- Y2O3-stabilized ZrO2, Ni, and graphene-added Mg by reactive mechanical grinding processing for hydrogen storage and comparison with Ni and Fe2O3 or MnO-added Mg

Myoung Youp Songa,*, Eunho Choib and Young Jun Kwaka

aDivision of Advanced Materials Engineering, Hydrogen & Fuel Cell Research Center, Engineering Research Institute, Jeonbuk National University, 567 Baekje-daero, Deokjin-gu, Jeonju 54896, Korea

bDepartment of Materials Engineering, Graduate School, Jeonbuk National University, 567 Baekje-daero, Deokjin-gu, Jeonju 54896, Korea

The optimum powder to ball

ratio was examined, which is one of the important conditions in reactive

mechanical grinding processing. Yttria (Y2O3)-stabilized

zirconia (ZrO2) (YSZ), Ni, and graphene were chosen as additives to

enhance the hydriding and dehydriding rates of Mg. Samples with a

composition of 92.5 wt% Mg + 2.5 wt% YSZ + 2.5 wt% Ni + 2.5 wt% graphene (designated as

Mg-2.5YSZ-2.5Ni-2.5graphene) were prepared by grinding in hydrogen atmosphere.

Mg-2.5YSZ-2.5Ni-2.5graphene had a high effective hydrogen-storage capacity of

almost 7 wt% (6.85 wt%) at 623 K in 12 bar H2 at the second cycle (n

= 2). Mg-2.5YSZ-2.5Ni-2.5graphene contained Mg2Ni phase after

hydriding-dehydriding cycling. Mg-2.5YSZ-2.5Ni-2.5graphene had a larger

quantity of hydrogen absorbed for 60 min, Ha (60 min), than

Mg-2.5Ni-2.5graphene and Mg-2.5graphene. The addition of YSZ also increased the

initial dehydriding rate and the quantity of hydrogen released for 60 min, Hd

(60 min), compared with those of Mg-2.5Ni-2.5graphene. Y2O3-stabilized

ZrO2, Ni, and graphene-added Mg had a higher initial hydriding rate

and a larger Ha (60 min) than Fe2O3, MnO,

or Ni and Fe2O3-added Mg at n = 1.

Keywords: Hydrogen storage, Grinding in H2, Scanning electron microscopy (SEM), X-ray diffraction, YSZ, Ni, graphene addition

Magnesium (Mg) has several good properties for hydrogen

storage: it has high hydrogen storage capacity (7.6 wt%

based on magnesium hydride (MgH2) weight and 8.3 wt% based on

Mg weight), is relatively inexpensive, and has high reserves in the earth’s

crust. However, the reaction kinetics of magnesium with hydrogen is slow. The

potential of magnesium hydride as a reversible hydrogen storage medium has

drawn attention to improving the reaction kinetics of magnesium

with hydrogen [1]. Many researchers have attempted to increase the hydrogen

absorption and release rates of magnesium [2-7] by alloying with

magnesium transition metals [8, 9] such as Cu, Ni, Ti, and Fe and

by synthesizing compounds such as LaMg12 and CeMg12 [10].

Oxides can be easily pulverized during mechanical grinding

since they are brittle. The added oxides and/or the oxides pulverized during

mechanical grinding can make the particles of magnesium finer. The hydriding and

dehydriding kinetics of Mg have also been improved by the

additions to MgH2 or Mg of V2O5, VN or VC

[11], Cr2O3 [12], Nb2O5 [13-16],

MgO [17], Cr2O3, Al2O3

and CeO2 [18], CeO2 [19], and Y2O3

[20]. Addition of nano-sized oxides to Mg

[21, 22] and coating of Ni on the Mg particles [23] are expected to improve the

hydrogen-storage properties of Mg. We were interested in Yttria (Y2O3)-stabilized

zirconia (ZrO2) (YSZ) as an additive. Due to its

hardness and chemical inertness, it is used for tooth crowns [24]; and due to its hardness and optical properties in

monocrystal form, is used as jewelry.

YSZ is also used as the solid electrolyte in solid oxide fuel

cells (SOFCs) [24].

The addition of Ni to Mg is known to increase the hydriding

and dehydriding rates of Mg [25-28]. Graphite, one

of the allotropes of carbon, has high thermal conductivity

compared with most metals. When graphite is added to

Mg, it can thus help the sample disperse heat rapidly. The average specific

gravity of graphite is 1.6-2.0, which is smaller than the specific gravity of

aluminum, and the specific surface area of graphite is large. Graphene, another

allotrope of carbon, has a theoretical specific surface

area (SSA) of 2,630 m2/g [29].

We were also interested in Ni and graphene as additives.

One of the important

conditions in reactive mechanical grinding processing is powder to ball ratio. In this

work, the optimum powder to ball ratio was examined. Yttria (Y2O3)-stabilized

zirconia (ZrO2) (YSZ), Ni, and graphene were

expected to increase the hydriding and dehydriding rates of Mg when added. They

were thus chosen as additives. Samples with a composition of 92.5 wt%

Mg + 2.5 wt% YSZ + 2.5 wt% Ni + 2.5 wt% graphene

were prepared by grinding in a planetary ball mill in hydrogen atmosphere (reactive

mechanical grinding). The hydriding and dehydriding properties of the prepared

samples were examined. The samples were designated as

Mg-2.5YSZ-2.5Ni-2.5graphene. The initial hydriding rate and the quantity of

hydrogen absorbed for 60 min, Ha (60 min), of Y2O3-stabilized

ZrO2, Ni, and graphene-added Mg at the first cycle were compared

with those of Fe2O3, MnO, or Ni and Fe2O3-added

Mg.

The optimum powder to ball ratio for Mg-10 Fe2O3

with a composition of 90 wt% Mg + 10 wt% Fe2O3 was

examined varying the powder to ball ratios (weight ratio of powder to ball)

among 1/45, 1/27, and 1/9. The average particle size of Fe2O3

used for this experiment was smaller than 5 μm.

The starting materials to prepare the sample Mg-2.5YSZ-2.5Ni-2.5

graphene were pure Mg powder (-20 +100 mesh, 99.8%, metals basis,

Alfa Aesar), YSZ (partially-stabilized zirconia powder with

uniform dispersion of 3 mol% yttria, prepared by the co-precipitation method, Tosoh, Japan), Ni (Nickel

powder APS, 2.2-3.0 µm, purity 99.9% metal basis, C typically < 0.1%,

Alfa Aesar), and graphene (3-10 multi-layer graphene, 5-10 µm, purity ≥ 99

wt%, thickness 3-6 nm, surface area 150 m2/g, chemical exfoliation

proprietary method, Carbon Nano-material Technology Co., Ltd).

Reactive mechanical grinding was performed in a planetary

ball mill (Planetary Mono Mill; Pulverisette 6, Fritsch). Mixtures with a

composition of 92.5 wt% Mg + 2.5 wt% YSZ + 2.5 wt% Ni (total weight = 7.8 g)

were mixed in a stainless steel container (with 105 hardened steel balls, total

weight = 360 g) that was hermetically sealed. In order to prevent oxidation,

all sample handling was performed in a glove box filled with Ar. The disc

revolution speed was 400 rpm. The mill container (volume of 250 ml) was then filled

with high-purity hydrogen gas (≈ 12 bar). The reactive mechanical grinding

was performed for 12 h, refilling the hydrogen every two hours.

To prepare Mg-2.5YSZ-2.5Ni-5graphene, the addition

of graphene (0.2 g) was also performed in a planetary ball mill (Planetary Mono

Mill; Pulverisette 6, Fritsch) under similar conditions to those for the

preparation of 92.5 wt% Mg + 2.5 wt% YSZ + 2.5 wt% Ni for 30 min. The sample to

ball weight ratio was 1/45.

The absorbed or released hydrogen quantity was measured

as a function of time using a volumetric method with a

Sievert’s type hydriding and dehydriding apparatus

that was previously described [30]. During the measurements, the hydrogen

pressures were maintained as nearly constant by replenishing

the absorbed hydrogen from a small reservoir of known volume during the hydriding

reaction and by removing the released hydrogen to the small

reservoir during the dehydriding reaction. The 0.5 g of the samples was used

for the measurement of the absorbed or released hydrogen quantity as a function

of time. After the absorbed and then released hydrogen quantities were measured

at 623 K for 1 h in 12 and 1.0 bar H2, respectively, the sample was

then dehydrided at 623 K in a vacuum for 2 h.

Samples after reactive mechanical grinding and after

hydriding-dehydriding cycling were characterized by X-ray diffraction (XRD)

with Cu Kα radiation, using a Rigaku D/MAX 2500 powder diffractometer. The

microstructures of the powders were observed using a JSM-5900

scanning electron microscope (SEM) operated at 15 kV.

The quantity of hydrogen absorbed by the sample, Ha,

and the quantity of hydrogen released by the sample, Hd, were both

defined using the sample weight as a standard. Ha and Hd

were expressed in the unit of wt% H. The initial hydriding rate (wt% H/min) was

defined as the quantity of hydrogen charged for the first 2.5 min

divided by 2.5. The initial dehydriding rate (wt% H/min) was defined as the

quantity of hydrogen discharged for the first 2.5 min divided by 2.5.

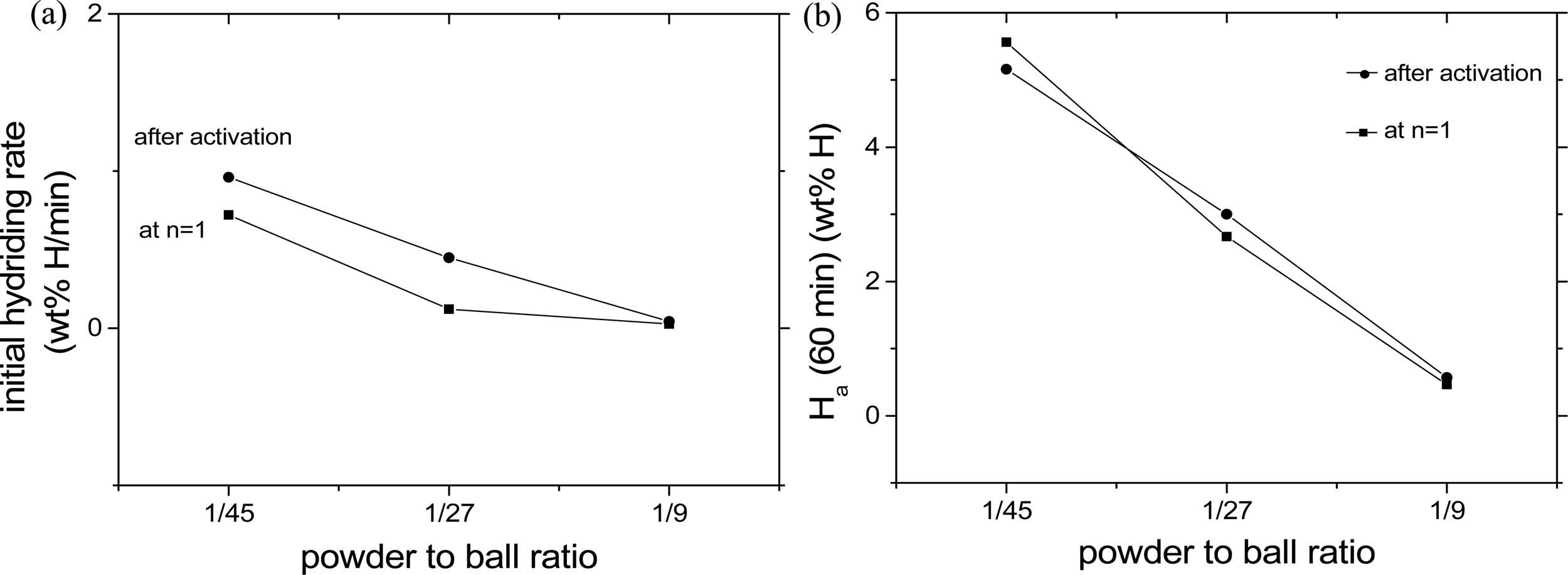

The variations in the initial hydriding rate and the

quantity of hydrogen absorbed for 60 min, Ha (60 min), at 593K in 12

bar H2 with the powder to ball ratio (1/45, 1/27, and 1/9) at

n = 1 and after activation (at n = 2) for Mg-10 Fe2O3

with a composition of 90 wt% Mg + 10 wt% Fe2O3

are shown in Fig. 1. The starting materials to prepare

the sample Mg-10Fe2O3 (at a revolution speed 250 rpm and

by reactive mechanical grinding for 2 h) were pure Mg powder (particle size 50 μm)

and Fe2O3 (< 5 μm, purity 99+%, Aldrich) [31]. At

n = 1 and after activation (at n = 2), the initial

hydriding rate decreased as the powder to ball ratio

increased; the initial hydriding rates were the highest when the

powder to ball ratio was 1/45. The initial hydriding rates after

activation were higher than those at n = 1.

At n = 1 and after activation

(at n = 2), Ha (60 min) decreased as the powder to ball

ratio increased; Ha (60 min)’s were the largest when the powder to

ball ratio was 1/45. At the powder to ball ratio of 1/45, the Ha (60

min) after activation was smaller than that at n = 1. On the other

hand, at the powder to ball ratio of 1/27 and 1/9, the Ha (60 min)’s

after activation were larger than that at n = 1. The decreases in the

initial hydriding rate and Ha (60 min) with the increase in the

powder to ball ratio show that the milling effects got better as the powder to

ball ratio increased.

From the results in Fig. 1, the powder to ball ratio of

1/45 was used in the process of reactive mechanical grinding for sample

preparation.

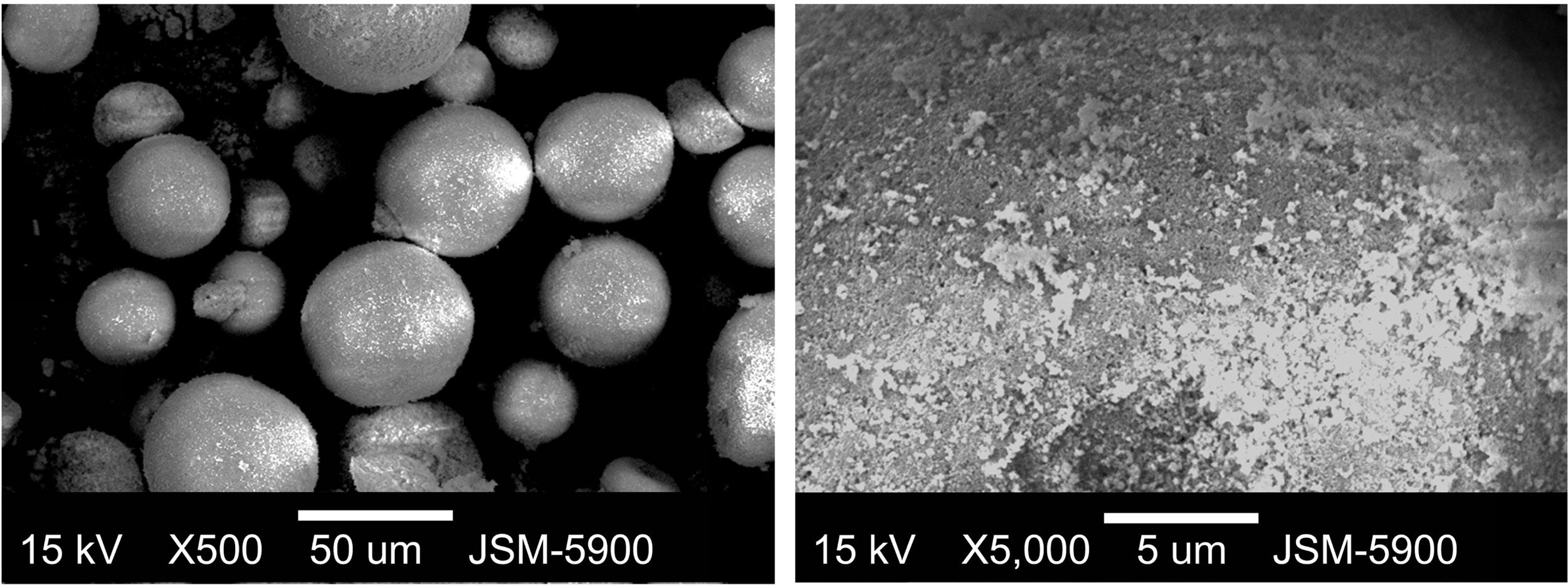

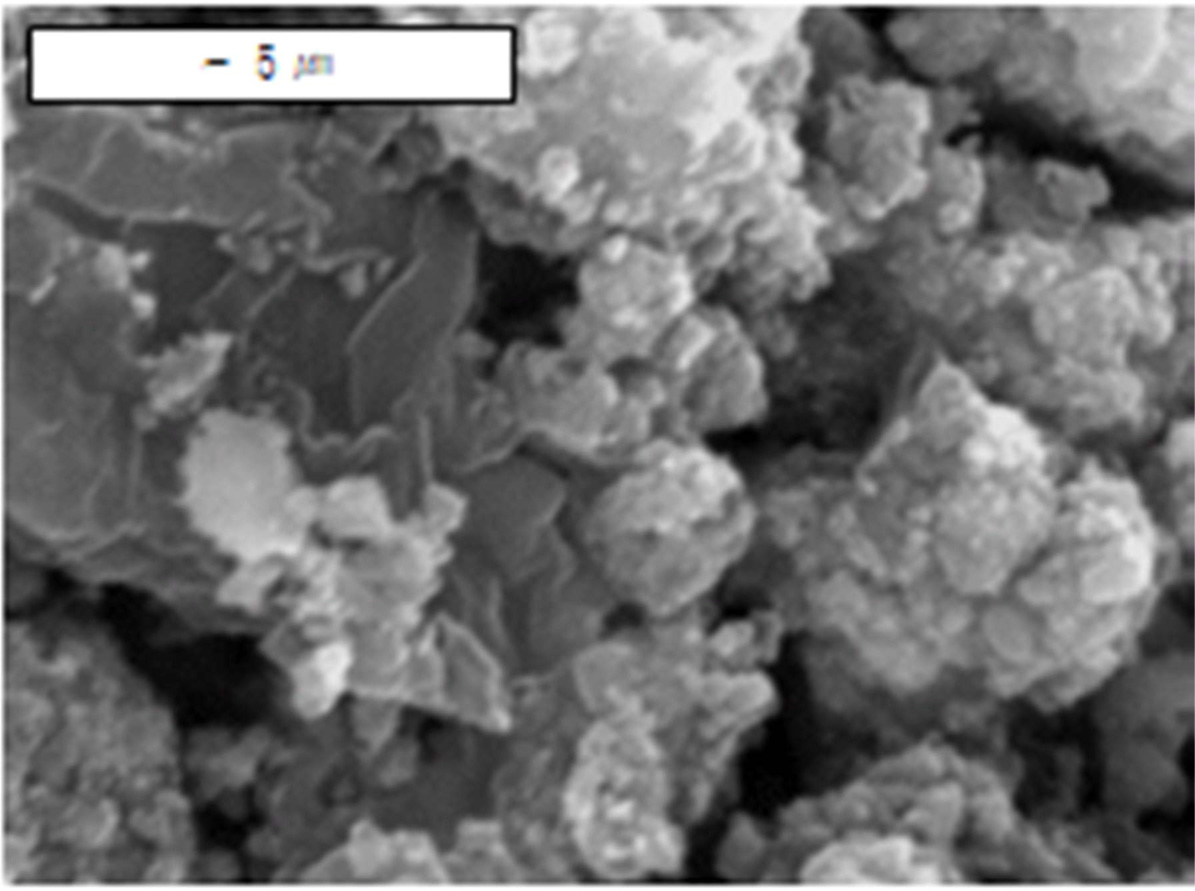

The SEM micrographs of YSZ at different magnifi- cations are shown in Fig. 2.

The particles were spherical and the particle sizes were not

homogeneous. The surfaces of particles were not smooth. The particles appeared

to consist of fine particles, their surfaces having many defects.

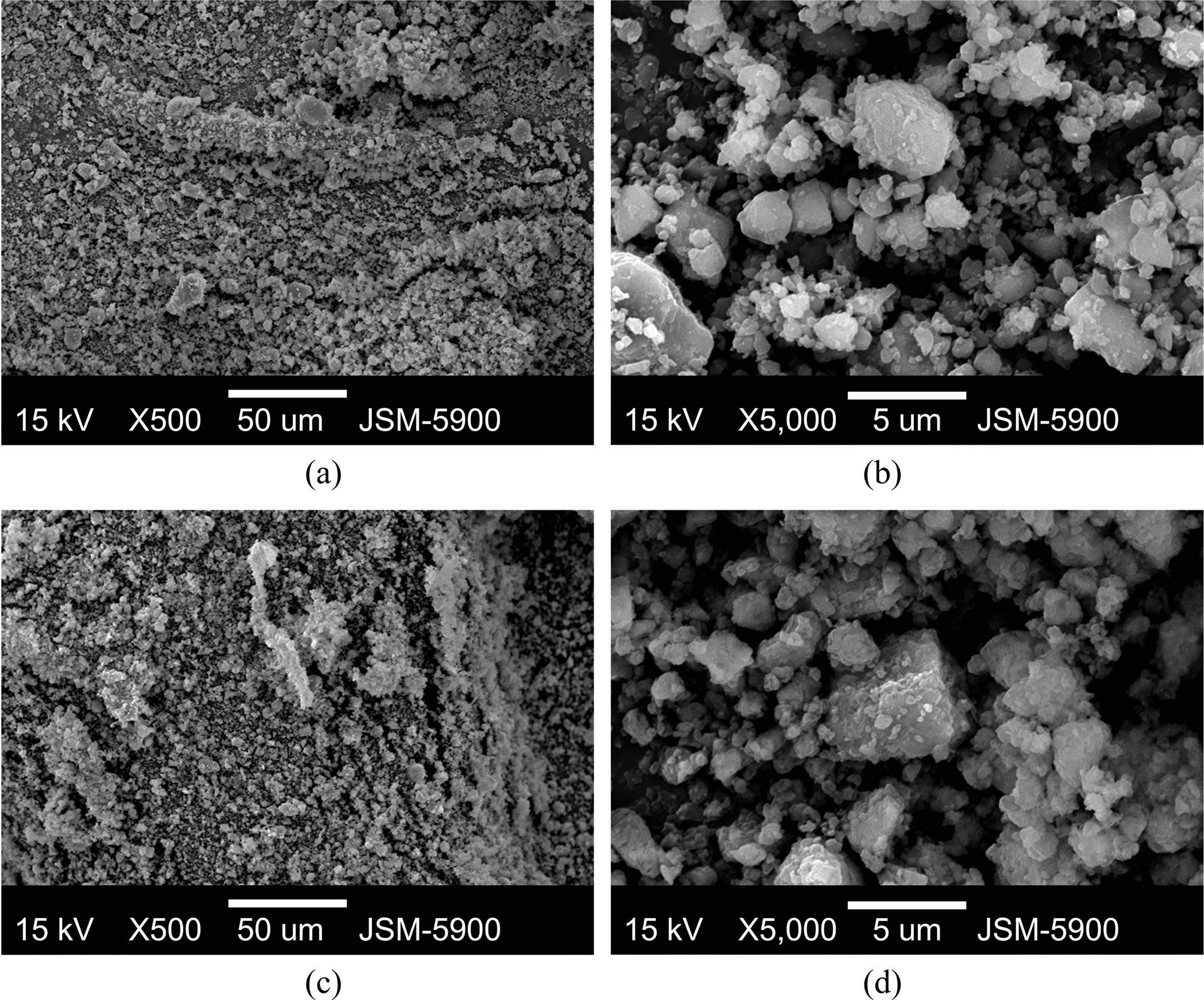

Fig. 3 shows the SEM micrographs at different

magnifications of Mg-2.5YSZ-2.5Ni-2.5graphene after reactive mechanical grinding

and dehydrided at the 4th hydriding-dehydriding cycle. The particle

sizes of the sample after reactive mechanical grinding were not homogeneous.

The surfaces of the particles were smooth. The

particles of this sample were much smaller than those of YSZ, indicating that

the YSZ particles were pulverized during reactive mechanical grinding. The particle

sizes of the sample dehydrided at the 4th hydriding-dehydriding

cycle were not homogeneous, either. The particle sizes of this sample were

similar to, but very slightly larger than, those of the sample after reactive

mechanical grinding. Maintenance at relatively high

temperatures during hydriding-dehydriding cycling is believed

to have brought about the sintering of particles and led to the very slight increase

in particle size.

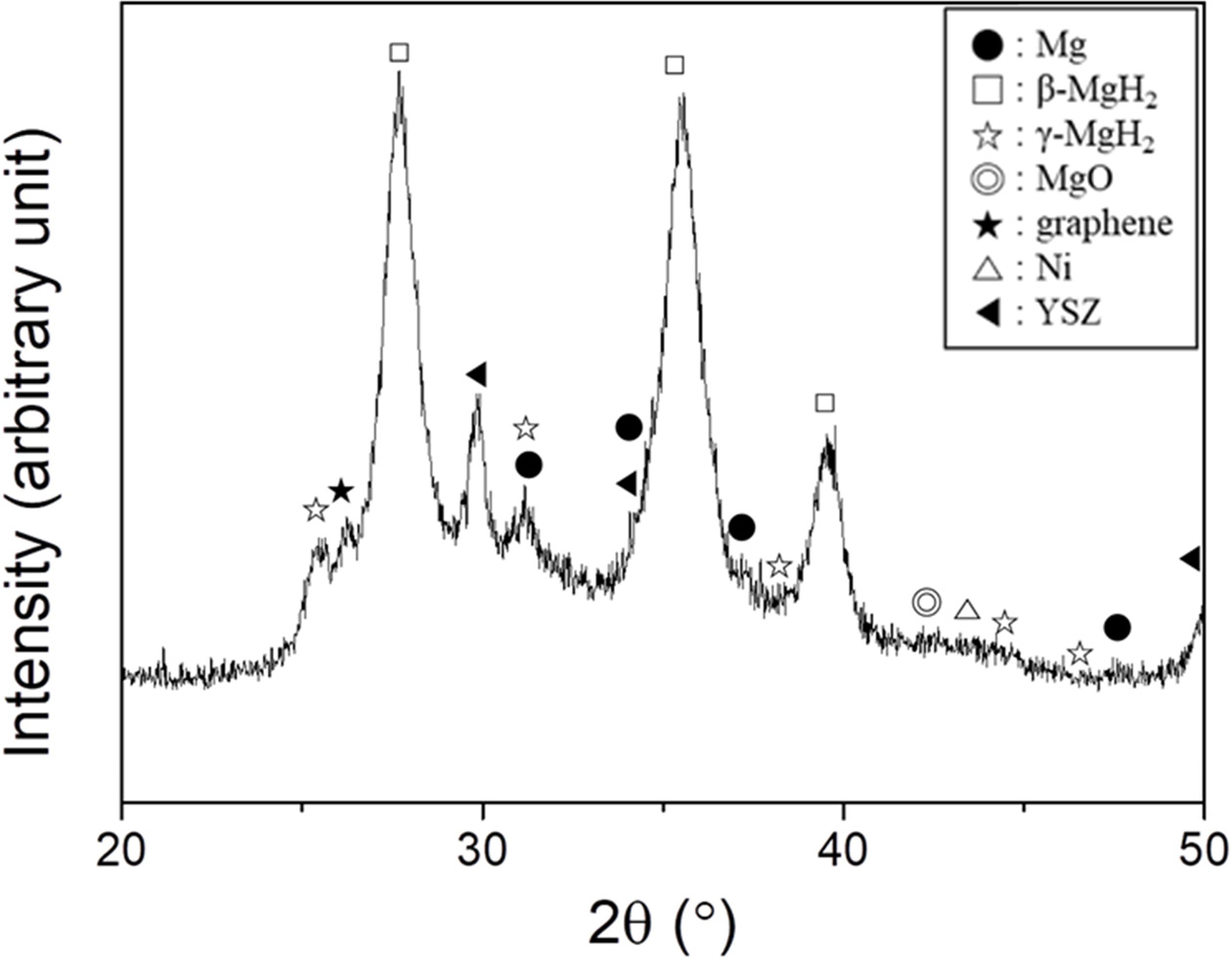

Fig. 4 shows the XRD pattern of

Mg-2.5YSZ-2.5Ni-2.5graphene after reactive mechanical grinding. The peaks were

quite broad and the background of the XRD pattern was quite high, showing that

reactive mechanical grinding had led to the formation of very small

crystallites. The sample contained a large amount of β-MgH2 with

small amounts of Mg, γ-MgH2, YSZ, Ni, graphene, and MgO. β-MgH2

and γ-MgH2 were formed by the reaction of Mg with H2

during grinding in hydrogen. The β-MgH2 is a low-pressure form of

magnesium hydride with tetragonal structure. The γ-MgH2 is a

high-pressure form of magnesium hydride with an orthorhombic unit cell

structure of α-PbO2 type, which usually forms in high hydrogen

pressure. MgO is believed to have been formed by the reaction of Mg with oxygen

adsorbed on the surfaces of as-purchased Mg particles.

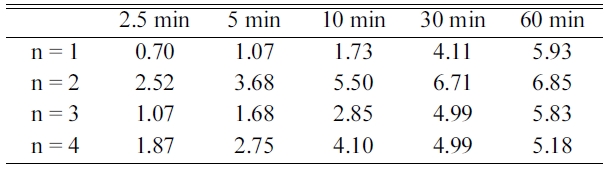

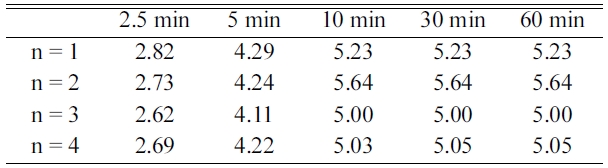

Table 1 presents the variations in Ha with t at

623 K in 12 bar H2 at CN = 1-4 for Mg-2.5YSZ-2.5Ni-2.5graphene.

As the number of cycles, n, increased from one to two, the initial hydriding

rate increased and from n = 2 to n = 3 or n = 4, the initial hydriding rate

decreased. The quantity of hydrogen absorbed for 60 min, Ha (60

min), increased from one to two, and decreased and from n = 2

to n = 4. From n = 1 to n = 2, the increase in the initial

hydriding rate was very large. Mg-2.5YSZ-2.5Ni-2.5 graphene absorbed 1.73 wt% H for 10 min

and 5.93 wt% H for 60 min at n = 1 and absorbed 5.50 wt% H for 10 min and 6.85

wt% H for 60 min at n = 2.

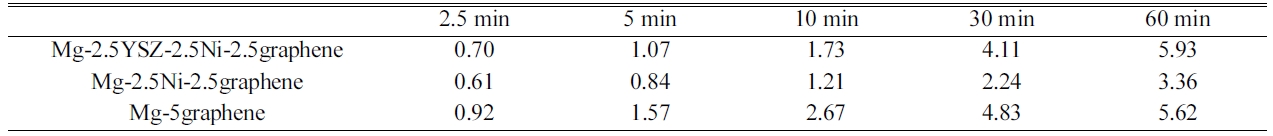

Table 2 presents the variations in Hd with t at

623 K in 1.0 bar H2 at n = 1-4 for Mg-2.5YSZ-2.5Ni-2.5graphene.

At n = 1, the initial dehydriding rate of Mg-2.5YSZ-2.5Ni-2.5graphene was quite

high and the quantity of hydrogen released for 60 min, Hd (60 min),

was quite large. As n increased from one to three, the initial dehydriding rate

decreased and the initial dehydriding rate increased from n = 3 to n = 4. The

quantity of hydrogen released for 60 min, Hd (60 min), increased

from n = 1 to n = 2 and decreased from n = 2 to n = 3 or n = 4.

Mg-2.5YSZ-2.5Ni-2.5graphene released 2.82 wt% H for 2.5 min and 5.23 wt% H for

60 min at n = 1 and released 2.73 wt% H for 2.5 min and 5.64 wt% H for 60 min

at n = 2.

Table 1 and 2 show that the activation of

Mg-2.5YSZ-2.5Ni-2.5graphene was completed after n = 2. An effective hydrogen

storage capacity was defined as the quantity of hydrogen absorbed for 60 min.

Mg-2.5YSZ-2.5Ni-2.5graphene had a high effective hydrogen-storage

capacity of almost 7 wt% (6.85 wt%) at 623 K in 12 bar H2 at n = 2.

The XRD pattern of Mg-2.5YSZ-2.5Ni-2.5graphene dehydrided

at the 4th hydriding-dehydriding cycle showed that the

sample contained a large amount of Mg and small amounts

of MgO and β-MgH2. Very small amounts of C, Mg2Ni,

and YSZ were also observed. MgO is believed to have been formed by the reaction

of Mg with oxygen adsorbed on the surfaces of Mg particles during treatment the

sample to obtain the XRD pattern. Graphene was changed to carbon after

hydriding-dehydriding cycling. Mg2Ni is believed to have been formed

by the reaction of Mg with Ni. The γ-MgH2, which was observed after

reactive mechanical grinding, is believed to have been transformed to β-MgH2

during hydriding-dehydriding cycling. The peaks in the XRD pattern were

sharp and the background of the XRD pattern was very high, showing that the

sample was well crystallized. The sample, which was quite amorphous

after reactive mechanical grinding, became crystalline.

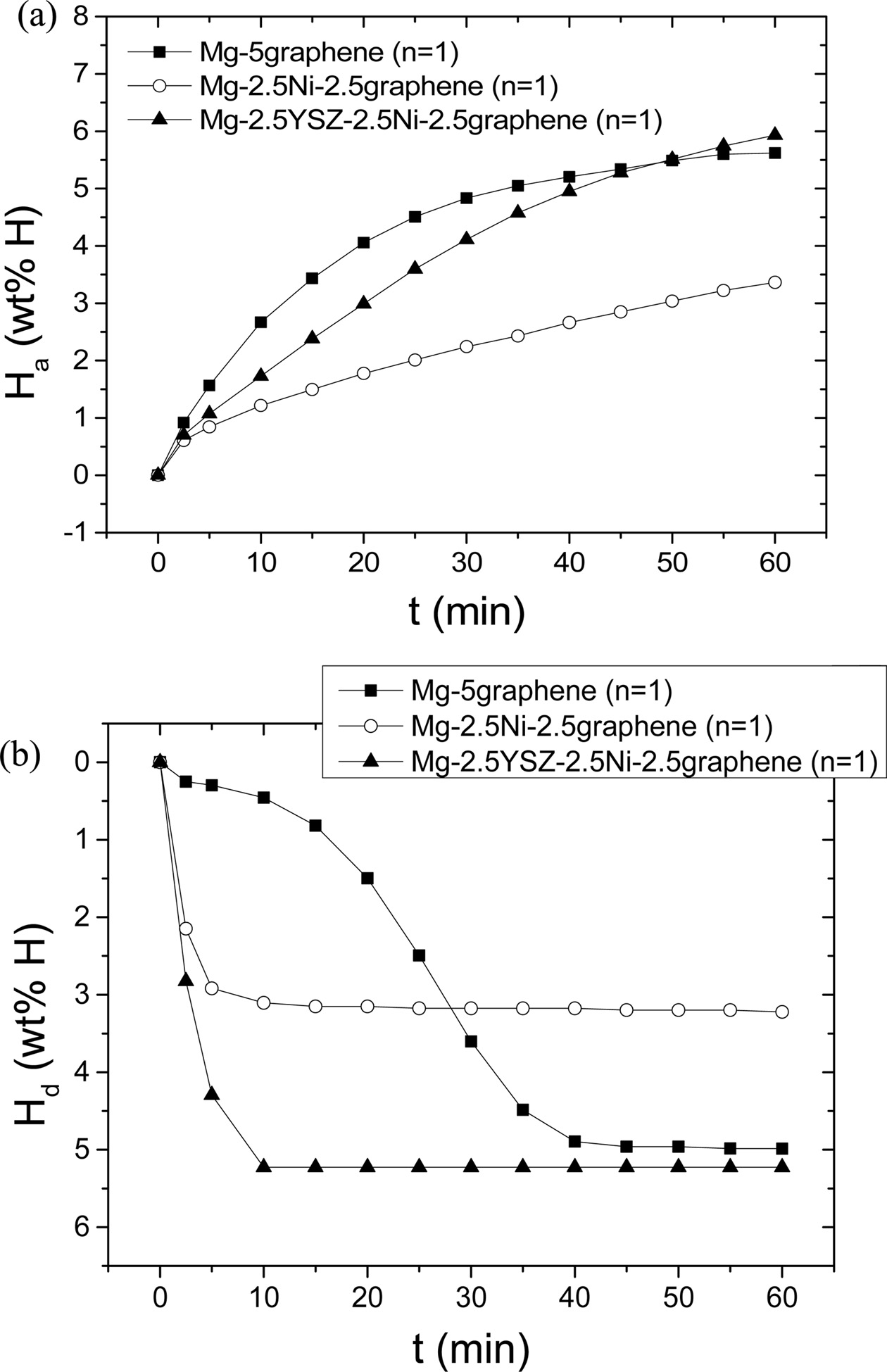

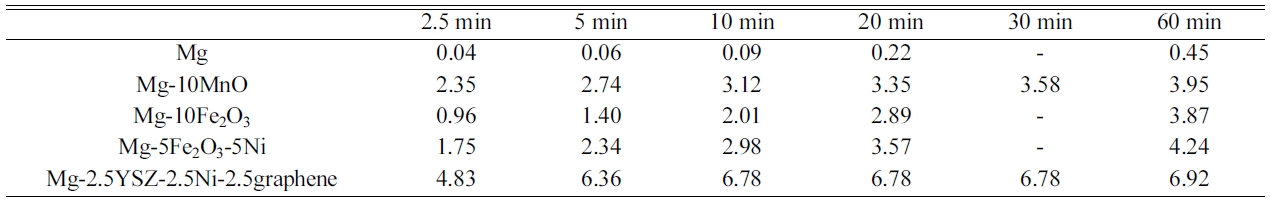

Fig. 5 shows the Ha vs. t curves at 623 K in 12

bar H2 and the Hd vs. t curves at 623 K in 1.0 bar H2

at n = 1 of a 95 wt% Mg + 5 wt% graphene alloy (named Mg-5graphene),

a 95 wt% Mg + 2.5 wt% Ni + 2.5 wt% graphene alloy (named Mg-2.5Ni-2.5graphene),

and Mg-2.5YSZ-2.5Ni-2.5graphene. Mg-5graphene and Mg-2.5Ni-2.5graphene

were prepared under similar conditions to those for preparing

Mg-2.5YSZ-2.5Ni-2.5graphene. Mg-5graphene had the highest initial hydriding

rate, followed in order by Mg-2.5YSZ-2.5Ni-2.5graphene and Mg-2.5Ni-2.5graphene.

Mg-2.5YSZ-2.5Ni-2.5graphene had the largest Ha (60 min), followed in

order by Mg-5graphene and Mg-2.5Ni-2.5graphene. Mg-2.5YSZ-2.5Ni-2.5graphene

absorbed 1.73 wt% H for 10 min and 5.93 wt% H for 60 min. Mg-5graphene absorbed

2.67 wt% H for 10 min and 5.62 wt% H for 60 min. Table 3

presents the variations in Ha with t at 623 K in 12 bar H2

at n = 1 for Mg-5graphene, Mg-2.5Ni-2.5 graphene, and

Mg-2.5YSZ-2.5Ni-2.5graphene. Mg-2.5YSZ-2.5Ni-2.5graphene dehydrided

at the 4th hydriding-dehydriding cycle contained Mg2Ni

phase. Mg-2.5Ni-2.5graphene after hydriding-dehydriding cycling also contained

the Mg2Ni phase. Mg2Ni is known to have higher hydriding

and dehydriding rates than Mg. The equilibrium plateau pressures at 623 K of

the Mg-H and Mg2Ni-H systems are 5.90 bar and 9.24 bar, respectively

[31, 32]. At 623 K in 12 bar H2, the driving forces for

the hydriding reaction of Mg and Mg2Ni, which are related to the

difference between the applied hydrogen pressure (12 bar H2 in this

work) and the equilibrium plateau pressure, were 6.10 bar and 2.76 bar,

respectively. The slow nucleation of Mg2NiH4 in Mg-2.5YSZ-2.5Ni-2.5graphene

and Mg-2.5Ni-2.5graphene due to the small driving force is believed to have led

to the lower initial hydriding rates of Mg-2.5YSZ-2.5Ni-2.5graphene and

Mg-2.5Ni-2.5graphene than that of Mg-5graphene. Mg-2.5YSZ-2.5Ni-2.5graphene had

a higher initial hydriding rate than Mg-2.5Ni-2.5graphene, suggesting

that the addition of YSZ increased the initial hydriding

rate. After a relatively long time, for example, after 60

min, the quantity of hydrogen absorbed by Mg-2.5YSZ-2.5Ni-2.5graphene

was larger than those by Mg-5graphene

and Mg-2.5Ni-2.5graphene. Mg-5graphene released a small amount of

hydrogen in the beginning (for 2.5 min) and then released hydrogen very slowly.

Thereafter, the dehydriding rate of Mg-5graphene increased

slowly, reaching its maximum after about 25 min, and was very low after 40 min.

The Hd vs. t curve for Mg-5graphene exhibited an S-shaped curve,

showing that the dehydriding reaction of Mg-5graphene progressed by the

nucleation and growth mechanism. Mg-2.5YSZ-2.5Ni-2.5graphene had the highest

initial dehydriding rate, followed in order by Mg-2.5Ni-2.5graphene and

Mg-5graphene. Mg-2.5YSZ-2.5Ni-2.5graphene had the largest Hd

(60 min), followed in order by Mg-5graphene and

Mg-2.5Ni-2.5graphene. At 623 K in 1.0 bar H2, the driving forces for

the dehydriding reaction of Mg and Mg2Ni, which are related to the

difference between the equilibrium plateau pressures and the applied hydrogen

pressure (1.0 bar H2 in this work), were 4.90 bar and 8.24

bar, respectively. The rapid nucleation of the Mg2Ni-H

solid solution in Mg-2.5Ni-2.5graphene and Mg-2.5YSZ-2.5Ni-2.5graphene

due to the large driving force is believed to have led to the

higher initial dehydriding rates of Mg-2.5Ni-2.5graphene and

Mg-2.5YSZ-2.5Ni-2.5graphene than that of Mg-2.5graphene. The addition of YSZ

also increased the initial dehydriding rate and Hd (60

min), compared with those of Mg-2.5Ni-2.5graphene.

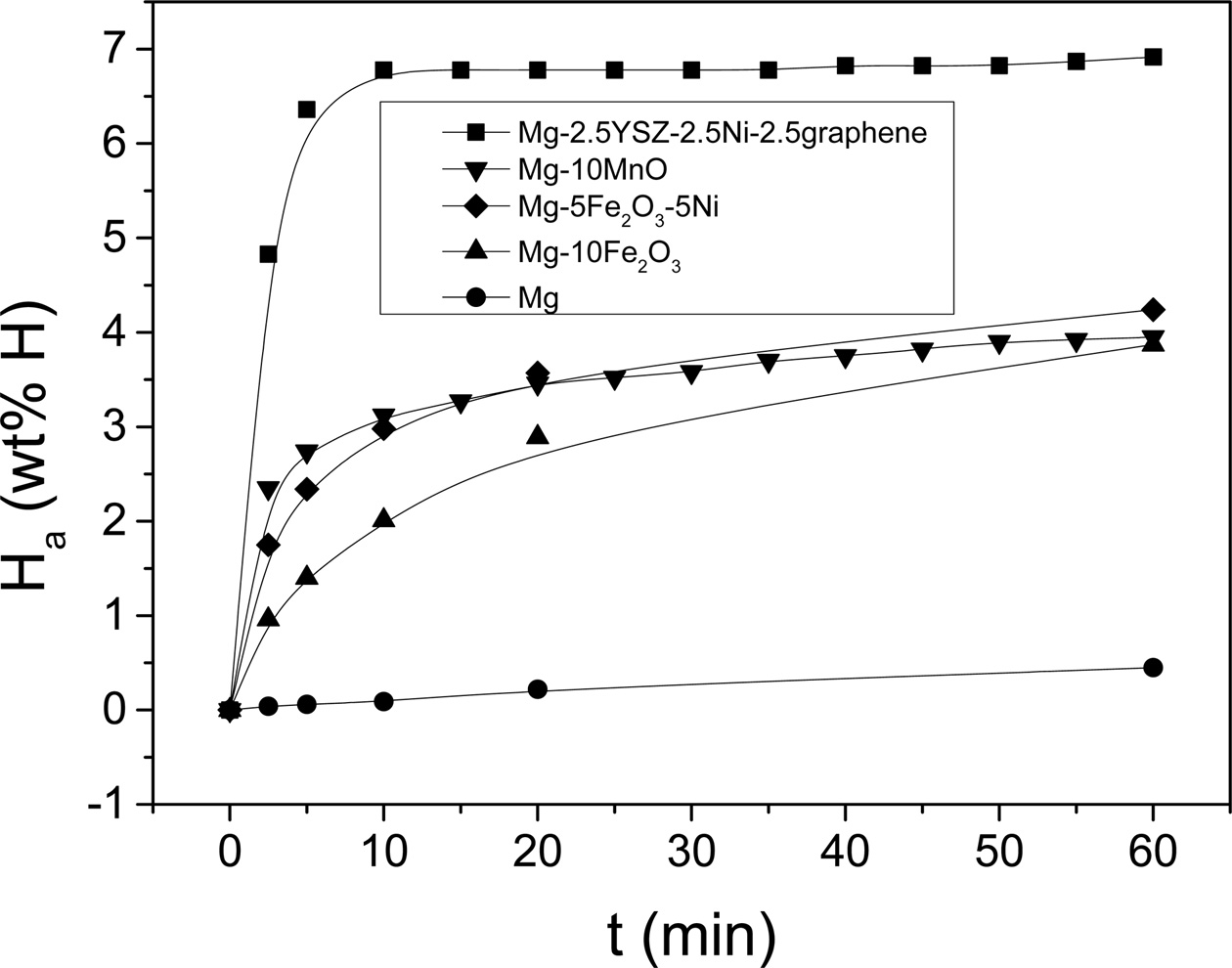

Fig. 6 shows the Ha vs. time t curves at 593 K

in 12 bar H2 at n = 1 for pure Mg (named Mg) [33], a 90 wt% Mg + 10

wt% MnO alloy (named Mg-10MnO) [34], a 90 wt% Mg + 10 wt% Fe2O3

alloy (named Mg-10Fe2O3) [35], 90 wt% Mg + 5 wt% Fe2O3

+ 5 wt% Ni (named Mg-5Fe2O3-5Ni) [35], and

Mg-2.5YSZ-2.5Ni-2.5graphene. The starting materials to prepare the

sample Mg-10MnO (at a revolution speed 250 rpm and by reactive

mechanical grinding for 2 h) were Mg powder (particle size 50 μm) and MnO

(88-250 μm, purity 99%, Aldrich) [34]. The starting materials to prepare the

samples Mg-10Fe2O3 and Mg-5Fe2O3-5Ni

(at a revolution speed 250 rpm and by reactive mechanical grinding for 2 h)

were Mg (assay ≥ 99%, grit; 50~150 mesh, Fluka,), Fe2O3

(nano-sized Fe2O3, prepared by spray conversion process,

about 36 nm), and Ni (purity 99.9%, average ~5 μm, CERAC) [35]. The Mg, Mg-10MnO,

Mg-10Fe2O3, and Mg-5Fe2O3-5Ni

samples were prepared under similar conditions to

those for preparing Mg-2.5YSZ-2.5Ni-2.5graphene. The Mg

absorbed hydrogen very slowly. Mg-2.5YSZ-2.5Ni-2.5graphene had the

highest initial hydriding rate, followed in order by Mg-10MnO,

Mg-5Fe2O3-5Ni, Mg-10Fe2O3, and Mg.

Mg-2.5YSZ-2.5Ni-2.5graphene had the largest Ha (60 min),

followed in order by Mg-5Fe2O3-5Ni, Mg-10MnO,

Mg-10Fe2O3, and Mg. Mg absorbed 0.04 wt% H for 2.5 min,

and 0.45 wt% H for 60 min [35]. Mg-2.5YSZ-2.5Ni-2.5graphene absorbed

4.83 wt% H for 2.5 min and 6.92 wt% H for 60 min. On the other hand, Mg-10Fe2O3

absorbed 0.96 wt% H for 2.5 min and 3.87 wt% H for 60 min

[35]. Table 4 summarizes the variations in absorbed hydrogen quantity (wt% H)

with time at 593 K in 12 bar H2 at n = 1 for these samples [33-35].

The considerably higher initial hydriding rate and

considerably larger Ha (60 min) of Mg-2.5YSZ-2.5Ni-2.5graphene

than Mg show that the addition of YSZ, Ni, and graphene significantly increased

the initial hydriding rate and Ha (60 min).

A SEM micrograph of Mg-10Fe2O3

hydrided at the 12th hydriding-dehydriding cycle [35] is shown in

Fig. 7. The particles of this sample were larger than those of

Mg-2.5YSZ-2.5Ni-2.5graphene dehydrided at the 4th

hydriding-dehydriding cycle, supporting well that the activated

Mg-2.5YSZ-2.5Ni-2.5graphene had a much higher initial hydriding rate and much

larger Ha (60 min) than the activated Mg-10Fe2O3.

The reactive mechanical

grinding of Mg with YSZ, Ni, and graphene is believed to have created defects

(leading to facilitation of nucleation), produced cracks and clean surfaces

(leading to increase in reactivity), and decreased particle sizes (leading to

diminution of diffusion distances or

increasing the flux of the diffusing hydrogen atoms) [36-43].

|

Fig. 1 Variations in (a) the initial hydriding rate and (b) the quantity of hydrogen absorbed for 60 min, Ha (60 min), at 593K in 12 bar H2 with the powder to ball ratio at n = 1 and after activation (at n = 2) for Mg-10Fe2O3. |

|

Fig. 2 SEM micrographs of YSZ at different magnifications. |

|

Fig. 3 SEM micrographs at different magnifications of Mg-2.5YSZ-2.5Ni-2.5graphene (a, b) after reactive mechanical grinding and (c, d) dehydrided at the 4th hydriding-dehydriding cycle. |

|

Fig. 4 XRD pattern of Mg-2.5YSZ-2.5Ni-2.5graphene after reactive mechanical grinding. |

|

Fig. 5 (a) Ha vs. t curves at 623 K in 12 bar H2 and (b) Hd vs. t curves at 623 K in 1.0 bar H2 at n = 1 for Mg-5graphene, Mg-2.5Ni-2.5graphene, and Mg-2.5YSZ-2.5Ni-2.5graphene. |

|

Fig. 6 Ha vs. t curves at 593 K in 12 bar H2 at n = 1 for Mg [33], Mg-10MnO [34], Mg-10Fe2O3 [35], Mg-5Fe2O3-5Ni [35], and Mg-2.5YSZ-2.5Ni-2.5graphene. |

|

Fig. 7 A SEM micrograph of Mg-10Fe2O3 hydrided at the 12th hydriding-dehydriding cycle [35]. |

|

Table 1 Variations in Ha with t at 623 K in 12 bar H2 at n = 1-4 for Mg-2.5YSZ-2.5Ni-2.5graphene. |

|

Table 2 Variations in Hd with t at 623 K in 1.0 bar H2 at n = 1-4 for Mg-2.5YSZ-2.5Ni-2.5graphene. |

|

Table 3 Variations in Ha with t at 623 K in 12 bar H2 at n = 1 for Mg-5graphene, Mg-2.5Ni-2.5graphene, and Mg-2.5YSZ-2.5Ni-2.5graphene. |

|

Table 4 Variations in absorbed hydrogen quantity (wt% H) with time at 593 K in 12 bar H2 at n = 1 for Mg, Mg-10MnO, Mg-10Fe2O3, Mg-5Fe2O3-5Ni, and Mg-2.5YSZ-2.5Ni -2.5graphene. |

The optimum powder to ball ratio for Mg-10 Fe2O3

was 1/45, which is one of the important conditions in reactive mechanical

grinding processing. Samples with a composition of 92.5 wt% Mg +

2.5 wt% YSZ + 2.5 wt% Ni + 2.5 wt% graphene (designated as Mg-2.5YSZ-2.5Ni-2.5graphene)

were prepared by grinding in hydrogen.

Mg-2.5YSZ-2.5Ni-2.5graphene was completely activated

after n = 2, having an effective hydrogen-storage capacity (the quantity of

hydrogen absorbed for 60 min) of almost 7 wt% (6.85 wt%) at 623 K in 12 bar H2

at n = 2. The sample absorbed 5.50 wt% H for 10 min and 6.85 wt% H for 60 min

in 12 bar H2 and released 2.73 wt% H for 2.5 min and 5.64 wt% H for

60 min in 1.0 bar H2, at 623 K at n = 2. Mg-2.5YSZ-2.5Ni-2.5graphene

contained Mg2Ni phase after hydriding-dehydriding

cycling. The slow nucleation of Mg2NiH4 in

Mg-2.5YSZ-2.5Ni-2.5graphene and Mg-2.5Ni-2.5 graphene due to the small driving

force is believed to have led to the lower initial hydriding rates than that of

Mg-5graphene. Mg-2.5YSZ-2.5Ni-2.5graphene had a higher

initial hydriding rate than Mg-2.5Ni-2.5graphene, suggesting

that the addition of YSZ increased the initial hydriding

rate. Mg-2.5YSZ-2.5Ni-2.5graphene had a larger Ha (60 min) than

Mg-2.5Ni-2.5graphene and Mg-2.5graphene. The rapid nucleation

of Mg2Ni-H solid solution in Mg-2.5Ni-2.5graphene and

Mg-2.5YSZ-2.5Ni-2.5graphene due to the large driving force is believed to have

led to their higher initial dehydriding rates than that of Mg-2.5graphene. The

addition of YSZ also increased the initial dehydriding rate and the Hd

(60 min), compared with those of Mg-2.5Ni-2.5 graphene. Y2O3-stabilized

ZrO2, Ni, and graphene-added Mg had a

higher initial hydriding rate and larger Ha (60 min) than Fe2O3,

MnO, or Ni and Fe2O3-added Mg at the first cycle.

This research was supported by Basic

Science Research Program through the National Research Foundation

of Korea (NRF) funded by the Ministry of Education (grant number

NRF-2017R1D1A1B03030515). This paper was supported by the

selection of research-oriented professor of Jeonbuk National University in

2019.

- 1. M.Y. Song, Y.J. Kwak, S.H. Lee, and H.R. Park, Korean J. Met. Mater. 51[2] (2013) 119-123.

-

- 2. Y. Wang, K. Luo, W. Ye, S. Du, J.S.Francisco, J. Yin, and P. Gao, Int. J. Hydrogen Energy 44[29] (2019) 15239-15245.

-

- 3. S. Niyomsoan, D.R. Leiva, R.A. Silva, L.F. Chanchetti, R.N. Shahid, S.Scudino, P. Gargarella, and W.J. Botta, Int. J. Hydrogen Energy 44[29] (2019) 23257-23266.

-

- 4. M.Y. Song, E. Choi, and Y.J. Kwak, Int. J. Hydrogen Energy 44[29] (2019) 3779-3789.

-

- 5. Y.J. Kwak, S.H. Lee, and M.Y. Song, J. Nanosci. Nanotech. 18[9] (2018) 6040-6046.

-

- 6. M.Y. Song, E. Choi, andY.J. Kwak, Mater. Res. Bull. 108 (2018) 23-31.

-

- 7. Y.J. Kwak, E. Choi, and M.Y. Song, Met. Mater. Int. 24[5] (2018) 1181-1190.

-

- 8. S.H. Hong, S.N. Kwon, and M.Y. Song, Korean J. Met. Mater. 49[4] (2011) 298-303.

-

- 9. J.J. Reilly and R.H. Wiswall Jr, Inorg. Chem. 7[11] (1968) 2254-2256.

-

- 10. J.M. Boulet and N. Gerard, J. Less-Common Met. 89 (1983) 151-161.

-

- 11. W. Oelerich, T. Klassen, and R. Bormann, J. Alloys Compd. 322 (2001) L5-9.

-

- 12. Z. Dehouche, T. Klassen, W. Oelerich, J. Goyette, T.K. Bose, and R. Schulz, J. Alloys Compd. 347 (2002) 319-323.

-

- 13. G. Barkhordarian, T. Klassen, and R. Bormann, Scripta Materialia 49 (2003) 213-217.

-

- 14. G. Barkhordarian, T. Klassen, and R. Bormann, J. Alloys Compd. 407[1-2] (2006) 249-255.

-

- 15. O. Friedrichs, T. Klassen, J.C. Sánchez-López, R. Bormann, and A. Fernández, Scripta Materialia 54[7] (2006) 1293-1297.

-

- 16. O. Friedrichs, F. Aguey-Zinsou, J.R. Ares Fernández, J.C. Sánchez-López, A. Justo, T. Klassen, R. Bormann, and A. Fernández, Acta Materialia 54[1] (2006) 105-110.

-

- 17. K.F. Aguey-Zinsou, J.R. Ares Fernandez, T. Klassen, and R. Bormann, Mat. Res. Bull. 41[6] (2006) 1118-1126.

-

- 18. M.Y. Song, J-L. Bobet, and B. Darriet, J. Alloys Compd. 340 (2002) 256-262.

-

- 19. S. Long, J. Zou, Y. Liu, X. Zeng, and W. Ding, J. Alloys Compd. 580 (Supplement 1) (2013) S167-170.

-

- 20. S. Long, J. Zou, Xi Chen, X. Zeng, and W. Ding, J. Alloys Compd. 615 (Supplement 1) (2014) S684-688.

-

- 21. J.-I. Song, G.-Y. Lee, J.-R. Kim, and J.-S. Lee, J. Cer. Proc. Res. 19[4] (2018) 279-284.

- 22. C.W. Park, J.H. Lee, S.H. Kang, J.H. Park, H.M. Kim, H.S. Kang, H.A. Lee, J.H. Lee, J.H. In, and K.B. Shim, J. Cer. Proc. Res. 19[2] (2018) 179-182.

- 23. S.-M. Sim, J. Cer. Proc. Res. 19[1] (2018) 1-4.

- 24. https://en.wikipedia.org/wiki/Yttria-stabilized_zirconia

- 25. S.-H. Hong and M.Y. Song, Korean J. Met. Mater. 54[2] (2016) 125-131.

-

- 26. M.Y. Song, Y.J. Kwak, S.H. Lee, and H.R. Park, Korean J. Met. Mater. 54[3] (2016) 210-216.

-

- 27. M.Y. Song, Y.J. Kwak, and H.R. Park, Korean J. Met. Mater. 54[7] (2016) 503-509.

-

- 28. S.N. Kwon, H.R. Park, and M.Y. Song, Korean J. Met. Mater. 54[7] (2016) 510-519.

- 29. https://en.wikipedia.org/wiki/Graphene

- 30. M.Y. Song, S.H. Baek, J.-L. Bobet, and S.H. Hong, Int. J. Hydrogen Energy 35 (2010) 10366-10372.

-

- 31. M.Y. Song and Y.J. Kwak, Korean J. Met. Mater. 56[3] (2018) 244-251.

- 32. M.Y. Song and H.R. Park, J. Alloys Compd. 270 (1998) 164-167.

-

- 33. M.Y. Song, Y.J. Kwak, S.H. Lee, and H.R. Park, Bull. Mater. Sci. 37[4] (2014) 831-835.

-

- 34. M.Y. Song, I.H. Kwon, S.N. Kwon, C.G. Park, S.H. Hong, J.S. Bae, and D.R. Mumm, J. Alloys Compd. 415 (2006) 266-270.

-

- 35. S.N. Kwon, Improvement of the hydrogen absorption and desorption kinetics of Mg by catalytic effects of Fe2O3 and Ni, M.E. thesis, Jeonbuk National University, February 22, 2008.

- 36. M.Y. Song, S.H. Lee, and D.R. Mumm, J. Cer. Proc. Res. 19[3] (2018) 211-217.

- 37. M.Y. Song, Y.J. Kwak, and S.H. Lee, J. Cer. Proc. Res. 20[2] (2019) 173-181.

- 38. S.-H. Hong and M.Y. Song, Korean J. Met. Mater. 56[2] (2018) 155-162.

-

- 39. M.Y. Song, E. Choi, and Y.J. Kwak, Korean J. Met. Mater. 56[5] (2018) 392-399.

-

- 40. M.Y. Song, Y.J. Kwak, and E. Choi, Korean J. Met. Mater. 56[7] (2018) 524-531.

-

- 41. M.Y. Song and Y.J. Kwak, Korean J. Met. Mater. 56[8] (2018) 611-619.

-

- 42. M.Y. Song, E. Choi, and Y.J. Kwak, Korean J. Met. Mater. 56[8] (2018) 620-627.

-

- 43. M.Y. Song and Y.J. Kwak, Korean J. Met. Mater. 56[12] (2018) 878-884.

-

This Article

This Article

-

2019; 20(6): 609-616

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.609

- Received on Aug 5, 2019

- Revised on Sep 26, 2019

- Accepted on Oct 7, 2019

Services

Services

- Abstract

introduction

experimental details

results and discussions

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Myoung Youp Song

-

Division of Advanced Materials Engineering, Hydrogen & Fuel Cell Research Center, Engineering Research Institute, Jeonbuk National University, 567 Baekje-daero, Deokjin-gu, Jeonju 54896, Korea

Tel : +82-63-270-2379 Fax: +82-63-270-2386 - E-mail: songmy@jbnu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.