- Structural and electrical properties of Ba(Sr,Ti)O3/K(Ta,Nb)O3 multilayer thin film for the application of electro-caloric devices

Min-Su Kwona, Sung-Gap Leea,*, Kyeong-Min Kima and Seungkeun Choib

aDept. of Materials Engineering and Convergence Technology, ERI, Gyeongsang National University, Jinju 52828, Korea

bSchool of STEM, Univ. of Washington, Bothell, WA, 98011, USA

In this study, the

multilayered thin films of (Ba,Sr)TiO3/K(Ta,Nb)O3 were

fabricated by the sol-gel and spin coating methods, and their structural and

electrical properties were investigated. The specimen showed polycrystalline

X-ray diffraction (XRD) characteristics with a tetragonal structure. The

average grain size and film thickness for one coating were about 30~40nm and

60nm, respectively. The phase transition temperature of specimen was lower than

10 oC. The dielectric constant and loss at 20 oC

of the specimen coated six times were 1,231 and 0.69, respectively. The rate of

change in dielectric constant at an applied direct current (DC) voltage of the

six times coated thin films was 17.3%/V. The electrocaloric effect was the

highest around the temperature at which the remanent polarization rapidly

changed. When an electric field of 660kV/cm was applied to the triply coated

thin films, the highest electrocaloric property of 4.41 oC was

observed.

Keywords: Ba(Sr,Ti)O3, K(Ta,Nb)O3, Multilayer thin film, Ferroelectric effect, Electro-caloric effect, Remanent polarization, Interface properties.

BaTiO3 ceramics with ABO3 perovskite

crystal structure is a typical ferroelectric material and has been

studied for application to various devices such as capacitors, piezoelectric

transducers, and infrared sensors using excellent structural and electrical

properties [1,2]. Also, K(Ta,Nb)O3 ceramics with the same

perovskite structure have been studied for application to electro-optic

devices, memory devices, and sensors by using various

structural characteristics and electrical properties depending

on the composition ratio of Ta and Nb [3,4]. Recently, BaTiO3

and K(Ta,Nb)O3 ceramics have attracted

attention as lead-free materials as environmental issues

become important social issues.

Studies on thin films have mainly been focused on the

changes in the manufacturing process and improvement of properties

of materials [5,6]. Also, research on the interfacial phenomenon of thin

film devices has mainly focused on the interface between substrate and thin film

[7]. Multilayer thin films, which have been stacked alternately

with different composition or materials, exhibit excellent

electrical properties due to the formation of super-lattice structures or

mixture compositions in the interfacial layer through epitaxial growth.

However, studies on the various electronic properties occurring at the

interface by laminating different materials have been carried out only in part,

despite a theoretical possibility.

Electronic devices have become more sophisticated and

complex, and devices are becoming more and more micronized. As a result, heat

generation problems in circuits and devices are recognized as important factors affecting the

performance of devices. The problems of heat

generation of devices are generally solved by using a heat dissipation

properties of substrates, but it is limited in performance and price. Recently,

as the need for cooling solutions for micro- or nanoelectronic devices with

high power or high density heat generation has increased, research has been

actively conducted on the electrocaloric effect in ferroelectric materials

using small and highly energy efficient properties. In 2005, A. S. Mischenko et

al. [9] reported a study on the application on ferroelectric Pb(Zr0.95Ti0.05)O3

thin films as cooling devices using electrocaloric

characteristics. However, since Pb(Zr,Ti)O3-based materials have a phase transition

temperature higher than 240 oC, applications of cooling devices

at room temperature are limited, and researches have been limited by

environmental problems caused by Pb element.

In this study, (Ba,Sr)TiO3/K(Ta,Nb)3

(BST/KTN) multilayer thin films were prepared by alternately laminating of

lead-free (Ba,Sr)TiO3 and K(Ta,Nb)O3 thin films And their

structural and electrical properties were investigated according to the number

of coatings of the specimens in order to investigate the application as cooling

devices.

(Ba0.7Sr0.3)TiO3 (BST)

and K(Ta0.6Nb0.4)O3 (KTN) with low phase

transition temperature were selected to investigate

the feasibility of the application as an cooling elements

capable of operating at room temperature [10,11].

BST precursor solutions were prepared by the sol-gel

method from barium acetate (Junsei Chemical Co., Japan, 99.0%), strontium

acetate 0.5-water (KANTO Chemical Co., Japan, 99.0%), titanium

(IV) iso-propoxide (Junsei Chemical Co., Japan, 99.0%),

as starting materials, with acetic acid and

2-methoxyethanol as solvents. And KTN precursor solutions were synthesized from

potassium acetate (CH3COOK, Sigma Aldrich, 99%), niobium

ethoxide (Nb(COH2CH3)5, Alfa aesar, 99.999%),

tantalum ethoxide (Ta(COH2CH3)5, Alfa aesar,

99.999%) with 2-methoxyethanol used a solvent. The molar con- centration of solution was adjusted to 0.3

M, and 10 mol% of excess potassium acetate was added to compensate for the expected K2O

losses during annealing.

BST/KTN multilayer thin films

were prepared by alternately coated BST and

KTN. Especially, to suppress ion diffusion at interface between thin films and

Pt/Ti/SiO2/Si substrates, BST thin films having excellent chemical

stability were coated on the substrate as the first layer. Structural and

electrical properties of BST/KTN multilayer thin films were investigated

according to the number of coatings.

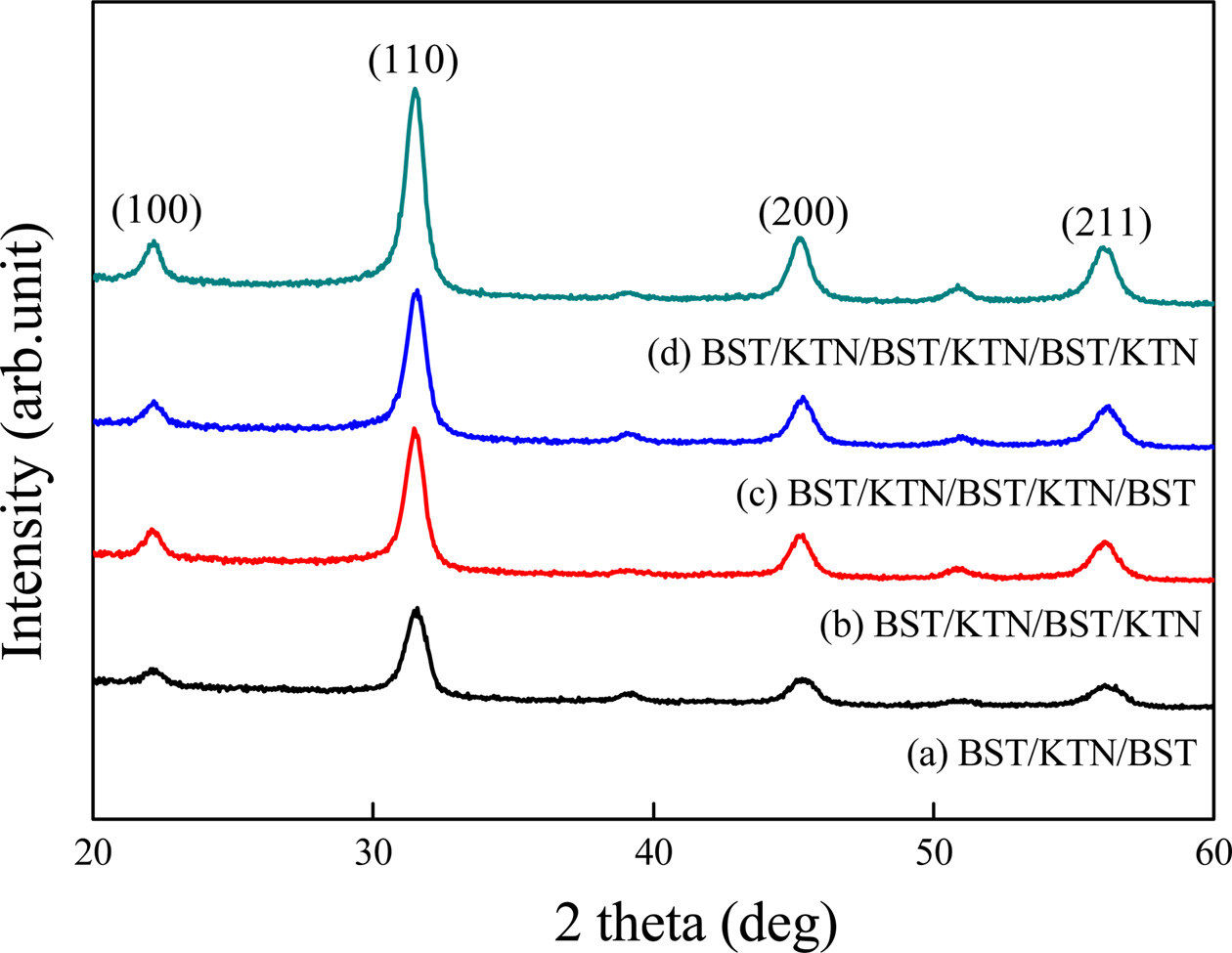

Fig. 1 shows X-ray diffraction (XRD) patterns of BST/KTN

multilayer thin films according to the number of coatings.

BST and KTN thin films were repeatedly coated from 3

times to 6 times on Pt/Ti/SiO2/Si substrates. Generally, single KTN

thin films were observed with a secondary phase such as K2Ta2O6

pyrochlore phase. However, in this study,

all specimens showed homogeneous

polycrystalline XRD patterns with tetragonal structure. This is because the BST

thin film coated with the first layer acts as a seed layer for KTN upper layer

crystal- lization and the crystal

structure of ABO3 perovskite having the same BST thin film and KTN

thin film [12]. As the number of coatings increased, crystallinity of

multilayer thin films improved as increasing XRD peaks intensities and

decreasing FWHM (full width at half maximum) values.

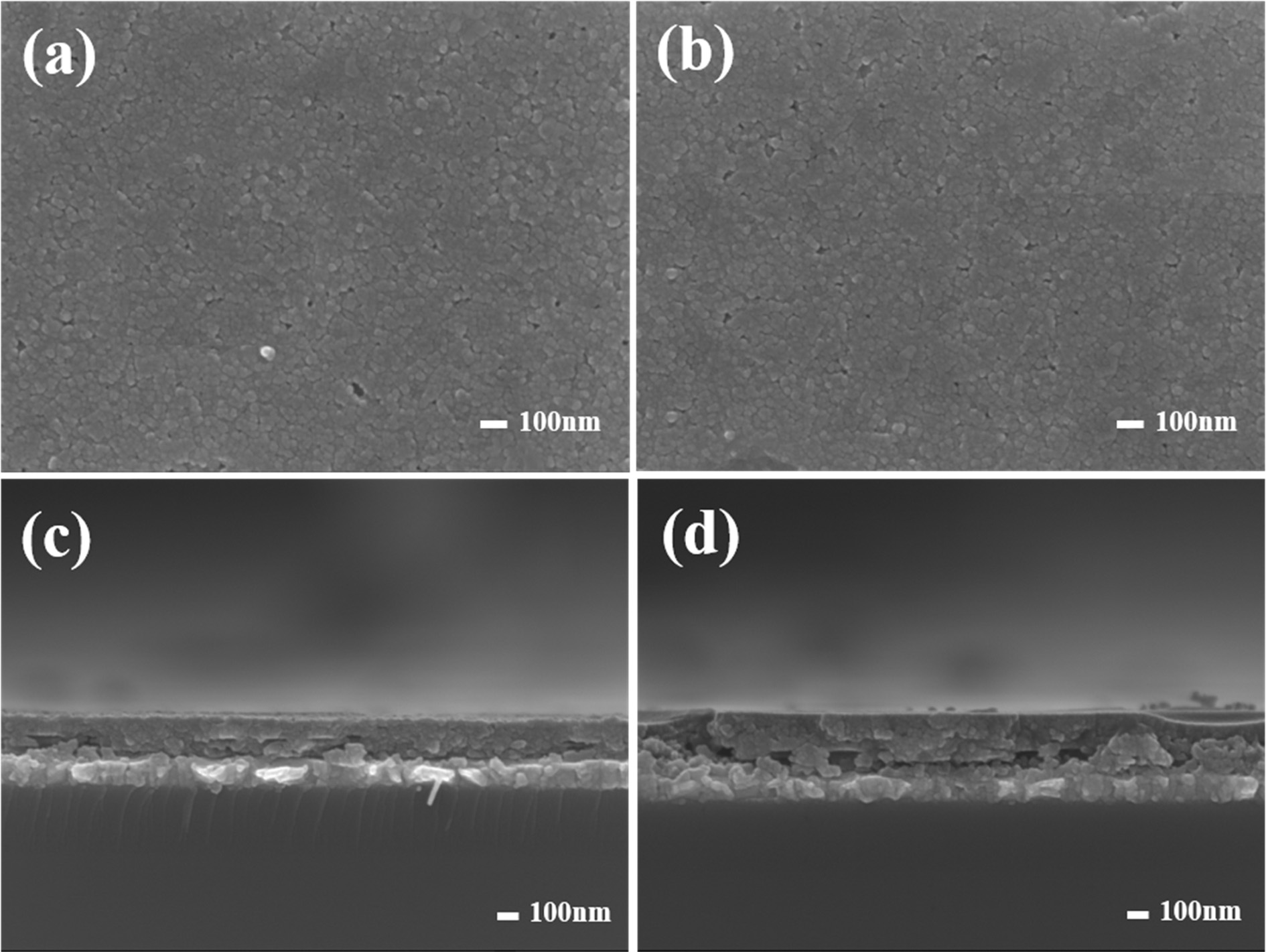

Fig. 2 shows surface and cross-sectional microstructures

of BST/KTN multilayer thin films according to the number of

coatings. All specimens showed dense crystal structure

composed of small and homogeneous grains, and average

grain size was about 30~40 nm. In general, KTN thin

films are difficult to fabricate specimens with homogeneous structure due to

high vapor pressure characteristics of K ions, and many pores are

distributed [13]. However, BST/KTN multilayer thin films showed

homogeneous and dense microstructure, probably due to the microstructure of the

lower BST thin film acting as the nucleation site of the upper KTN thin film.

Average thickness for one-time coated thin films was about 60 nm.

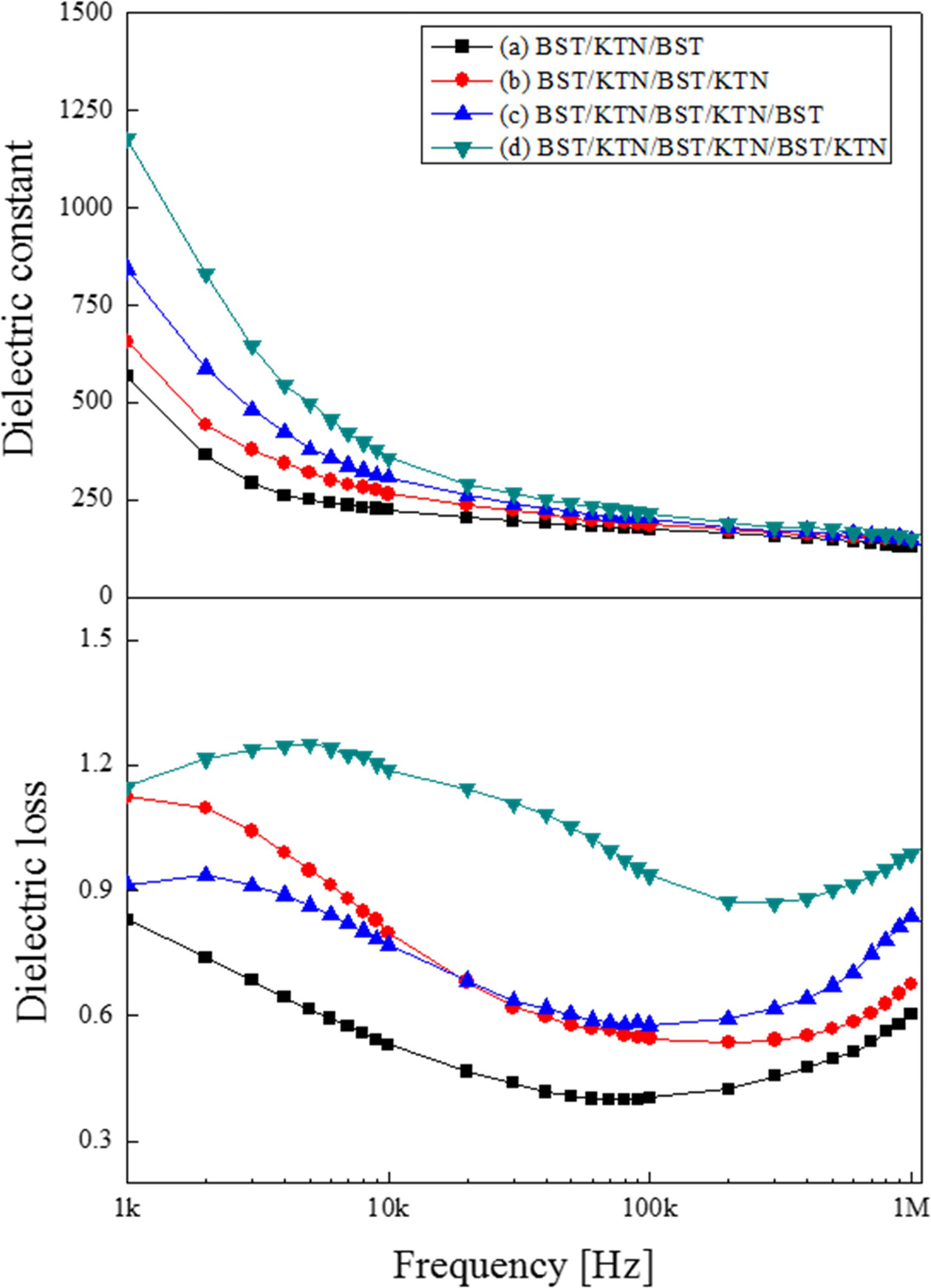

Fig. 3 shows dielectric constant and dielectric loss of BST/KTN

multilayer thin films with frequency application. All

specimens showed the typical dielectric relaxation characteristics [14].

Dielectric constant and dielectric loss increased with increasing the number of

coatings. This is probably due to the decrease in the stress on interfaces due

to the difference in lattice constant between Pt substrate and BST thin film.

Also, as the number of coatings increased, the slope of decrease in dielectric

constant with increasing frequency was increased due to the distribution of

space charge formed at interfaces between BST and KTN thin films [15, 16].

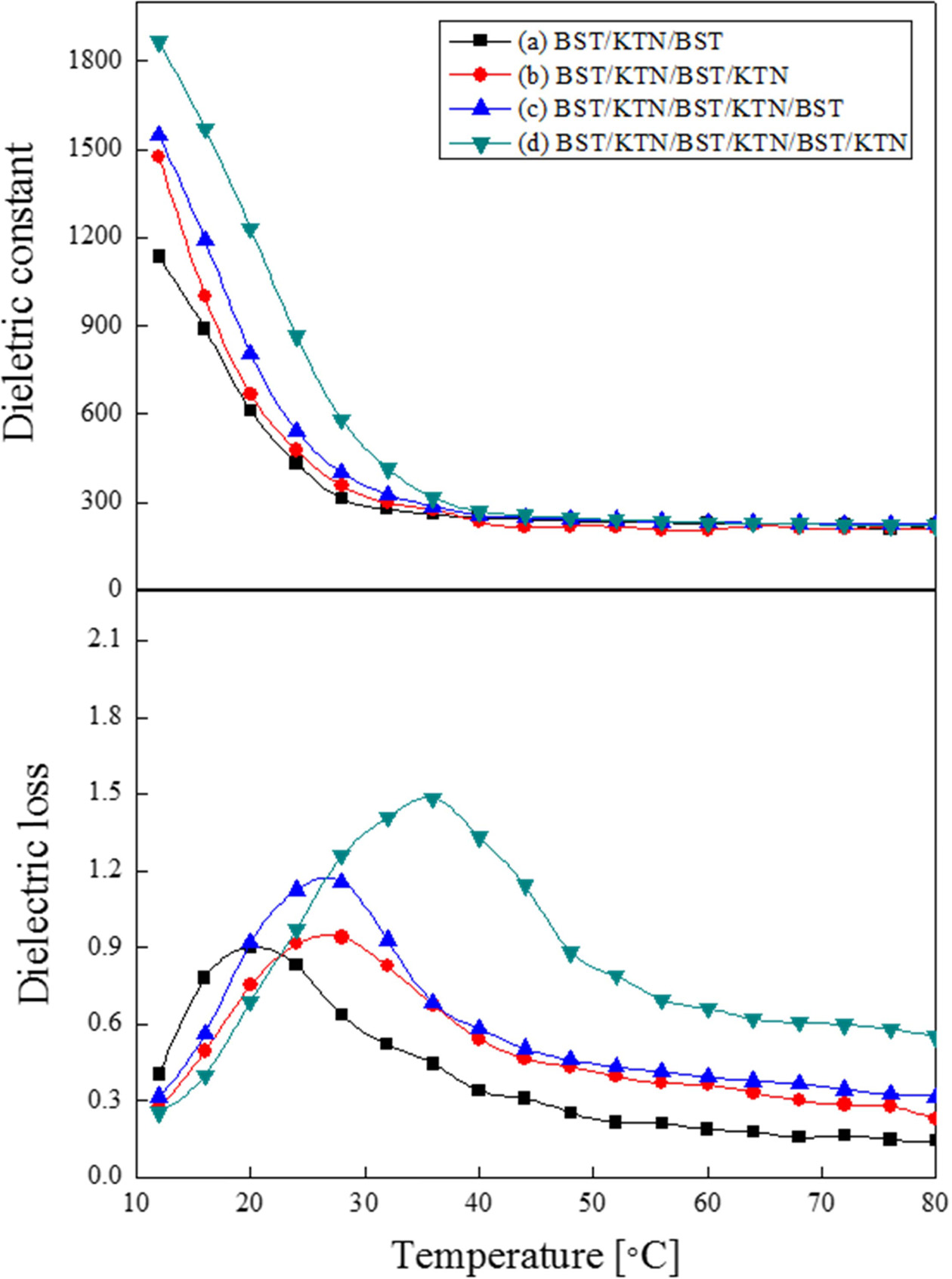

Fig. 4 shows dielectric constant and dielectric loss of BST/KTN

multilayer thin films with temperature variation.

Dielectric constant and dielectric loss increased as the

number of coatings increased. This is attributed to the formation of

interfacial polarization due to space charge between BST and KTN thin films

[17]. Also, it is considered that dielectric constant decreased with increasing

temperature in the measurement temperature range of 10~80 oC

because the phase transition tem-

peratures were located below 10 oC. Dielectric constant

and dielectric loss of the 6 coated BST/KTN multilayer thin films at 20 oC

were 1,231 and 0.69, respectively.

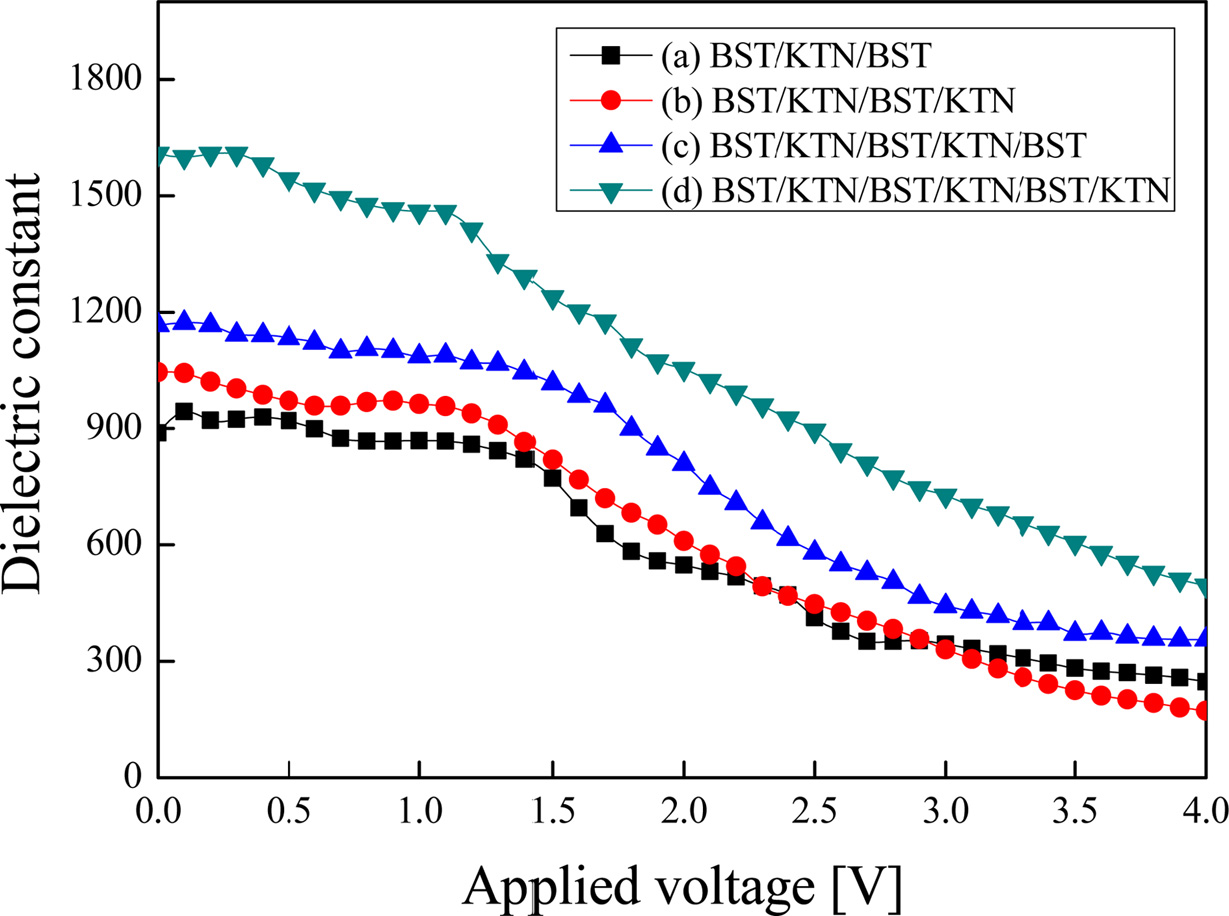

Fig. 5 shows dielectric constant of BST/KTN multilayer

thin films with DC voltage applied. Dielectric constant decreased with

increasing DC applied voltage, which is considered to be due to the suppression

of the displacement of ions [18]. As the

number of coating increased, the distribution of space charge formed between BST

thin film and KTN thin film and the dependence on DC electric field increased,

so the rate of decrease of dielectric constant according to the applied voltage

increased. The 6 coated BST/KTN multilayer thin films showed the highest change

rate of 17.3%/V.

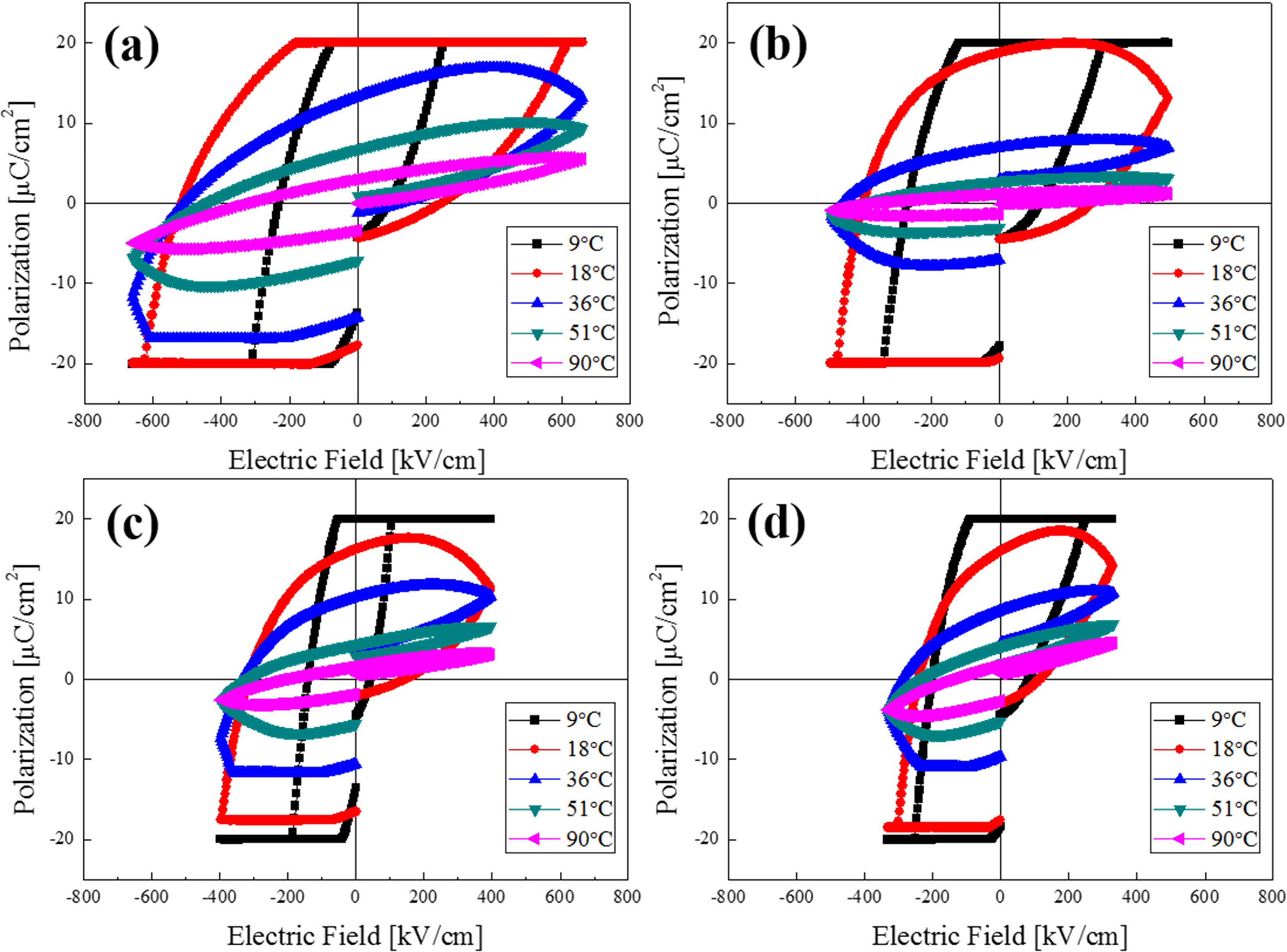

Fig. 6 shows hysteresis loops of BST/KTN multilayer

thin films with the number of coatings and temperature. As the temperature and

the number of coatings increased, remanent polarization and the coercive field

decreased. As shown in Fig. 4, because the phase transition temperature of

specimens were distributed below 10 oC, the

phase structure of BST/KTN multilayer thin films gradually changed

to the paraelectric phase as the temperature increased. Also, it is considered

that the influence of the stress formed at the interface between thin films and

Pt substrate decreased with increasing the thickness of thin films.

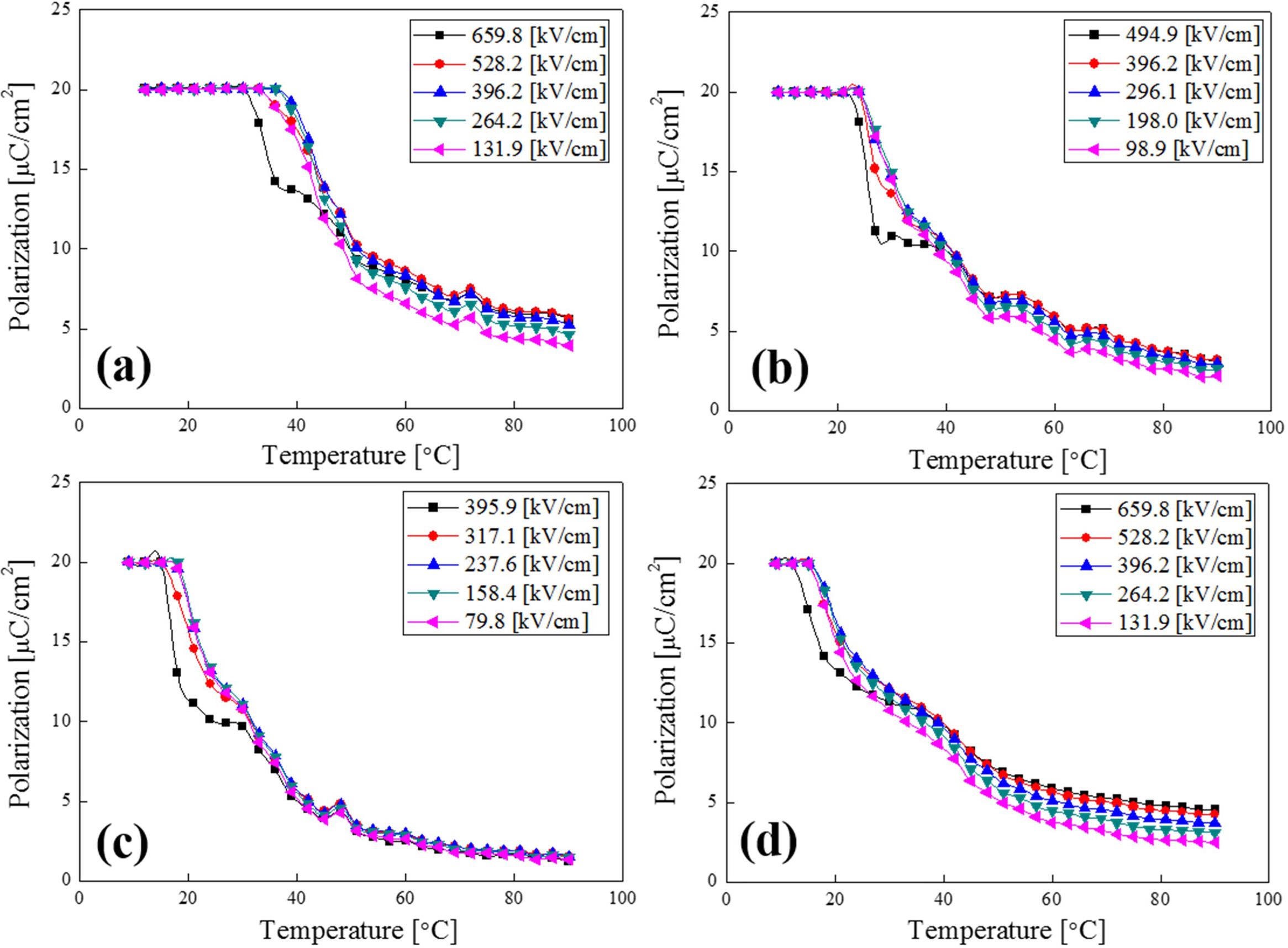

Fig. 7 shows remanent polarization of BST/KTN multilayer

thin films with temperature change. Remanent polarization

measured at 10 °C were fixed at a maximum value and

then the temperature dependent properties were shown. As the number of coatings

increased, temperatures at which remanent polarization rapidly decreased were

shifted to the lower temperature side, and the rate of change of remanent

polarization was decreased with temperature. This is because the

volume ratio of BST and KTN having a phase transition

temperature lower than room temperature increased as the number of coatings

increased, as shown in Fig. 4 and 6.

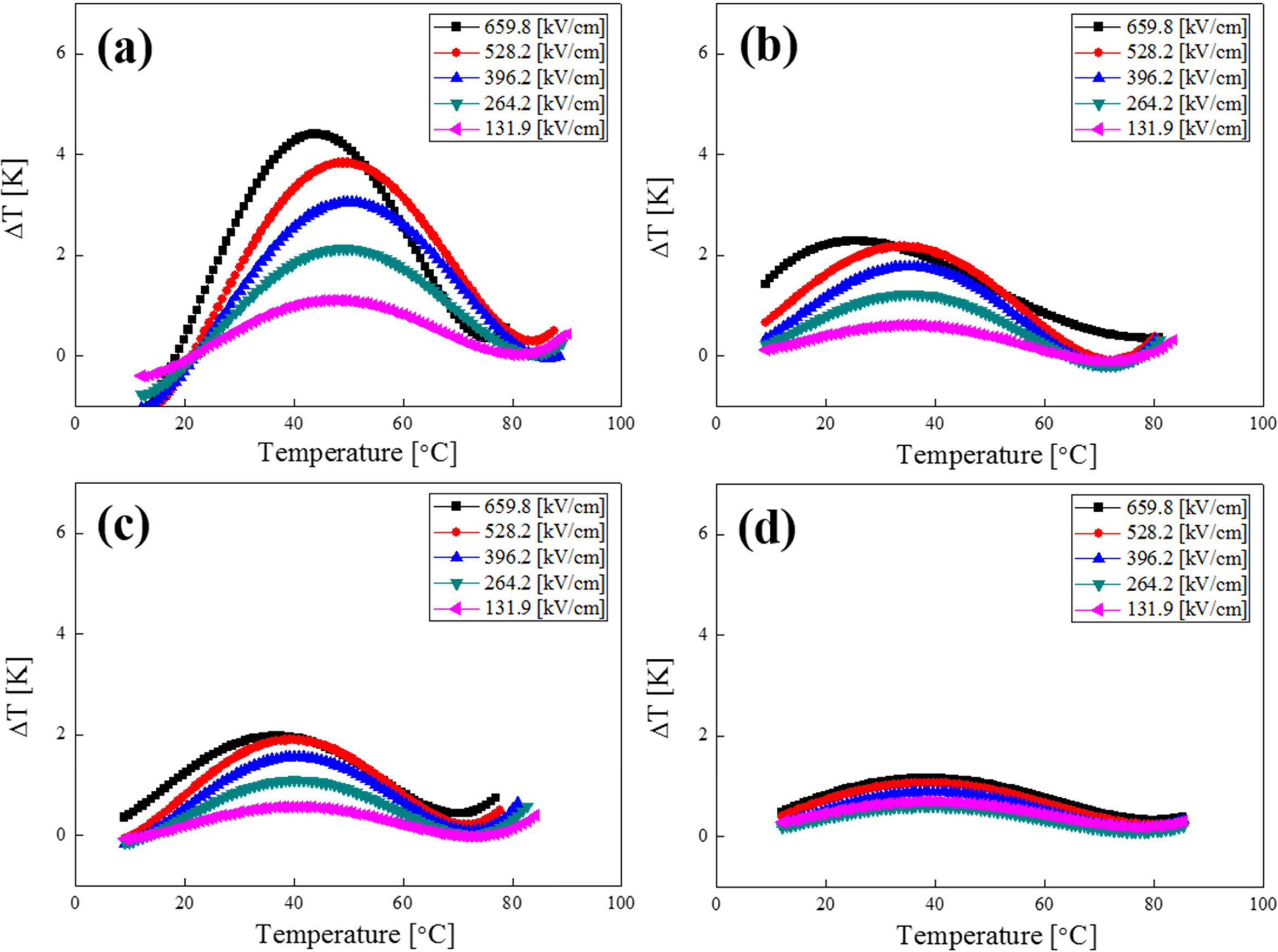

Fig. 8 shows electrocaloric

properties (ΔT) of BST/KTN multilayer thin films according to temperature and

applied voltage. Electrocaloric properties showed the highest values at the temperature where the

remanent polarization rapidly changes.

Electrocaloric properties increased with increasing the applied electric field.

This is probably due to the decrease in entropy and the temperature dependence

of dipoles arrangement as the displacement of dipoles increased when an

electric field was applied near the phase transition [19]. When the electric

field of 660 kV/cm was applied to the 3 times coated BST/KTN multilayer thin films, the

highest electrocaloric property of

4.41 oC was shown.

|

Fig. 1 X-ray diffraction patterns of BST/KTN multilayer thin films with the variation of the number of coatings. |

|

Fig. 2 Surface and cross-sectional microstructures of BST/KTN multilayer thin films with the variation of the number of coatings; (a) surface-3 times, (b) surface-4 times, (c) cross-sectional-3 times, and (d) cross-sectional-4 times. |

|

Fig. 3 Dielectric constant and dielectric loss of BST/KTN multilayer thin films with the variation of frequency. |

|

Fig. 4 Dielectric constant and dielectric loss of BST/KTN multilayer thin films with the variation of temperature. |

|

Fig. 5 Dielectric constant of BST/KTN multilayer thin films with the variation of DC voltage applied. |

|

Fig. 6 Hysteresis loops of BST/KTN multilayer thin films with the variation of the number of coatings and temperature. |

|

Fig. 7 Remanent polarization of BST/KTN multilayer thin films with the variation of temperature. |

|

Fig. 8 Electrocaloric properties (ΔT) of BST/KTN multilayer thin films with the variation of temperature and applied voltage. |

BST/KTN multilayer thin films were prepared by alternately

coating (Ba,Sr)TiO3 thin films and K(Ta,Nb)O3 thin

films. Structural and electrical properties were measured according to the

number of coatings. All specimens showed homogeneous dense polycrystalline microstructure

without secondary phase such as K2Ta2O6

pyrochlore phase. This indicates that BST thin film coated on the Pt/Ti/SiO2/Si

substrate as the seed layer for the upper layer crystallization. Dielectric

constant and dielectric loss increased with increasing the number

of coatings. It is considered that the influence on the stress formed at the

interface due to the difference in lattice constant between Pt substrate and

BST thin film was reduced. As an applied DC voltage increased, dielectric

constant decreased as the displacement of the space charge was suppressed.

Electrocaloric properties showed the highest value near the temperature at

which the remanent polarization suddenly changed, and it increased as the

applied electric field increased.

This research was supported by Basic Science Research

Program through the National Research

Foundation of Korea

(NRF) funded by the Ministry of Education (No. 2017R1D1A3 B03032164) and by the

Gyeongsang National University Fund for Professors on Sabbatical Leave, 2018

and by Korea Institute of Planning and Evaluation

for Technology in Food, Agriculture, Forestry and

Fisheries (IPET) through Agriculture, Food and Rural Affairs

Research Center Support Program, funded by Ministry

of Agriculture, Food and Rural Affairs (MAFRA)(717001-7).

- 1. H. Kishi, Y. Mizuno, and H. Chazono, Jpn. J. Appl. Phys. 42 (2003) 1-15.

-

- 2. A.S. Bhalla, R. Guo, and R. Roy, Mater. Res. Innov. 4[1] (2000) 3-26.

-

- 3. B. Liu, X. Wang, Y. Zhang, X. Lv, and Y. Yang, Ionics 20[12] (2014) 1795-1799.

-

- 4. S. Glinšek, I. Arčon, B. Malič, A. Kodre, and M. Kosec, J. Solgel. Sci. Technol. 62[1] (2012) 1-6.

-

- 5. S. Sharma, A. Kumar, V. Gupta, and M. Tomar, Vacuum 160 (2019) 233-237

-

- 6. C.M. Raghavan, J.Y. Choi, and S.S. Kim, Ceram. Int. 42[8] (2016) 9577-9582.

-

- 7. W. Hu, C. Yang, W. Zhang, G. Liu, and D. Dong, J. Solgel. Sci. Technol. 39[3] (2006) 293-298.

-

- 8. H. Sui, H. Sun, X. Liu, D. Zhou, and R. Xu, J. Eur. Ceram. Soc. 38[16] (2018) 5382-5387.

-

- 9. A.S. Mischenko, Q. Zhang, J.F. Scott, R.W. Whatmore, and N.D. Mathur, Science 311 (2006) 1270-1271.

-

- 10. M.W. Cole, C. Hubbard, E. Ngo, M. Ervin, M. Wood, and R.G. Geyer, J. Appl. Phys. 92[1] (2002) 475-483.

-

- 11. A. Nazeri, M. Kahn, B. Bender, and C. Allen, J. Am. Ceram. Soc. 194445 (1993) 2450-2454.

-

- 12. T. Ohno, M., Fujimoto, T. Ota, M. Fuji, M. Takahashi, and H. Suzuki, J. Eur. Ceram. Soc. 26[10-11] (2006) 2143-2146.

-

- 13. B. Tunaboylu, S.R. Sashital, P. Harvey, S.C. Esener, and A. Bhalla, Ferroelectrics Lett. 28[3-4] (2001) 75-84.

-

- 14. Ch. Rayssi, S. El. Kossi, J. Dhahri, and K. Khirouni, RSC Adv. 8 (2018) 17139.

-

- 15. S. Dash, R.N.P. Choudhary, P.R. Das, and A. Kumar, Canadian Journal of Physics 93 (2015) 738.

-

- 16. G. Abadias, E. Chason, J. Keckes, M. Sebastiani, G.B. Thompson, E. Barthel, G.L. Doll, C.E. Murray, C.H. Stoessel, and L. Martinu, J. Vac. Sci. Technol. A 36 (2018) 020801.

-

- 17. C.C. Wang, M. He, F. Yang, J. Wen, G.Z. Liu, and H.B. Lu, Appl. Phys. Lett. 90[19] (2007) 0-3.

-

- 18. A.E.R. Mahmoud, A.S. Afify, and S.K.S. Parashar, J. Mater. Sci.: Mater. Electron. 30[3] (2019) 2659-2668.

-

- 19. Z. Luo, D. Zhang, Y. Liu, D. Zhou, Y. Yao, C. Liu, B. Dkhil, X. Ren, and X. Lou, Appl. Phys. Lett. 105[10] (2014) 102904.

-

This Article

This Article

-

2019; 20(6): 603-608

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.603

- Received on Jul 1, 2019

- Revised on Oct 4, 2019

- Accepted on Oct 20, 2019

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Sung-Gap Lee

-

Dept. of Materials Engineering and Convergence Technology, ERI, Gyeongsang National University, Jinju 52828, Korea

Tel : +82-55-772-1687 - E-mail: lsgap@gnu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.