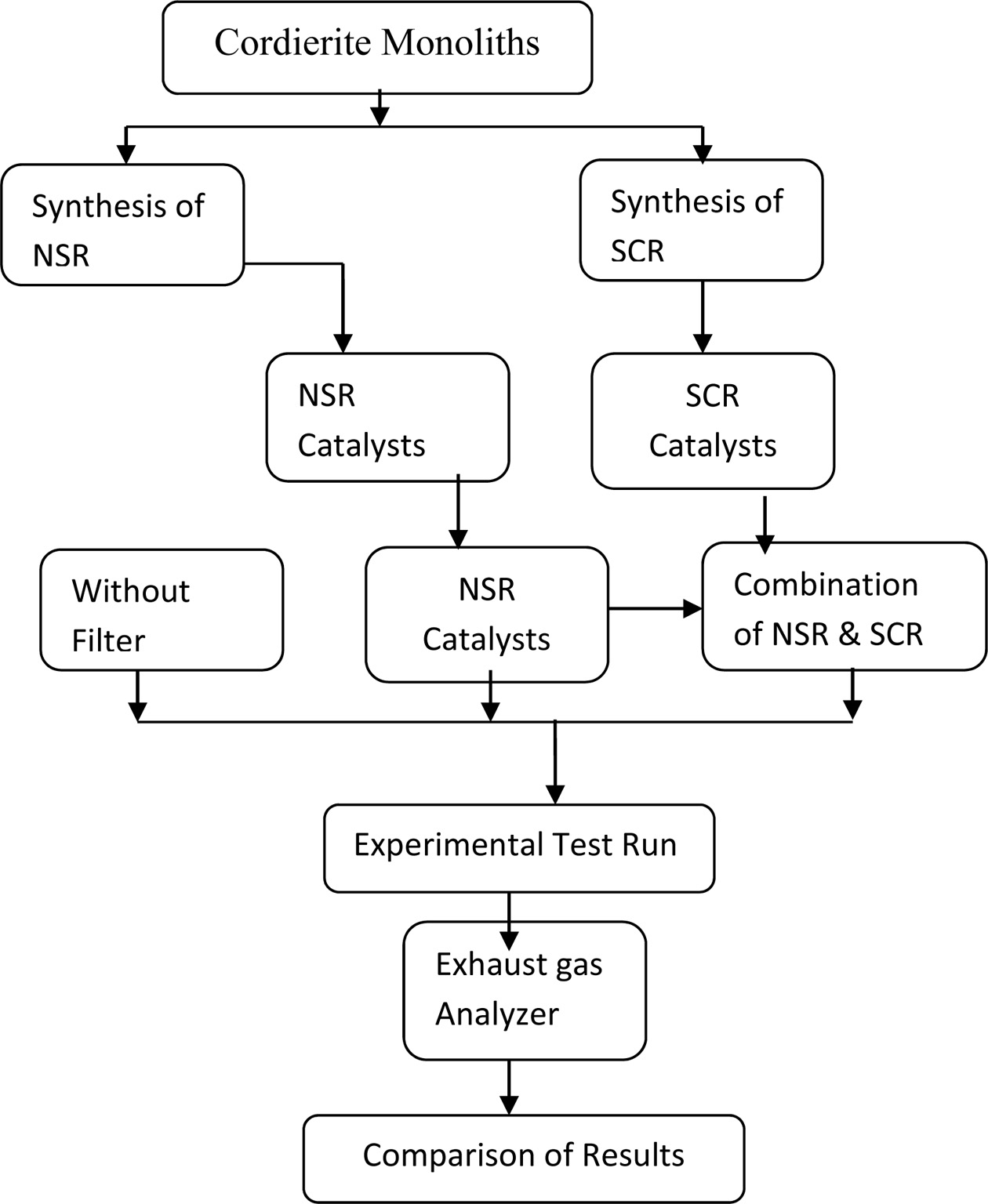

framework with a mix of NSR and SCR technique. The process flow

chart of this work shown in Fig. 1. The diesel engine exhaust

emission has been tested without any filtration aids, with NSR filter and with

NSR and SCR filter along with the preparation of NSR and SCR catalysts.

Finally, the filter capability towards NOx decline is assessed with

different compression ratios and loading conditions.

|

Fig. 1 Process flow chart. |

More toxic substances are there in diesel engine exhaust

emission. Catalytic converters play an important role to minimize such harmful

gases into harmless gases. In this research paper, the synthesis of NSR and SCR

catalysts are explained along with experimental test results.

Materials

and methods used for experimentation

In this experimental research, the cordierite monolith has

been synthesized with suitable catalyst to obtain required NSR

and SCR catalytic converter. A single cylinder diesel engine has been tested

without filter, along with NSR converter, Combination of NSR and SCR

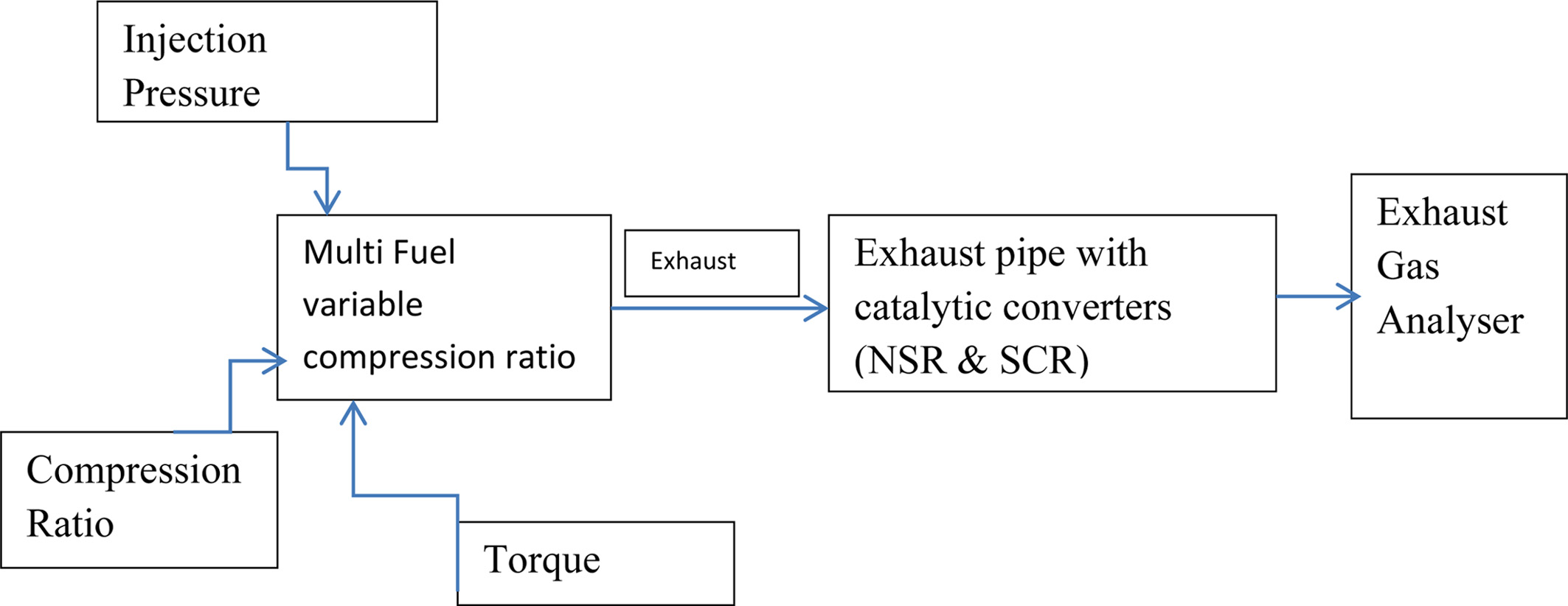

converters. Figure 2 shows the schematic representation

of experimental setup.

Catalytic

converter

In the diesel engine exhaust gas, the harmful gases like

carbon monoxide and unburned hydrocarbon concentrations are more, the catalytic

converters present in the exhaust pipe has oxidized the carbon monoxide,

hydrocarbon emissions into harmless carbon dioxide and water vapour. This was

because of the chemical response of the catalytic converter [28].

Diesel

engine

In this experimentation, single cylinder variable

compression ratio diesel engine was utilized for the testing of catalytic

converters. Diesel is more and more efficient, they should utilize less fuel,

produce less carbon dioxide (CO2) emissions, and contribute less to

global warming [29]

|

Fig. 2 Schematic setup of experimental setup. |

Engine - Single Cylinder Four stroke variable

compression ratio, water cooled

Diesel engine

HP/kW : 5/3.7

RPM : 1500

Bore Diameter : 87.5

mm

Stroke : 110 mm

Compression

Ratio : 17.5

to 20

Injection

pressure : 80-230 bar

Torque : 0-20 Nm

The engine specifications of the Kirloskar engine utilized

in this experimentation are as given above. The four-stroke diesel engine

coupled with eddy current dynamometer for varying load conditions along with

compression proportion of 17.5:1 to 20:1 is taken for testing purposes [30].

Figure 3, shows the Kirloskar diesel engine along with

loading device of eddy current dynamometer which is used for experimentation. A

piezoelectric transducer part, sensors are associated with the

engine cylinder and crank angle sensor and charge amplifier for

obtaining resolution 1 degree and 5,000 rpm with TDC marker pulse

is mounted to the flywheel and for gaining signals for engine

indication. To measure the percentage of CO, HC, CO2, O2,

and NOx (ppm) emissions the AVL gas analyser has been utilized.

|

Fig. 3 Kirloskar Diesel Engine. |

General

aspects of the NSR (NOx Storage and Reduction) catalysis

NOx storage and reduction is considered as one

of the most promising technology for NOx removal from diesel engine exhausts

gases. It can also be mentioned as Lean NOx Traps (LNT). Recent

excellent reviews can be found in the literature on this technology.

Working:

The NSR catalysts run cyclically under lean environ- ment

(oxidizing) and rich environment (reducing), being defined by

the corresponding Air/Fuel ratios. While running on the road, lean and rich

conditions have to be used in an alternative way. Under lean conditions, with

excess of oxygen i.e.; high (Air/Fuel), NOx are adsorbed (alkaline

or earth-alkaline compounds) by the catalyst, and later under rich conditions

(Air/Fuel < 14.63) the stored NOx are released and reduced. Most

studies in the literature have used storage material as Barium, reduction

material as H-Zeolite.

NSR Mechanism

NSR mechanism can be explained by the five following

steps:

(a) Oxidation of NO to NO2 (lean

conditions, oxidizing environment).

(b) Adsorption of NOx as

nitrites/nitrates on the storage sites (lean period, oxidizing environment).

(c) Injection and evolution of the used reducing

agent (H2, CO or HC).

(d) Release of the stored NOx from the

catalyst surface to the gas stream (rich period, reducing environment).

(e) Reduction of NOx to N2

(rich period, reducing environment).

Procedure for the preparation of catalyst

The procedure for the preparation of NSR catalyst was

detailed below

Wash coat preparation:

This

section focused on the preparation procedure

of monolithic NSR catalyst. In real application, the mechanical properties of

the catalyst temperature and vibrational

strengths may vary due to exhaust gases. Due to high thermal stability and low

expansion coefficient, the Cordierite

(2MgO.2Al2O3.5SiO2), has been chosen as the base material in automotive application.

However, this material exhibits a low

surface area which is not suitable for the subsequent incorporation of the

active phases.

Consequently, the first step of the catalyst preparation

consists of the monolithic substrate wash coating with a high surface area oxide,

usually alumina. The most common wash coating procedure is carried out by

dipping the monolith into slurry, which is usually of alumina. The procedures

are stated below

Step 1:

Calculate the weight of the monolith.

Step 2: Take

100 mL of distilled water and stir using magnetic stirrer.

Step 3: Add

10 g wt.% of γ-Al2O3 and allow it to stir well for 5

min at 450-500 rpm.

Step 4: Add

glacial acetic acid (CH3COOH) gradually and stir

well.

Step 5: Check

the pH level using pH meter. Step 6: Repeat the above step until pH of 2-3 is

obtained.

Step 7: Allow

the solution to stir well for 30 minutes.

Step 8: Dip

the cordierite monolith substrate in the slurry using tongs for 10 seconds.

Step 9: Clear

the pores of the monolith using blower.

Step 10: Dry

it in oven for 20 minutes and allow it to attain room temperature.

Step 11: Again calculate the

weight gained over monolith.

Step 12:

Repeat the steps until required amount of γ-Al2O3 gets

coated over the substrate [31]. It is studied that the threshold value of particle

size around 5 μm which is coincident with the size of the cordierite

macropores; larger alumina particles do not penetrate into the macropores of

the substrate resulting in a poor anchoring of the alumina layer. Therefore,

the smaller the particle size in the slurry, the higher the alumina layer

anchoring [32]. Another characteristic to be controlled is the stabilization of

the alumina slurry so as to avoid the particles from

settling down. It is studied that addition of some acetic acid to

shift pH between 3 and 4 improved the slurry stabilization. Furthermore, the

addition of acetic acid up to 2.5 mol L-1

(pH = 2.6) decreased considerably the viscosity of the slurry, permitting

the use of concentrated Al2O3 slurries without

penalization in the layer homogeneity [31]. Initial weight of the

monolith was 16.9538 g. The weight gained by the

monolith after tenth immersion was 3.9360 g. The amount of γ-alumina loaded to

the monolith depends on the volume of the monolith [31].

Platinum incorporation

The next step in the catalyst preparation is the

incor- poration of the active

phases. As already mentioned, NSR catalysts are usually composed of an alkali

or alkali-earth oxide and a noble metal deposited onto the alumina.

The most common metal used for NSR catalyst formulation

is Pt, whereas BaO is normally used as the storage

component. The order of the incorporation steps of the

active phases Pt and Ba is important, especially when operating at higher

temperatures; a higher storage capacity is obtained when impregnating Pt/Al2O3

with Ba than when impregnating Ba/Al2O3

with Pt, increasing the storage value as much as 54% when adding Ba in the

last step. Platinum can be incorporated following two different

procedures, conventional wetness impregnation and

adsorption from solution. In this work adsorption method was followed due good

compromise between platinum dispersion and thermal stabilization of the catalyst

[31]. In the adsorption procedure, the monoliths were

immersed in an aqueous solution with the adequate

concentration of Pt. The monoliths were maintained immersed in the solution for

24 h so as to reach the adsorption equilibrium. Then, the

monoliths were removed from the solution, the excess of

liquid blown out and finally the monoliths were calcined

at 500 °C, respectively.

Barium incorporation:

The last step in the NSR catalyst preparation is the incorporation

of the NOx storage component, i.e. barium. The

precursor used was barium nitrate and two different procedures

were followed: wetness impregnation and incipient wetness impregnation (also

known as dry impregnation).

In this work wetness impregnation method was adapted;

the monolith channels were filled with an aqueous solution containing the

desired amount of barium. Later the monolith was dried and calcined.

The weight gained by the γ-alumina coated monolith after

ninth immersion was 1.742 g as per requirements [31].

General

aspects of the SCR (Selective Catalytic Reduction) catalysis

The selective catalytic reduction of NOx is

widely used decades before, particularly in stationary applications

like gas turbines, Boilers, power plants etc. Now, SCR is being used in heavy

duty diesel vehicles widely in Europe to meet Euro-4 and later emission

standards.

The SCR consist of monolith similar to that of NSR but the

catalyst used over monolith is a zeolite powder which may be naturally

occurring or synthesized. The reducing agent used is urea/ammonia to convert NOx

into nitrogen (N2) and water vapour (H2O).

Working

The selective catalytic reduction system reduces the NOx

with the help of Metal supported catalyst coated over

wash-coated ceramic monolith. In SCR the catalytic action is

based on the amount of NOx coming from the exhaust of the engine. It

is not working in lean and rich condition as like in NSR. The SCR

consists of monolith coated with metal supported zeolite

catalyst and ammonia tank in which the urea contains 32.5% of ammonia

with de-ionized water.

NO + NO2 + 2NH3 → 2N2

+ 3H2O

SCR Mechanism

a. Dynamic dosage injection of urea based on the NOx

ppm value from the exhaust gas.

b. Reducing the NOx with the

help of NH3 stored inside the zeolite and converts it

into nitrogen and water.

4NH3 + 4NO + O2 → 4N2 +

6H2O

4NH3 + 2NO + 2NO2 → 4N2 +

6H2O

4NH3 + 5O2 → 4NO + 6H2

Catalyst preparation

The catalyst preparation method for ZSM5 & H-Beta SCR

catalyst is same. The H-Beta zeolite is mixed with the copper nitrate with

de-ionized air at 60 oC, for 24 hours for ion exchange. If the

Zeolite is in its NH4-

zeolite form then it is to be calcined at 500 oC, for 4 h [31].

For uniform dispersion of catalyst over the monolith and for

better catalytic action the monolith powder has to be in nano size. For

reducing the size of metal powders the method used is ball milling. The calcined

Cu-Zeolite is mixed with 20% colloidal silica and coated

over the monolith by dip coating. The process is continued

until the monolith had been coated with the required amount of weight

percentage of the Cu-Zeolite catalyst. The following steps were to be carried

out during dip coating for uniform coating of catalyst.

Step 1: The monolith is dipped inside the solution which

was stirred by ultrasonic bath for better particle dispersion.

Step 2: Later water is removed by blowing air using an air

blower inside the monolith.

Step 3: The monolith is now heated inside a furnace at

100 oC for about 15 min to remove the water and make it dry.

Step 4: Once the monolith was dried, it is cooled to room

temperature through natural cooling and weighed to determine the weight gained

for individual iteration.

In this work after fifteenth immersion the weight gained

by the monolith was 1.24 g as the requirement [31].

When the required weight percentage of catalyst has been

loaded over the monolith it is calcined for about 4 hours at

550 oC, for catalyst stabilization on the monolith

and to remove the volatile fractions.

In this research, the proposed design of catalytic

convertor to accommodate both NSR and SCR catalyst has been developed based on

the size of prototype monolith.

Design Constraints:![]() Monolith

size.

Monolith

size.![]() Exhaust

outlet diameter

Exhaust

outlet diameter![]() Flow rate of

gas for the prototype.

Flow rate of

gas for the prototype.![]() Temperature

of exhaust gas.

Temperature

of exhaust gas.![]() Flow

distribution.

Flow

distribution.![]() Catalyst

coating (Wt. %).

Catalyst

coating (Wt. %).

The two catalytic converters NSR and SCR are utilized

for converting dangerous exhaust gases into harmless gases. In order to measure

the required parameters like emission levels and temperatures vent out lets and

thermocouples has provided at the start, in between NSR and SCR catalysts and

at the end. This output taken to the analyser for measurement.

Exhaust

outlet diameter

The exhaust outlet diameter decides the velocity of the

exhaust gas from the engine and it is measured as 1̋ using Vernier calliper.

Flow

rate of gas

The flow rate decides the monolith size to be incor- porated. Monolith is used for the

complete conversion of the exhaust emission. But here, as the monolith size is

constant, the flow rate has been adjusted with respect to the monolith size.

The flow rate of exhaust gas can be calculated theoretically as well as

practically. The practical flow rate can be calculated using an anemom- eter which measures the velocity of

the exhaust gas. Flow rate is the product of exhaust gas velocity and cross

sectional area.

Temperature

of exhaust gas and catalytic converter

The temperature of the exhaust gas decides the conversion

rate of the catalytic converter and the conversion efficiency. Since the

catalytic action is more at elevated temperatures [33], the temperature of the

catalytic converter should be maintained 250 ºC from the beginning in

order to achieve catalytic action at all conditions.

Flow

distribution

Flow distribution refers to the distribution of exhaust

gas throughout the monolith coated with the catalyst for maximum contact of the

exhaust gas with the catalyst. This flow distribution is based on the inlet and

outlet cone angle and at the same time larger cone angles

results in vortex inside the monolith which create

backpressure. So cone angle 45º has been selected.

Thickness

of catalyst

Coating of catalyst over the monolith is based on weight

percentage of monolith’s total weight [31]. If the coating percentage is higher

than the standard value, then the catalyst will block the pores of the

monolith, which will result in high back pressure as well as reduced catalytic

action.

Fabricated

prototype

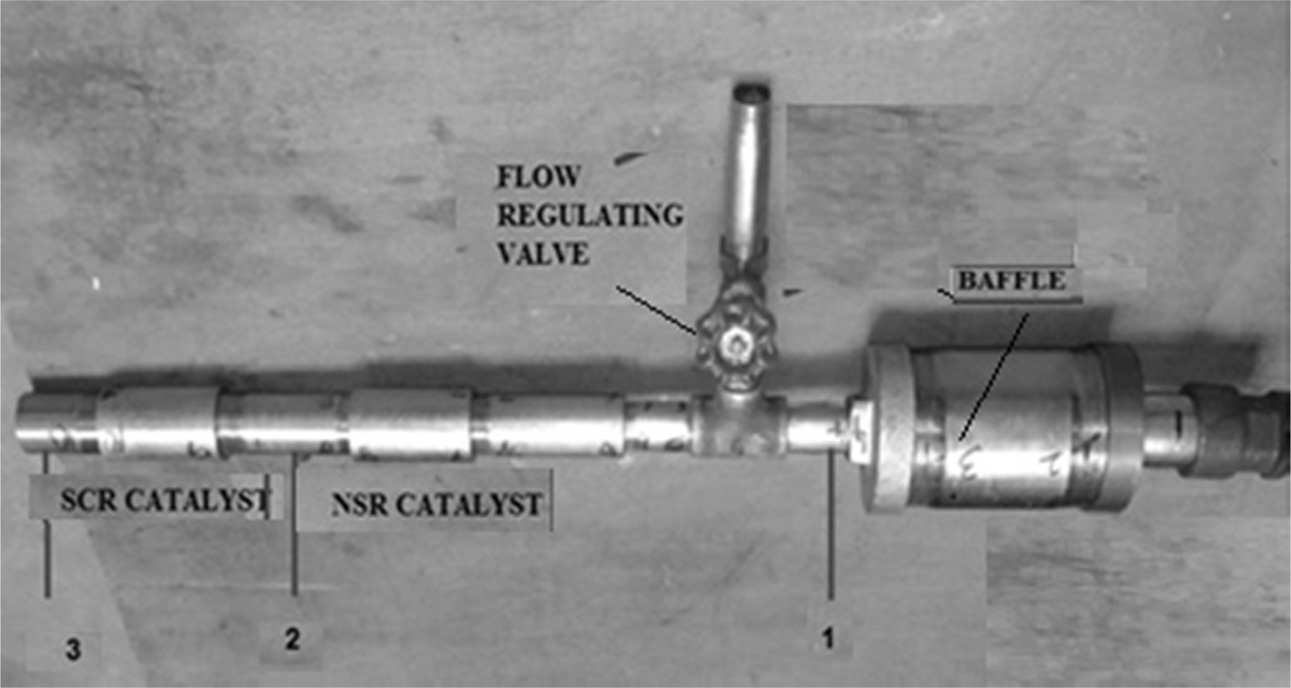

Figure 4 shows the fabricated proto type exhaust pipe to

accommodate the NSR and SCR catalysts. Baffle is located before the location of

the catalysts to direct the flow of exhaust gases. Flow regulating valve also

provided to regulate the quantum of exhaust gas to be entered into the

catalysts section.

|

Fig. 4 Fabricated Exhaust pipe for the placement of NSR and SCR catalysts. |

The testing was done by using diesel as fuel on a

Kirloskar engine that was at 1,500 rpm constant speed engine. The fabricated

proto type exhaust pipe was fitted to the diesel engine fumes with a T-joint.

The testing was completed by applying different load and compression ratio to

find the efficiency of catalytic converters. An eddy current dynamometer [34]

was utilized to load the engine at 0, 50% N-m, and 100% N-m loading conditions.

The testing was done under different laboratory conditions, for example,

shifting temperature and stream rate of exhaust gases. In the running

conditions, diverse info parameters like fuel consumption, indicated power

thermal efficiency etc. also noted at different conditions. The experiment was

conducted at different torques in N-m like 0, 10, 20, and compression ratios

like 17.5, 18.75 and 20. The testing was completed without filter,

with NSR converter, and with NSR-SCR converters. The exhaust emission

gases coming out of the exhaust pipe after catalytic reaction were associated

with the gas analyser and sensors to recognize the percentage

of each gas emitted. The emission performance also tested with the

engine in real-time conditions with the assistance of expert combustion

monitoring systems [35].

In this experimentation, the exhaust gases from a diesel

engine are examined and are classified. For varies compression

ratio (CR), and Torque (L) of the diesel engine, the experimentations are done

without the utilization of filter, with NSR converter, and with NSR and SCR

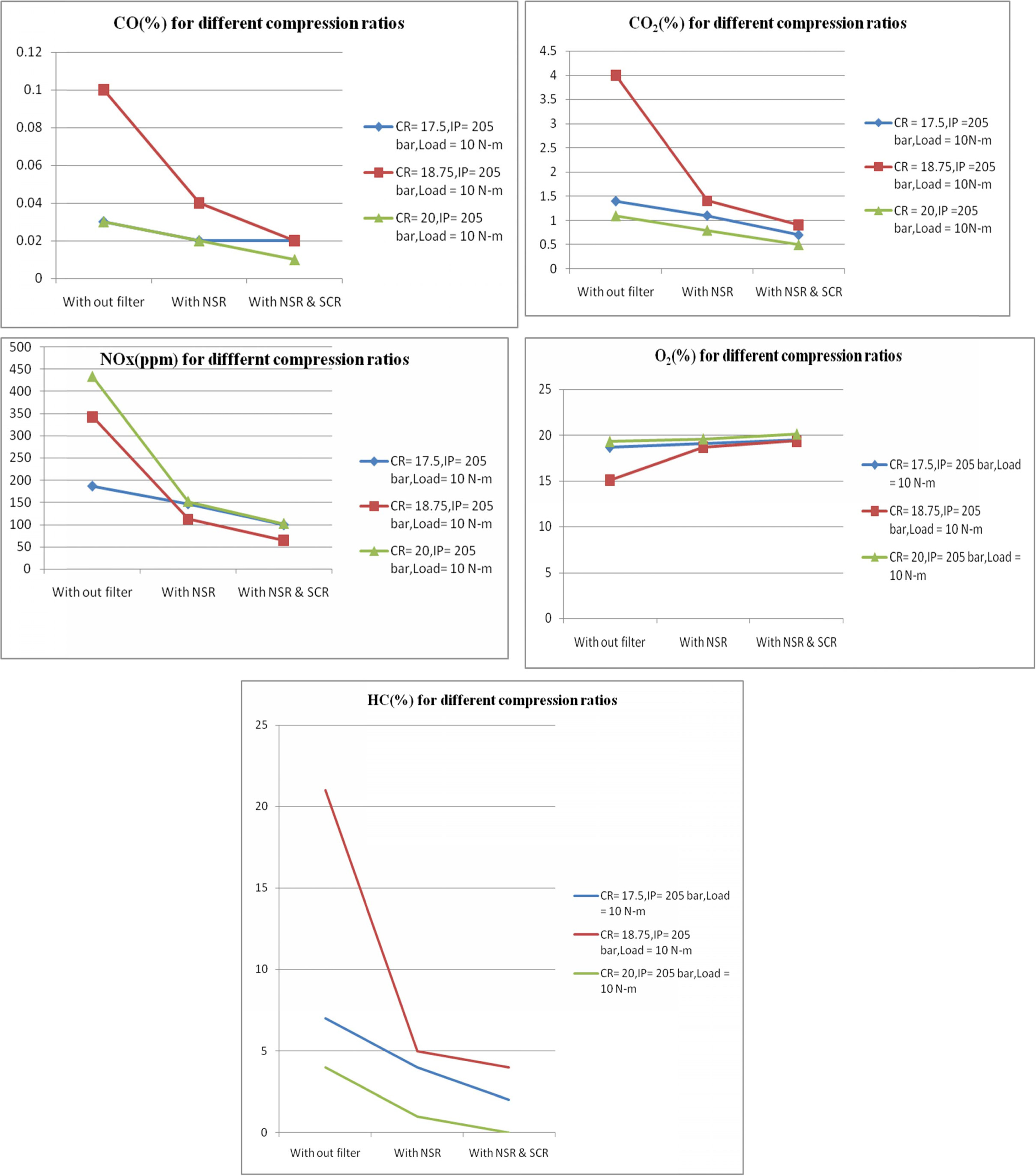

converters. Figure 5, shows the CO, CO2, NOX, O2 and

HC emission values at different output conditions like without

filter, with NSR and with NSR and SCR filters at compression ratios

of 17.5, 18.75 and 20 respectively. When the compression ratio

increases from 17.5 to 20, then the inside pressure of the cylinder increases,

thereby increasing the level of combustion process. This results in increased

CO2 emission and lower CO emission. The NSR and SCR filters also

help to reduce the CO emission up to 200% at higher compression ratios. It is

also observed that the NOx emission increased owing to the higher

pressure inside the cylinder due to high compression ratio. This leads to

increase of heat release rate. The high temperature and pressure

inside the cylinder agitates NOx emissions. Even

though NOx emission was high at high compression

ratio, the percentage of increase of NOx without filter was

132% but after NSR and SCR reaction the percentage of increase

of NOx at high compression ratio was only 20%. This

shows the efficiency of the filters. It is observed that if the

NOx value decreased in the exhaust, it is due to increased O2

emission to the atmosphere. When the compression ratio increases, the flame

propagation is much faster, there by shortening the combustion

process. This increases the charge temperature and reduce the HC

emission to a certain extent. In this work the HC emission is

found to be almost zero at high compression ratios after

NSR and SCR filter reaction process as shown in Fig.

5. However, the CO,CO2 and HC emissions were higher

at compression ratio of 18.75 when com-

pared to compression ratio of 20. Significantly lower O2

emission at this compression ratio indicates that there may be

a chance of incomplete combustion process due to low

cylinder wall temperature, too slow flame speed and in sufficient oxygen

content.

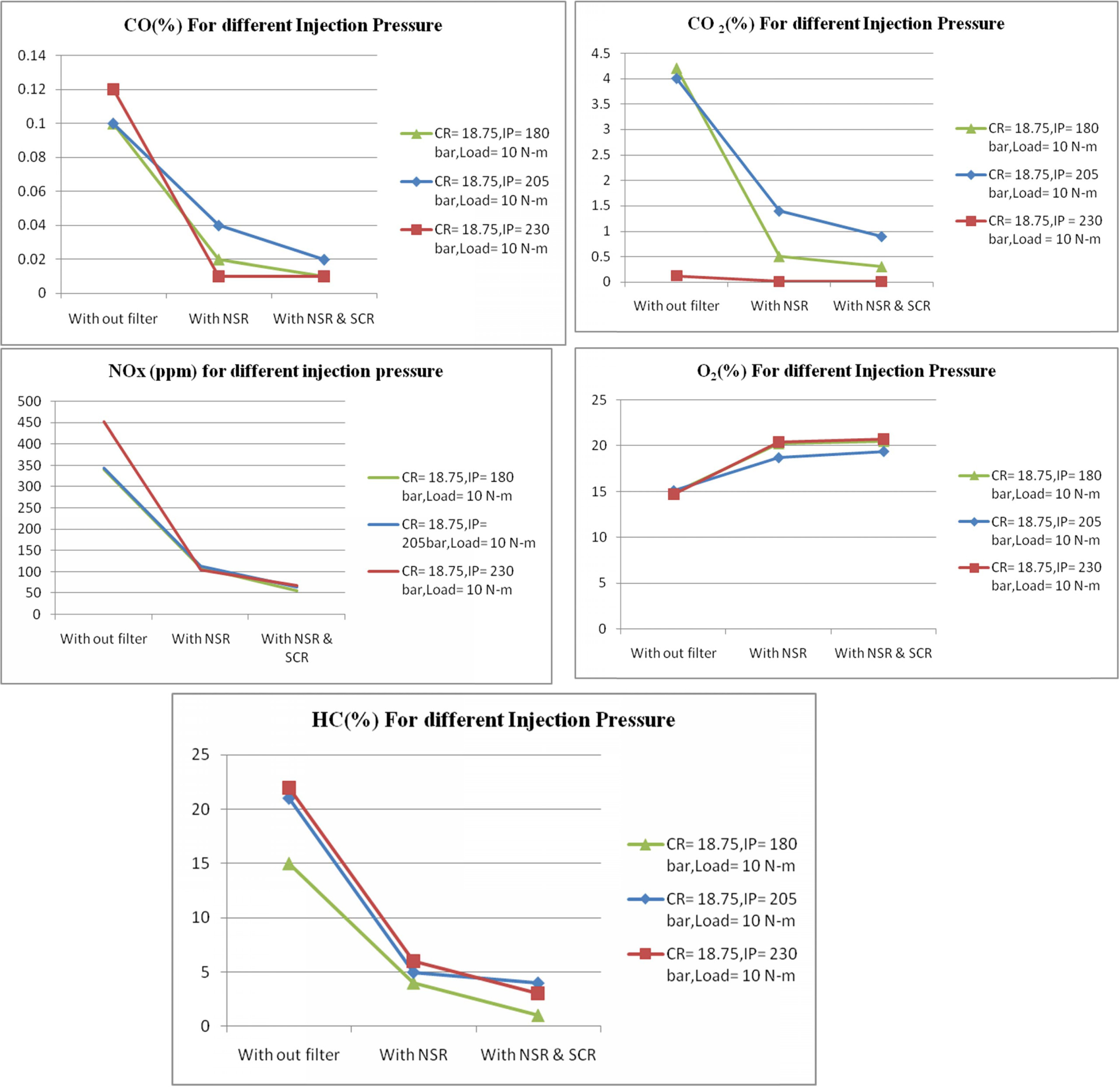

The test was also conducted at different injection

pressures while keeping the compression ratio and load constant.

Spray formation and air-fuel mixing are found to be

influenced by injection pressure. The velocity and momentum of fuel droplets

coming out of the nozzle depends upon the injection pressure.

When the injection pressure is high finer atomization and

better air fuel mixing has been occurring, resulting in high temperature inside

the cylinder. Hence NOx emission increases at high injection

pressure. Figure 6 show the emissions readings at different injection

pressures. It is seen that at 230 bar injection pressure, the NOx

emission reduction is achieved with NSR and SCR filter as 619% compared with no

filter condition. The corresponding CO, CO2 and HC

emissions at various injection pressure are as shown in Fig. 6.

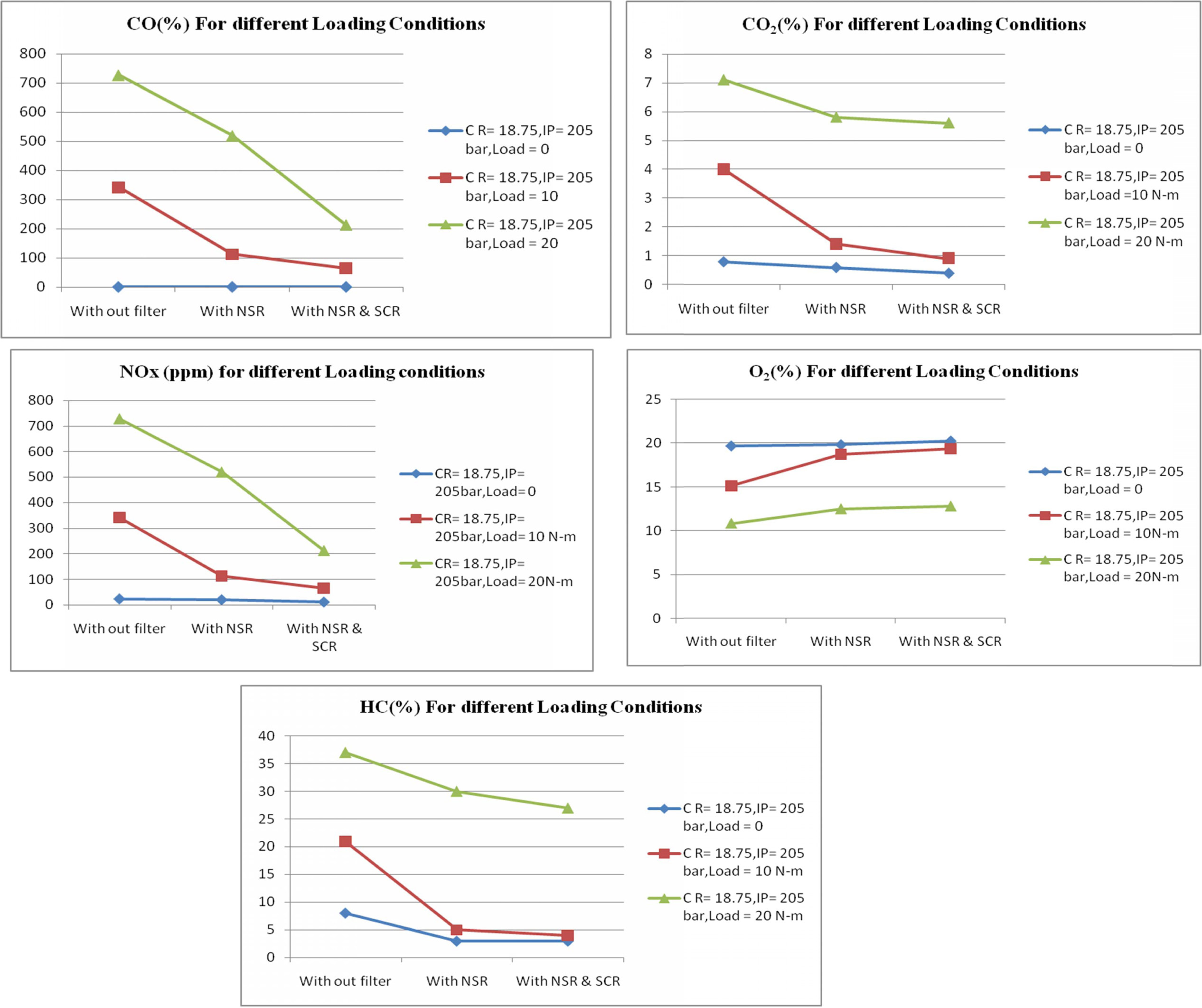

The test was also conducted at different loading

conditions keeping the compression ratio and injection pressure as constant. It

is observed when the load increases the NOx emission also increases

due to high pressure in the air fuel mixture inside the cylinder

Figure 7 show the emission readings at different loading

conditions. At full load condition the NOx emission has been reduced

to 214% when compared with no filter and with NSR and SCR filter.

Proportionately O2 emission also increased noticeably. When the

engine ran at full load condition, the amount of oxygen inside the cylinder was

high but to maintain the constant speed of the engine more fuel is consumed

when compared to no load condition. This may lead to too large diesel droplets

or if insufficient turbulence or swirl is created inside the combustion

chamber, this results in high CO emission at full load condition. But the

percentage of CO emission is found to decreases to 110% while using NSR and SCR

filters compare with no filter at full load conditions. The % HC emission is

compared and shown in Fig. 7.

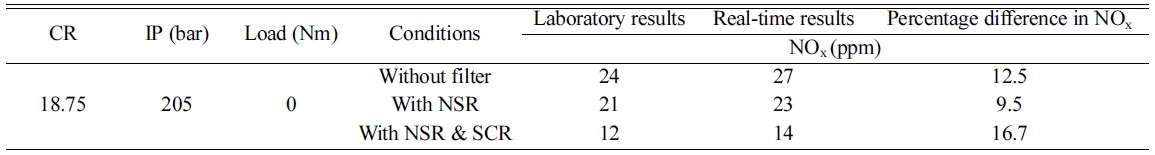

Comparison of performance

between actual and lab experiments (Table 1).

|

Fig. 5 Emission Readings at different compression ratios. |

|

Fig. 6 Emission readings at different injection pressures. |

|

Fig. 7 Emission Readings at different Loading conditions. |

|

Table 1 Percentage difference of performance between actual and lab experiments. |

This examination can be extended in the future by changing

the selective catalytic reduction system to non-selective catalytic reduction

system, which utilized a precious metal-based catalytic converter. These will

help to reduce the NOx, unburned HC, and CO and these can directly

be connected to IC engines with fuel-rich ignition systems respectively.

The authors gratefully acknowledge the support received

from the Department of Automobile Engineering and Department of Chemistry, PSG

College of Technology, Coimbatore for conducting the experiments.

- 1. B. N. Duncan, L. N. Lamsal, A. M. Thompson, Y.Yoshida, Z. Lu, D. G. Streets, M. M. Hurwitz, and K. E. Pickering, J. Geophys. Res. Atmos. 121 (2015) 976-996.

-

- 2. Z. Liu, H. Su, B. Chen, J. Li, and S. I. Woo, Chem. Eng. J. 299 (2016) 255-262.

-

- 3. W. Xie, Y. Yu, and H. He, J. Environ. Sci. 75 (2019) 396-407.

-

- 4. R. Yang, Y. Cui, Q. Yan Q, C. Zhang, L. Qiu, D. O'Hare, and Q. Wang, Chem. Eng. J. 326 (2017) 656-666.

-

- 5. A. B. López, D. L. Castelló, and J. A. Anderson, Appl. Catal., B. 198 (2016) 189-199.

-

- 6. M. Li, V. G. Easterling, and M. P. Harold, Appl. Catal., B. 184 (2016) 364-380.

-

- 7. A. W. L. Ting, V. Balakotaiah, and M. P. Harold. Chem. Eng. J. 370 (2019) 1493-1510.

-

- 8. I. A. Resitoglu and A. Keskin, Int. J. Hydrogen Energy. 42 (2017) 23389-23394.

-

- 9. D. K. Pappas, T. Boningari, P. Boolchand, and P. G. Smirniotis, J. Catal. 334 (2016) 1-13.

-

- 10. J Han, J. Meeprasert, P. Maitarad, S. Nammuangruk, L. Shi, and D. Zhang, J. Phys. Chem. C. 120 (2016) 1523-1533.

-

- 11. Y. Zheng, D. Luss, and M. P. Harold, SAE Int. J. Engines, 7 (2014) 1280-1289.

-

- 12. J. Barman, S. Arora, R. Khan, and M. Parashar, SAE Technical Paper 1 (2016) 1733.

-

- 13. A. B. López, D. L. Castelló, A. J. McCue, and J. A. Anderson, Appl. Catal., B. 198 (2016) 266-275.

-

- 14. Z. Zhang, B. Chen, X. Wang, L. Xu, C. Au, C. Shi, and M. Crocker, Appl. Catal., B 165 (2015) 232-244.

-

- 15. V. A. Santiago, A. D. Quiñonero, I. S. Basáñez, D. L. Castelló, and A. B. López, Appl. Catal., B. 220 (2018) 524-532.

-

- 16. E. Srinivasa Rao and P. Manohar, J. Ceram. Process. Res. 17 (2016) 448-453.

- 17. F. A. Lafossas, C. Manetas, A. Mohammadi, G. Koltsakis, M. Iida, and K. Yoshida, AIChE J. 63 (2017) 2117-2127.

-

- 18. J. K. Unni, D. Bhatia, V. Dutta, L. M. Das, S Jilakara, and G. P. Subash, SAE Int. J. Engines. 10 (2017) 46-54.

-

- 19. K. Lee and K. W. Nam, J. Ceram. Process. Res. 19 (2018) 54-64.

- 20. X. Yuan, Y. Gao, and X. Wang, Int. J. Engine Res. 17 (2016) 169-178.

-

- 21. M. Han and B. Lee, Int. J. Automot. Technol. 16 (2015) 371-378.

-

- 22. J. S. Park, J. G. Yeo, S. C. Yang, and C. H. Cho, J. Ceram. Process. Res. 19 (2018) 20-24.

- 23. H. Gu, K. M. Chun, and S. Song, Int. J. Hydrogen Energy. 40 (2015) 9602-9610.

-

- 24. X. Cheng, D. Su, Z. Wang, C. Ma, and M. Wang, Int. J. Hydrogen Energy. 43 (2018) 21969-21981.

-

- 25. I. A. Resitoglu, A. Keskin, H. Özarslan, and H. Bulut, Int. J. Environ. Sci. Technol. 16 (2019) 6959-6966.

-

- 26. U. De-La-Torre, B. Pereda-Ayo, M. Moliner, and A. Corma, Appl. Catal., B 187 (2016) 419-4.

-

- 27. E. R. Rangel, J Ceram. Process. Res. 9 (2008) 61-63.

- 28. I. Cornejo, P. Nikrityuk, and R. E. Hayes, Chem. Eng. Sci. 175 (2018) 377-386.

-

- 29. C. P. Cho, Y. D. Pyo, J. Y. Jang, G. C. Kim, and Y. J. Shin, Appl. Therm. Eng. 110 (2017) 18-24.

-

- 30. P. Baskar, and A. Senthilkumar, Eng. Sci. Technol. 19 (2016) 438-443.

-

- 31. B. Pereda-Ayo, R. López-Fonseca, and J. R. González-Velasco, Appl. Catal., A. 363 (2009) 73-80.

-

- 32. C. Agrafioti and, A. Tsetsekou, J. Eur. Ceram. Soc. 20 (2000) 815-824.

-

- 33. B. Pereda-Ayo, D. Duraiswami, J. A. González-Marcos, and J. R. González-Velasco, Chem. Eng. J. 169 (2011) 58-67.

-

- 34. S. P. Venkatesan and P. N. Kadiresh, Int. J. Ambient Energy. 37 (2016) 64-67.

-

- 35. S. Yuvaraj, K. M. Kiran Babu, P. Kaleeshwaran, and S. Tamilselvan, Lecture Notes in Mechanical Engineering. Springer, Singapore, (2017) 231-238.

-

This Article

This Article

-

2019; 20(6): 621-631

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.621

- Received on Oct 10, 2019

- Revised on Oct 22, 2019

- Accepted on Oct 28, 2019

Services

Services

- Abstract

introduction

literature review

proposed research work

experimental setup and design

engine specification

nox storage and reduction & s elective catalytic converter

design and fabrication of reactor prototype

experimental procedure

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Rekha Durairaj

-

Department of Automobile Engineering, PSG College of Technology, Coimbatore, TN 641004, India

Tel : +919994367552 Fax: +04222573833 - E-mail: reksun02@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.