- Review on the self-healing concrete-approach and evaluation techniques

Sadam Hussain Jakhrani, Abdul Qudoos, Atta-ur-Rehman, Hong Gi Kim, In Kyu Jeon and Jae Suk Ryou*

Department of Civil & Environmental Engineering, Hanyang University, 222 Wangsimni-ro, Seongdong Gu, Seoul, Republic of Korea

Self-healing concrete received an attention in last few decades. This paper reviews the research conducted on self-healing in last few decades. Self-healing approaches, different types of healing agents used, incorporating procedures, and evaluation techniques are highlighted in this paper. The phenomenon of cracking and crack-healing, materials used for crack-healing and the methods and techniques employed during the process, the outcomes of experiments discussed by various researchers from their work are highlighted. From the literature review, it was concluded that the crack width sizes up to 0.1mm can be healed with autogenous self-healing mechanism, whereas, crack size up to 1mm can be healed with autonomous self-healing mechanism. It was observed that the healing efficiency was wholly dependent on the concrete exposure to corresponding environment, the type of healing agent used, procedures and techniques followed.

Keywords: Self-healing, Cracks, Self-healing approaches, Healing agents, Durability

Concrete is an artificial, man-made construction material and is the second most usable material in the world after water. It is known for its higher compressive strengths because it resists compressive forces unlike steel which strongly resist tensile forces only. Therefore; the concrete in combination with steel reinforcement is being used to resist both compressive and tensile forces. Even though it becomes more resistant to compressive and tensile loads but it faces many problems such as shrinkage and cracking at early ages and durability at later ages. Truly, there are several causes which affect the durability of reinforced concrete, some of them are water penetration, chloride penetration, sulfate attack, carbonation, alkali aggregate reaction, freeze-thaw reaction, frost etc. Water permeability of concrete also play a risky role in controlling the properties of concrete because it is directly related with the corrosion of steel reinforcement in concrete. Also a high quantity of water inside concrete make the concrete weak by making it porous and will lead to shrinkage and cracking behavior when this water is evaporated. The cracks occur in concrete are of two types; micro and macro cracks. Micro-cracks are very small in size and can be controlled at early stages by repairing or self-healing process of concrete but macro-cracks are very hard to control and leads to proper destruction to concrete structure. Micro-cracks not only allow water to go inside the structure but also allow other harmful gases and ions to ingress in concrete which initiate many weaknesses in concrete [1, 2]. The concrete structures which are in use for any purpose have to crack because of direct and indirect stresses from various sources such as, changes in atmospheric temperature and humidity, and external loadings (dead or live loads). For the serviceability and durability of structures, it is necessary to remediate crack propagation at any cost. Not all of the micro-cracks are harmful because many of them auto-heal after some time. To overcome early age cracks (micro-cracks), self-healing concrete is suggested to be made. Self-healing agents are mostly incorporated during mixing time or after crack propagation. Self-healing materials have the ability to restore the structure’s original functionality as it was before occurring of the cracks [3, 4]. Concrete structures obvious to marine environments are prominent to be attacked by harmful chloride and sulfate ions. These harmful agents cause cracks and other damages in concrete to deteriorate it. Therefore, repair and maintenance of such structures is essential to increase service life of concrete structures in such environments. Usually slag based blended cementitious materials are used in such environments to create autogenous healing in concrete to overcome early age cracks [5]. Cracking is intrinsic characteristic of cementitious materials however; these materials have the capability to heal cracks wholly by autogenous technique because when moisture or water is entrapped into cracks, the un-hydrated cement particles start hydrating which in result heal the cracks. Once the water and carbon dioxide (CO2) appear in crack surface, healing occurs due to carbonation of trickled Ca(OH)2 [6]. Cracks rise permeability of concrete which affect its durability. As the cracks progress steadily, it is very hard to determine when to overhaul them. Self-healing materials are the solutions to this because they repair cracks themselves automatically [7]. Japan Concrete Institute (JCI) defines the phenomenon of self-healing is defined as “the process of filling and sealing of cracks that automatically take place without any practical works by workers” whereas; Reunion Internationale des Laboratoires et Experts des Materiaux, Systemes de Construction et Ouvrages (RILEM) defines the self-healing as “any process by the material itself involving the recovery and hence improvement of a performance after an earlier action that had reduced performance of the material” [8]. Self-healing of concrete is the ability of concrete to repair its cracks by itself [9, 10].

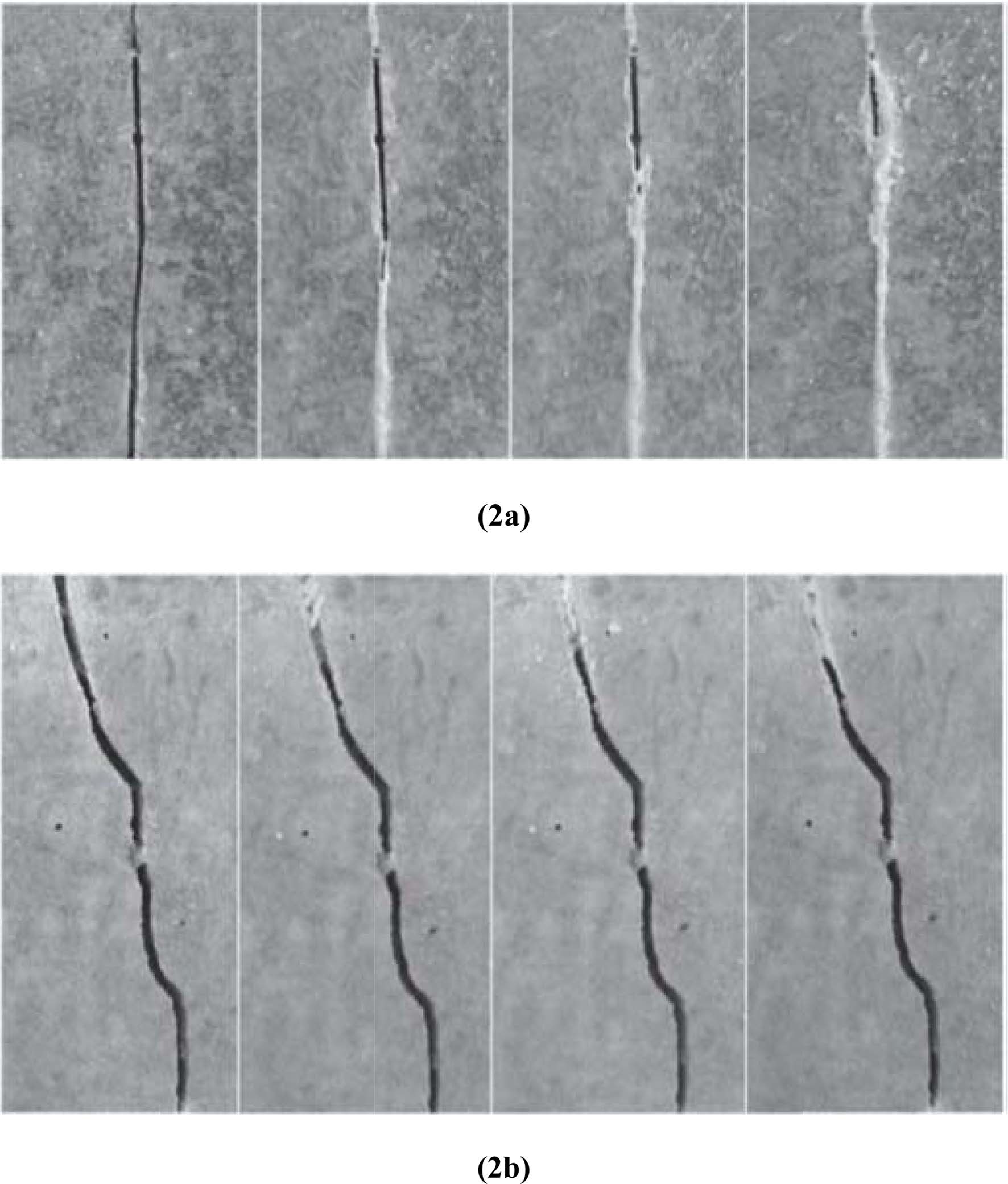

There is a vast literature on this topic, because today’s concrete is getting more interested due to its most prominent behavior of crack-healing in 21st century. Many researchers have researched and worked a lot on this topic in recent decades and many of them are still working on it to get more healable concrete. In today’s research, most of the researchers are trying to get rid of early micro-cracking which when grows in high ratios and wider then cause many problems. These micro-cracks not only allow water to go inside the structure but also allow other harmful gases and ions to ingress in concrete which initiate many weaknesses in concrete [1, 2]. Not all of the micro-cracks are harmful because many of them auto-heal after some time. To overcome early age cracks (micro-cracks), self-healing concrete is suggested to be made. Self-healing agents are mostly incorporated during mixing time or after crack propagation. Self-healing materials have the ability to restore the structure’s original functionality as it was before occurring of the cracks [3, 4]. Cracks in concrete are the key reason for a declined service life of concrete structures [11]. Bacteria-based self-healing is an auspicious solution for sustainable concrete maintenance [12]. Spore-forming alkali-resistant bacteria were used for this research work. The used bacteria (peptone and yeast) were cultivated in fluid medium comprising of the dosage of 5 g/liter and 3 g/liter of distilled water respectively. Mortar prisms were made to measure the crack-haling of specimens. Artificially cracks size (0. 1mm to 1 mm) were induced in mortar specimens as shown in Fig. 1. After the followed procedures and period, specimens were checked. The analysis of precipitation of crack-healing was analyzed by SEM, EDX and XRD. It was concluded that the crack-healing ability of concrete depends on many factors but the most prominent was crack-width size, crack sizes of not more than 0.8 mm were able to be self-healed by using bacteria-based healing agents by precipitation of calcite as shown in Fig. 2 [13].

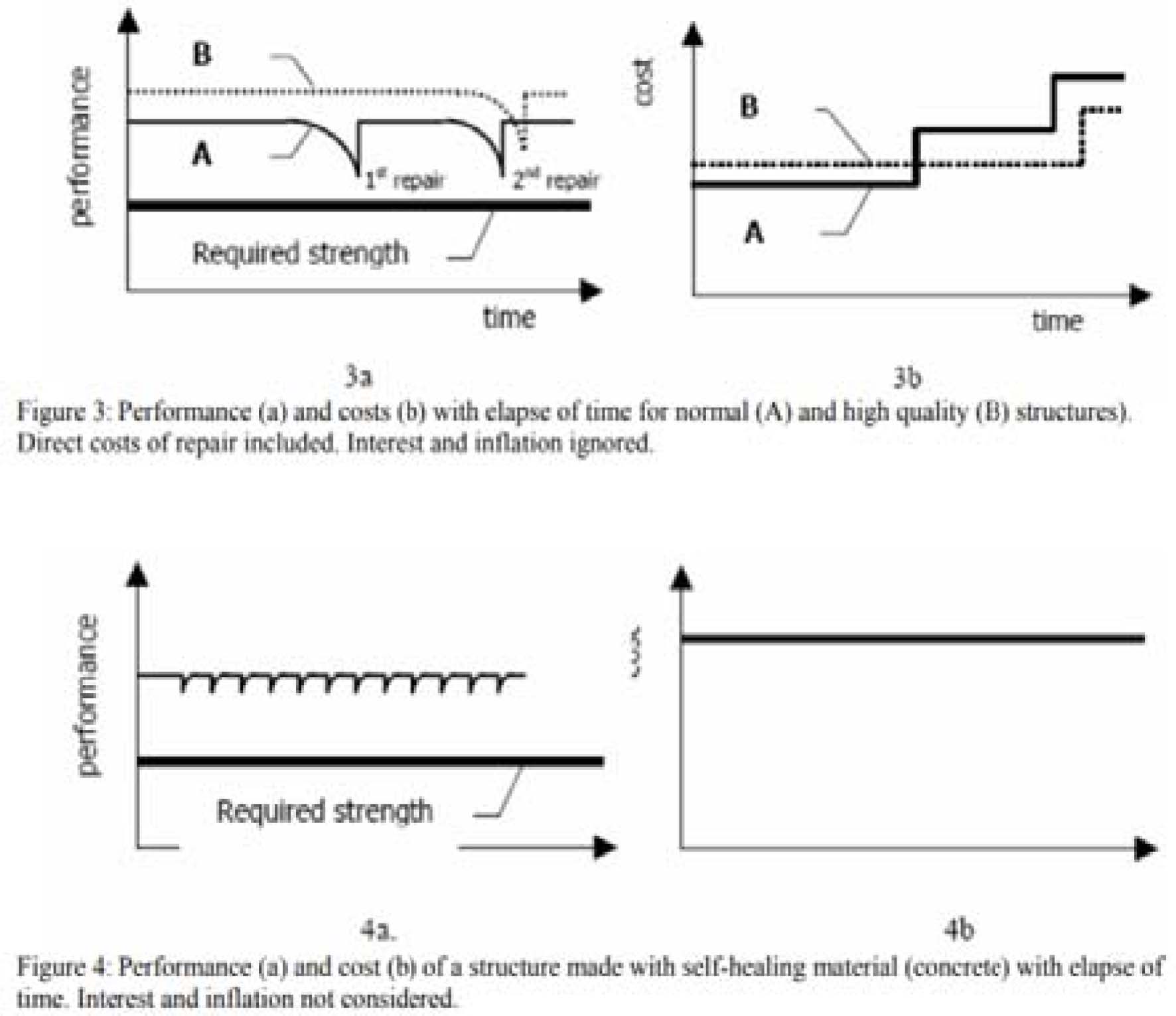

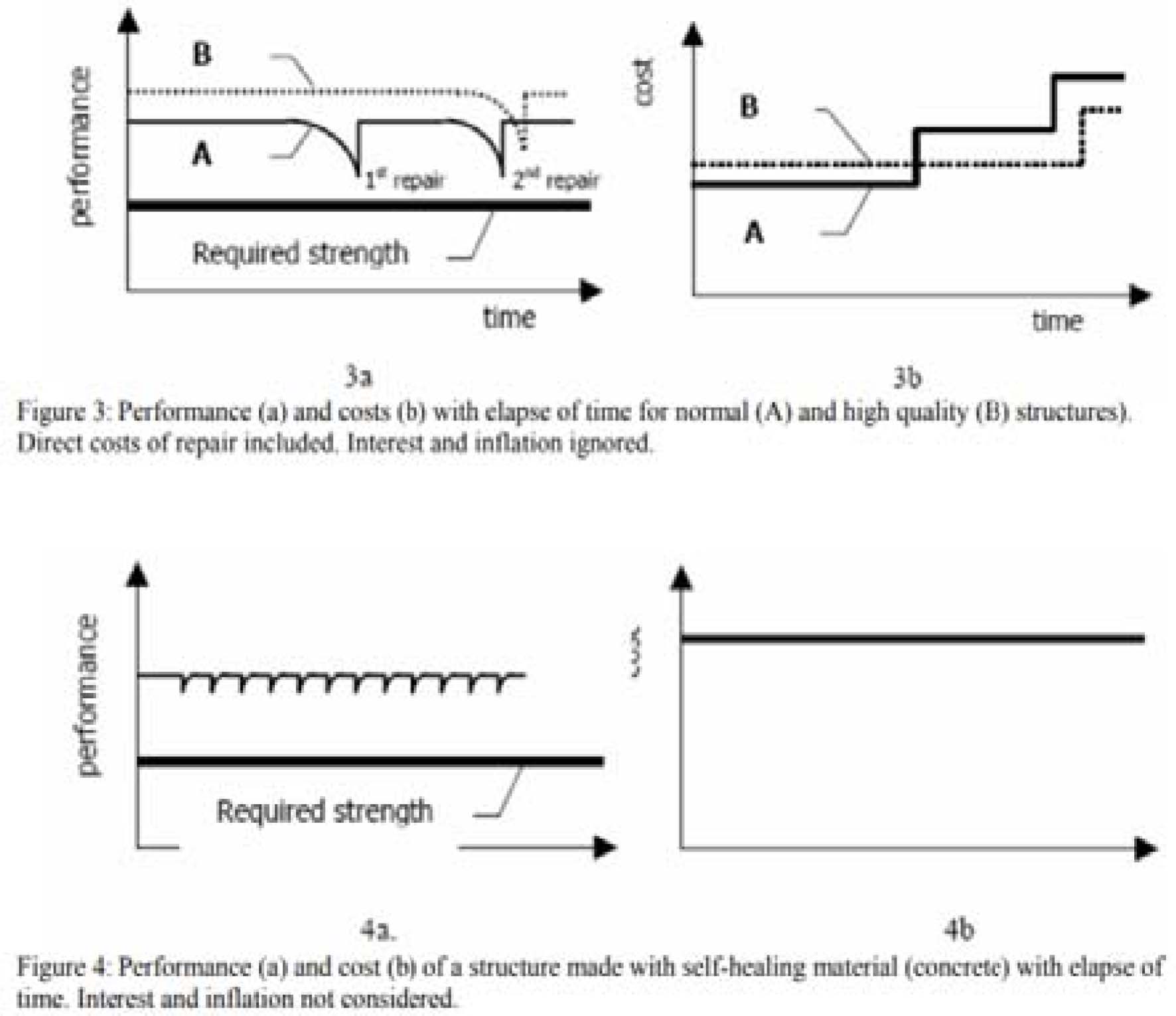

Cracks are hypothetical, and recognized to put in danger the strength, service life, stiffness and durability of reinforced concrete structures. The most common degradation source of concrete is the transport processes. The presence of cracks (micro and/or macro-cracks) will increase the passage of damaging elements into the concrete, thus resulting in the risk of degradation of concrete. The crack filling with incorporation of self-healing agent will finally contribute to better emblematic performance of concrete and reduced cost as shown in Fig. 3 and 4 [9, 10]. Self-healing concrete gives better performance than the ordinary concretes. It gives no or very less number of repairs at given strength and time as compared to conventional concrete. Fig. 3a shows the performance of normal and high quality concretes with respect to time. In Fig. 3a, the alphabet A shows the normal/conventional concrete whereas, B shows the High quality concrete. It can be seen that the concrete B requires less number of repairs than concrete A with passage of time. Similarly, Fig. 3b shows the cost of concrete with passage of time. It can be noted in Fig. 3b, the initial cost of concrete B is higher than the concrete A, but with the passage of time, this cost decreases as compared to concrete A. It concludes that concrete B requires less number of repairs or it requires no/less maintenance after made but the concrete A requires more repairs which will definitely increase repair and maintenance costs. Similarly, Fig. 4 shows the performance and cost of conventional concrete with the self-healing concrete. Fig. 4a shows the performance of conventional and self-healing concrete. In the Fig. 4a, the light zig-zag line shows the performance of conventional concrete and the bold line shows the performance of self-healing concrete. It can be observed that the conventional concrete requires many repairs at a given strength whereas the self-healing concrete does not require any repair or maintenance cost. Hence self-healing concrete gives much better performance than the conventional and high quality concretes. Fig. 4b shows the cost of conventional and self-healing concretes. The final cost is almost equal to each other at a given time. Because the initial cost of conventional concrete is very low but with passage of time, it requires repair and maintenance, labor cost and wastage of time, which indeed increases its cost whereas in case of self-healing concrete, the initial cost is very high than the conventional concrete because of material cost, but finally it requires no repair and maintenance which almost equals the final cost of both concretes. Therefore, it is recommended to use self-healing concrete to save time, energy, labor cost etc. [10].

During this study autogenous repair of cracks was studied. Cracks were produced in concrete specimen by cutting it into two halves with fixed crack-widths. Tests were examined on cutting specimens of sizes 38x13x6 mm3 concrete coupons. The surfaces of both cut specimens were matched as shown in Fig. 5. and were further studied in details. After appropriate curing dates, results were of various specimens were taken. In this case, only two types of repair/healing were recognized. First, the partial filling of concrete cracks and the second structural shear strength was completely restored. SEM and EDS analysis were also carried out, which indicated the appearance of magnesium silicate material within the crack surfaces. Carbonation was not noticed when cracks were sealed by the process autogenous healing. Also with the autogenously healed concrete, the chloride diffusion rate was not at the level which was before healing in virgin concrete. However, the water permeability and chloride ingress were blocked by filling of cracks regardless of the obtained strength [14].

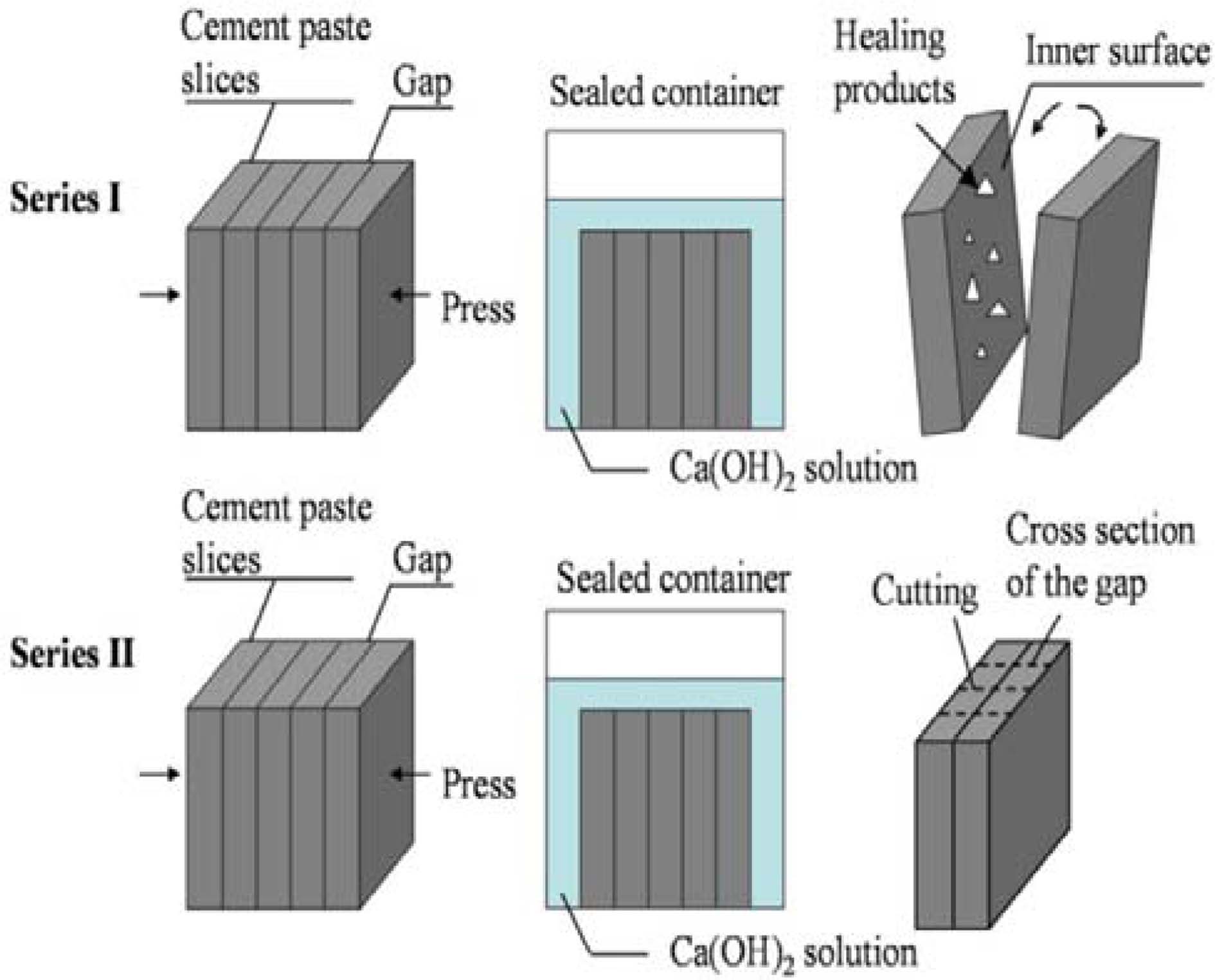

For the preparation of specimens, slag-cement pastes were made from CEM III/B 42.5 N cement type. the slag percentage (%) in cement was 66%. The calcite % in cement was observed from TGA analysis which was 3.5% and 0.3 was used as water/cement (w/c) ratio. A series of two (02) specimens were made for various tests. In this study, the healing agent used was Ca(OH)2. Two series of test samples were prepared for various tests. These specimens were prepared to check the properties of healing products formed in this process. The slag-cement pastes were first cut at the curing age of 28 days. The size of each cut specimen was 40 ´ 40 ´ 5 mm3. These cut specimens were then prudently pulverized into powder form with sand papers to assure the surfaces of slices were flat. After that, these slices were cured in healing agent Ca(OH)2 solutions under sealed conditions. Reaction products were precipitated inside the gaps of slices. After 200 hrs., these slices were separated and dried with vacuuming for 2hrs. After that these sliced surfaces were observed with SEM and the reaction products were detected by EDS analysis. The detailed schematic diagram is given in Fig. 6. The investigated properties of slag-cement pastes in this study were physio-chemical properties. The cement containing a high content of slag about 66% with saturated Ca(OH)2 solution as an activator, it was established that the reaction products formed in cracks are composed of C-S-H, ettringite, hydro-garnet and OH- hydrotalcite. It was concluded that the crack-healing phenomenon of this type of specimens was very fast in first 2days, after 2 days the process was very slow. After 10 days, crack widths of about 10 micro-meters were filled 60% [15].

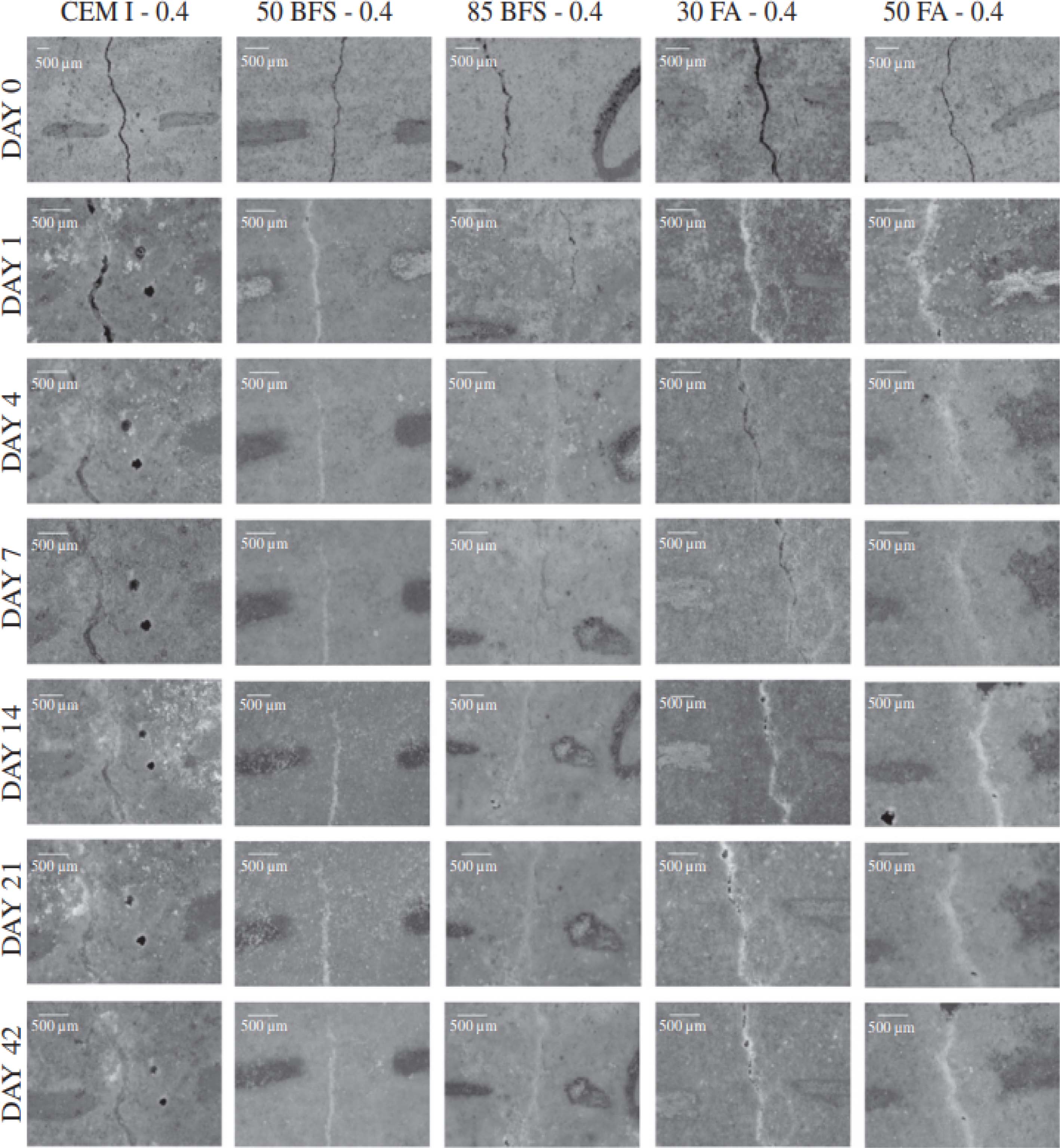

Cement pastes and mortar samples with varying binder composition, type and w/c or water/binder (w/b) ratios were prepared. In this study, three types of cements (CEM I, CEM II/B and CEM III/B) were used to make cement pastes. Cement pastes with different amount and type of cements were used to make specimens. The details about the number of mixes, mix proportions, w/b, types of binder used, size of specimens are given in [6]. After making the specimens for different tests, they were allowed to be hardened for specific time. Different types of test methods were conducted to measure the behavior of specimens accordingly. Autogenous healing was measured through microscopic investigations. At the age of 28 days of casting specimens, controlled-cracks were artificially created on the surfaces of mortar prismatic specimens. After creating cracks, they were analyzed using a stereo microscope. Subsequently, cracked specimens were immersed in water wholly to start healing process. At submergence of different days, the specimens were taken out from water and crack-healing was measured as shown in Fig. 7. From the microscopic analysis, it was concluded that the crack widths of about 0.2 mm were easily filled with CaCO3 precipitation [6].

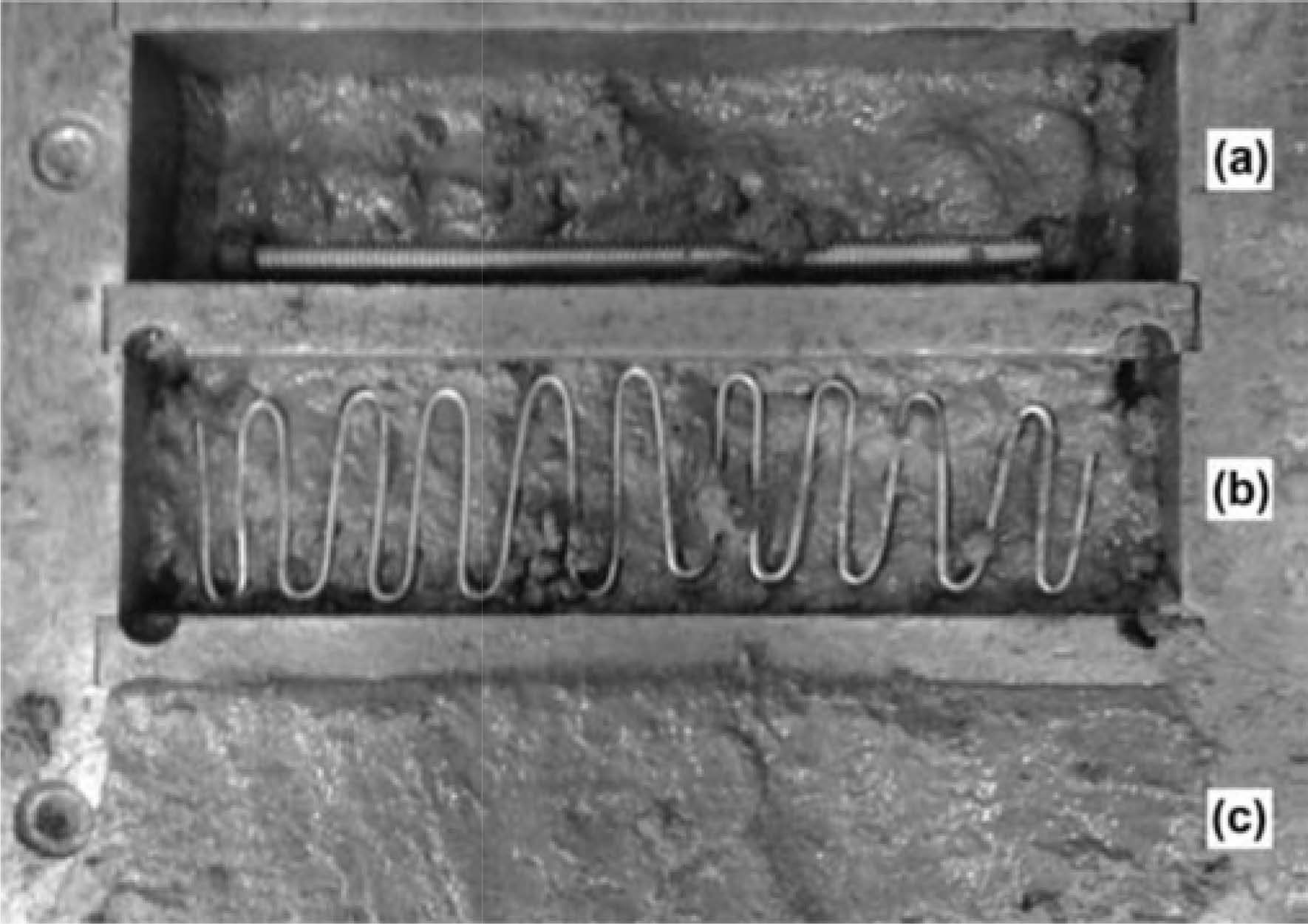

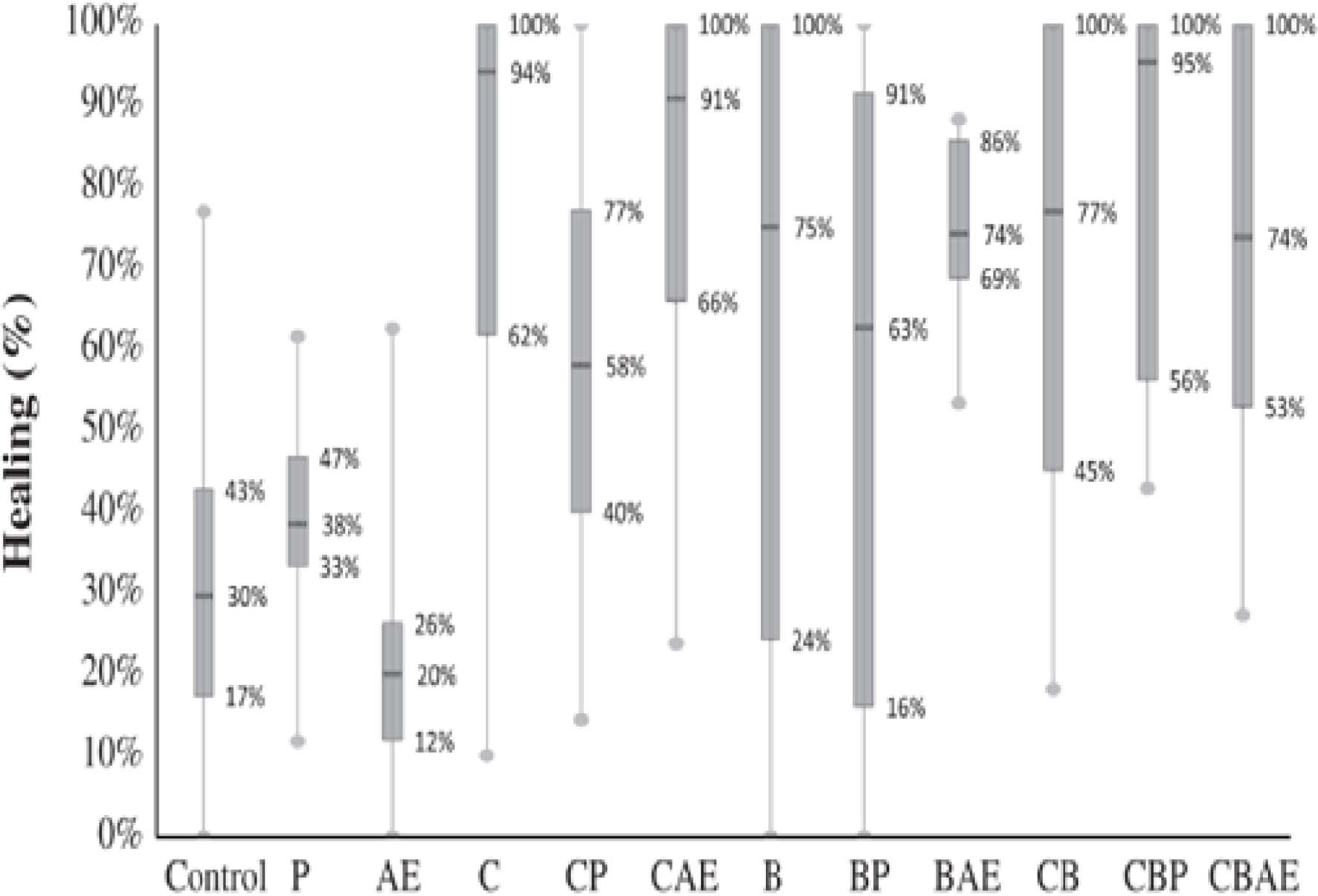

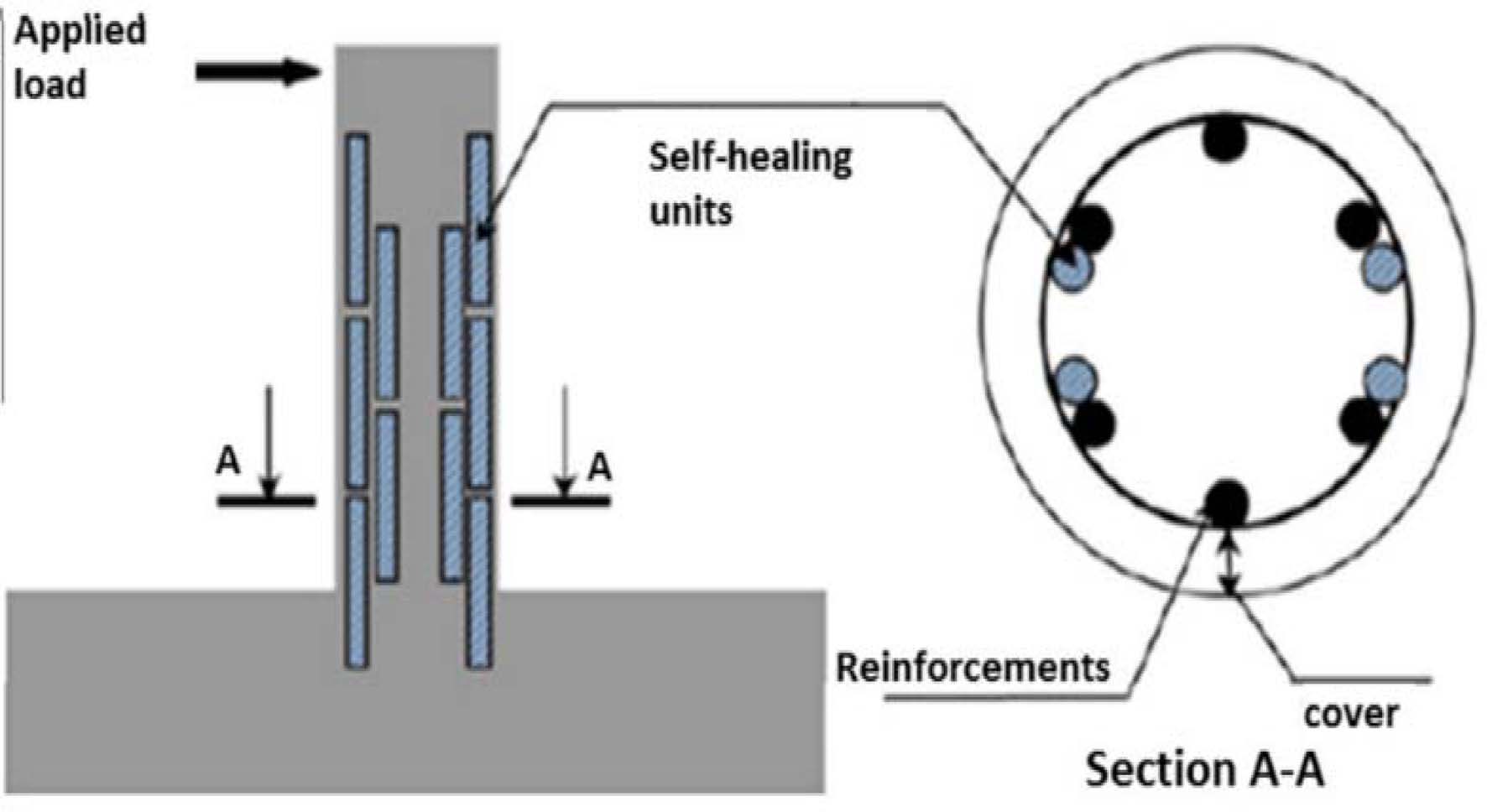

In this research, reinforced flexural mortar specimens with different types of self-healing agents and chemical admixtures were first made, then cured and cracked, and finally left submerged in water at a room temperature for 100 days to self-heal as shown in Fig. 8. The mortar samples were made with Portland cement, silica sand. and three different types of self-healing agents (1) chemical agents; namely calcium lactate solution (C), (2) biological agent, bacteria and yeast extract solution (B), and both combined chemical and biological agents (CB). Each type of healing agent has further three types as shown in Table 1 of [7]. Crack-healing performance is shown in Fig. 9. It was observed from the results of image analysis, that the all healing-agents increased the healing ability of respective specimens. In addition, the specimens containing combine self-healing agents gave better results than the others. From the regression analysis it was established that the chemical self-healing agents were more prominent than the biological healing agents. Furthermore, it was seen that the chemical admixtures have no adverse effect on healing agents so they can be used with healing agents. Also, the thermal analysis of hent specimens after 100 days with an initial crack size ranging from 0.08 mm to 0.22 mm [7].

ealing agents also proved the presence of CaCO3 in cracks. Finally, it was concluded that the crack sizes between 0.08mm to 0.22mm can be healed by using chemical, biological or the combination of both healing agents [7].

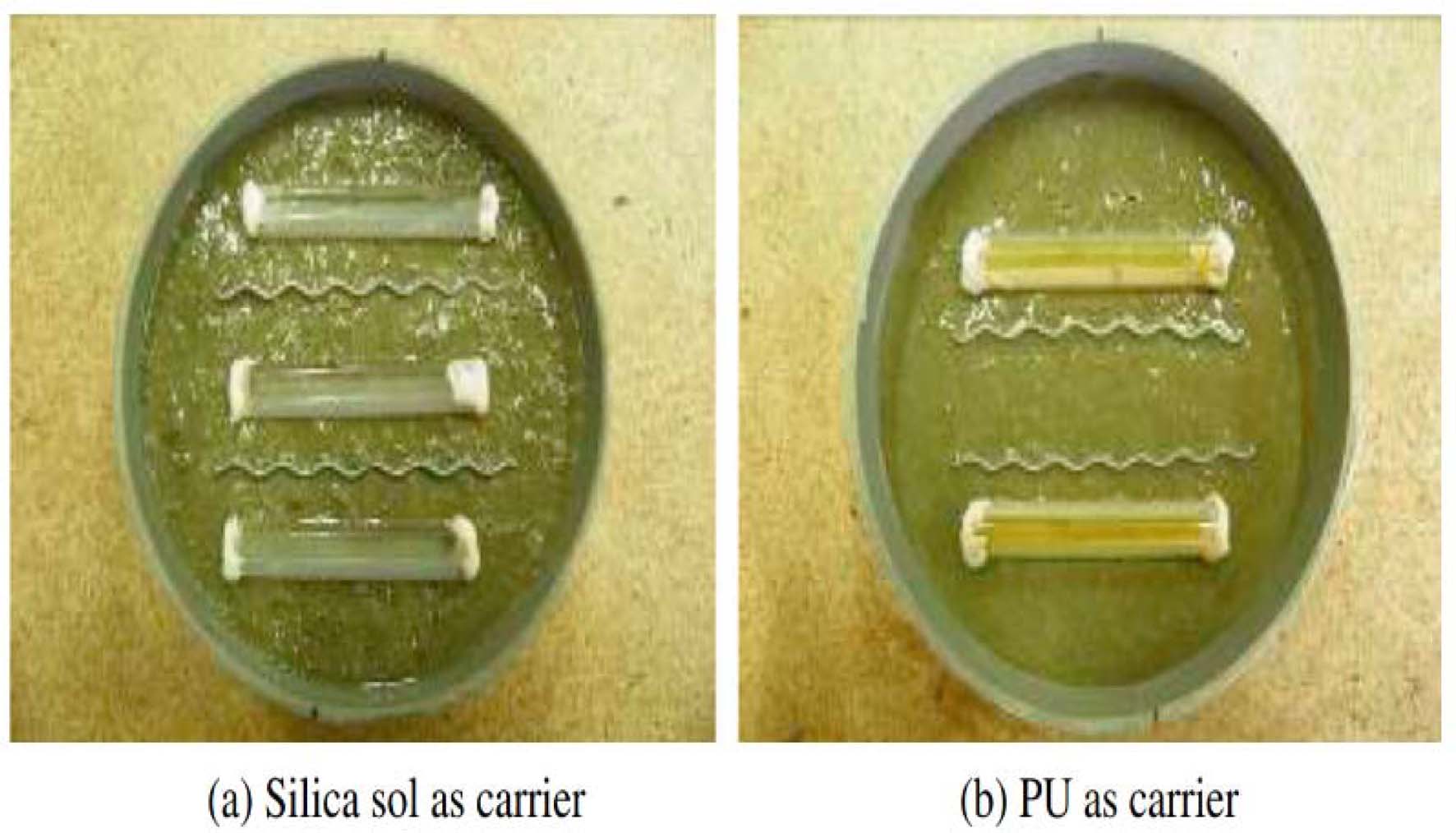

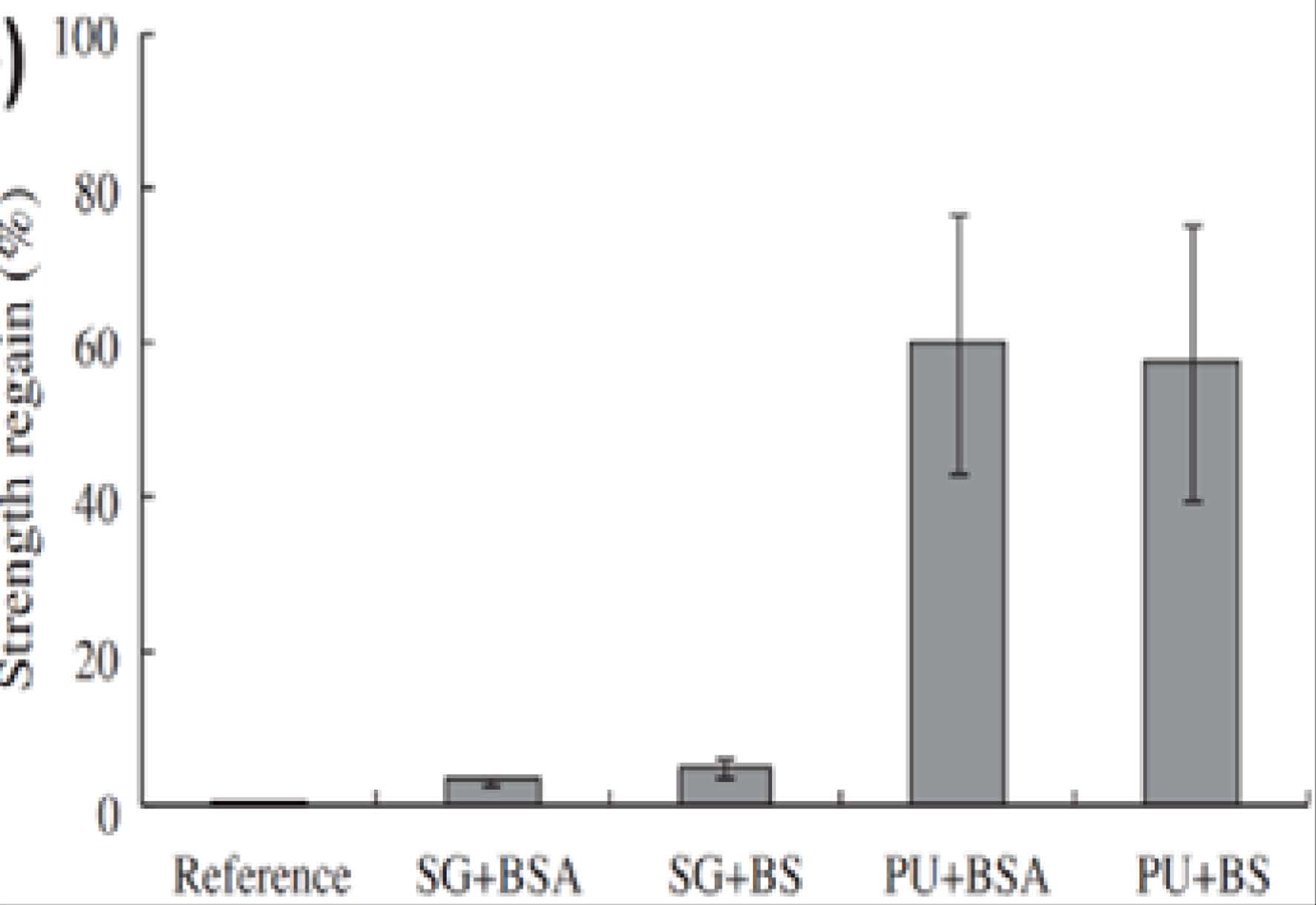

In this study, the used bacterial strain was B. sphaericus LMG 22,557. This used strain had a high urease activity about (40 mM urea hydrolyzed OD-1 h-1), long existence time and can produce CaCO3 in a simple and controlled way. The medium used to grow B. sphaericus comprised of yeast extract and urea. The yeast extract medium was first autoclaved for about 20 minutes at 120 ℃ and the urea solution was added which was pasteurized by means of filtration through a hygienic 0.22 lm Millipore filter. The final concentrations of both yeast extract and urea were 20 g/L. Silica gel and/or polyurethane was used as the carrier for protecting the bacteria as shown in Fig. 10. Investigational results revealed that the silica gel immobilized bacteria showed a higher activity as compared to polyurethane immobilized bacteria, and hence, more CaCO3 precipitated in silica gel (25% by mass) than in polyurethane (11% by mass) based on TGA analysis. However, healing of cracked mortar specimens through polyurethane immobilized bacteria had a higher strength regain up to (60%) and lower water permeability coefficient (10-10-10-11 m/s), as matched with the specimens healed by silica gel immobilized bacteria which presented a strength regain of only 5% and a water permeability coefficient of (10-7-10-9 m/s). Finally, it was established from the results that the polyurethane immobilized bacteria have more potential to be used as a carrier for self-healing of concrete [11].

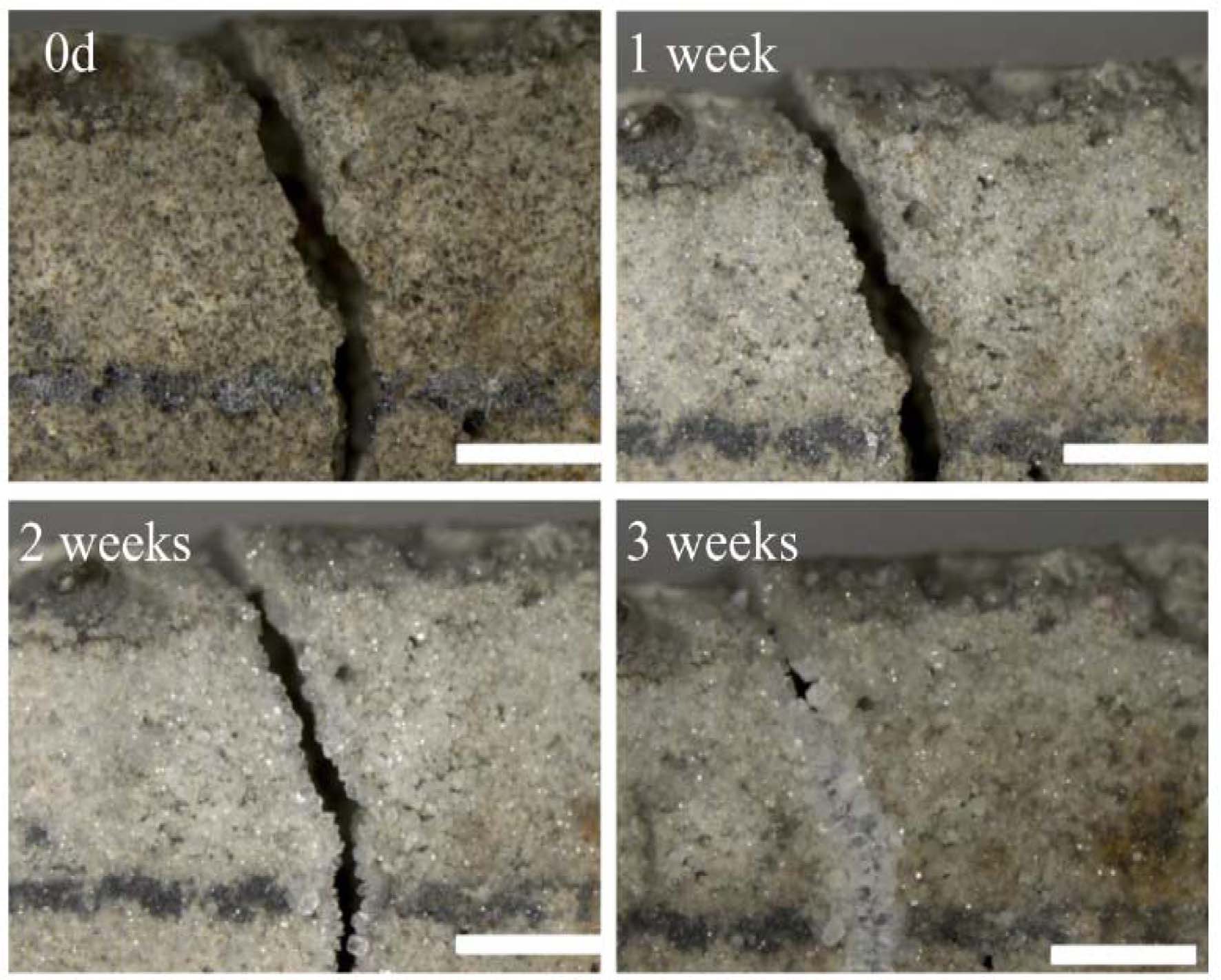

From their study, authors found concluded that the specimens containing hydrogel-encapsulated spores have healed cracks of widths 0.5 mm completely whereas, other specimens containing non-bacterial series have just healed the cracks of size 0-0.3 mm [12]. In this study authors used microcapsules to encapsulate bacterial spores for self-healing of concrete. The complete process was confirmed by SEM analysis. The outcomes of the experiments showed that the specimens contained bio-microcapsules in broken form had higher healing capability (up to 80%) as compared to those which did not contain any bacteria which had healing capacity (up to 50%). The maximum crack width which was healed in the specimens containing bacteria was 0.97mm as shown in Fig. 11 [16].

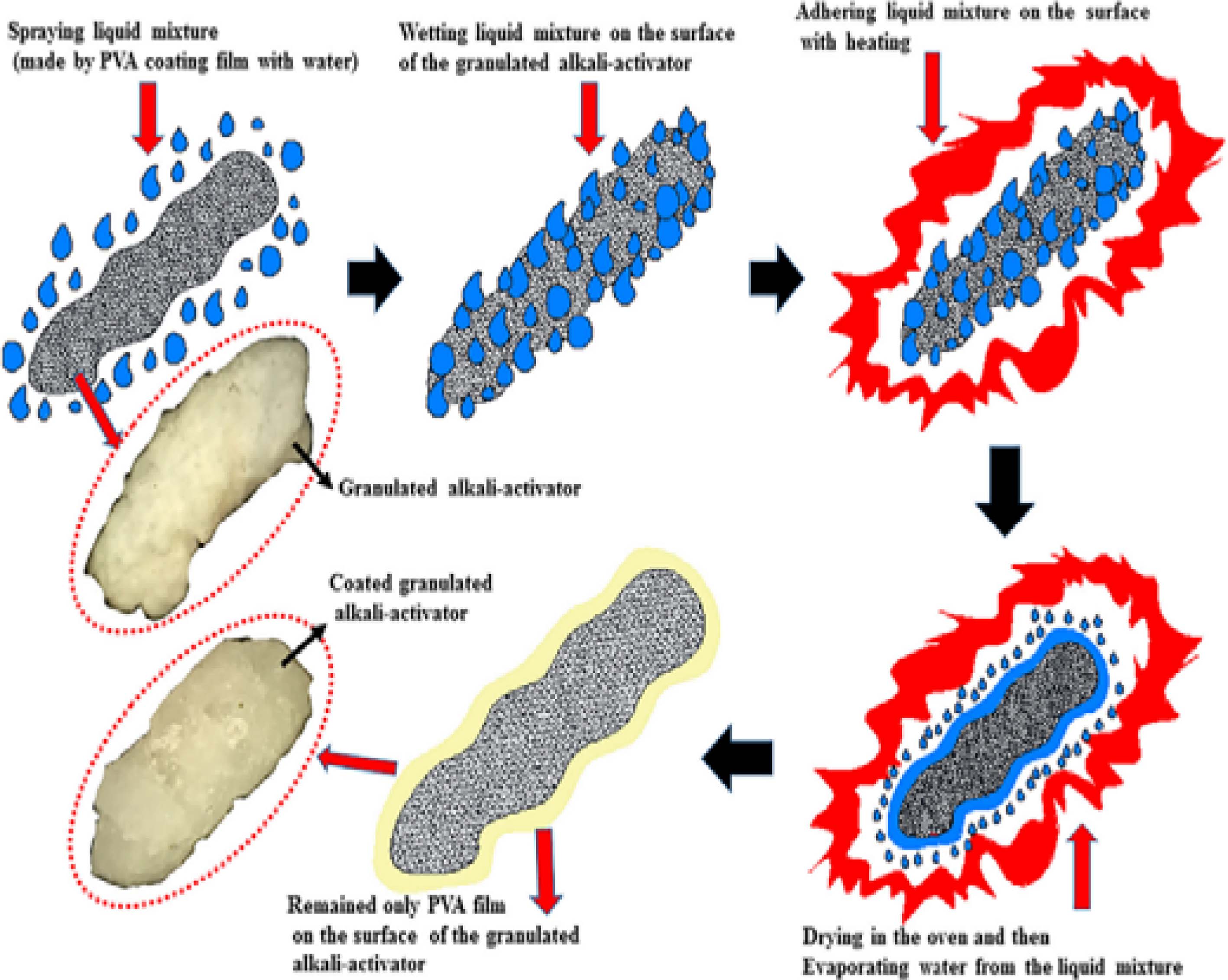

Portland cement confirming ASTM C150 and slag were used as primary binding materials, natural sand with fineness modulus (F.M) 2.65 was used as fine aggregate and Ca(OH)2 and Na2SO4 were used as activators in this research. By following an appropriate method to get a healing agent, firstly, the activators were granulated in granulation machine and then a solution of ethanol and water with 10:1 was mixed with granules to make a paste. This paste was allowed to dry at 60 ℃ in oven. After that, dried specimen was obtained and that was coated with Poly vinyl alcohol (PVA) film with pan-coating technique to protect activators during mixing as shown in Fig. 12. It was concluded from the experiment results that the specimens which did not contain any granulated activators did not show any sign of healing till 60 days. The specimens containing Ca(OH)2 granules gave better results than the specimens containing Na2SO4 specimens. It was established from the outcomes of the research that the healing products were C-S-H, ettringite, brucite, calcite, gypsum and calcium chloride (CaCl2) [5].

|

Fig. 1 Cracks formed on prismatic specimens by embedded method [13]. |

|

Fig. 2 Surface images of self-healed mortar specimens with different crack widths (2a) crack width initially 0.3 mm and (2b) initial crack width 0.8 mm [13]. |

|

Fig. 3 The performance and cost analysis of normal, high quality and self-healing concrete [10]. |

|

Fig. 4 The performance and cost analysis of normal, high quality and self-healing concrete [10]. |

|

Fig. 5 Close-up of concrete test coupon with each other [14]. |

|

Fig. 6 Schematic diagram of specimens along with two series [15]. |

|

Fig. 7 Autogenous crack-healing of specimens with passage of time [6]. |

|

Fig. 8 Reinforcement used in mortar specimens (a) flexural reinforcement, (b) shear reinforcement and (c) surface finish [7]. |

|

Fig. 9 Self-healing of different specimens after 100 days with an initial crack size ranging from 0.08 mm to 0.22 mm [7]. |

|

Fig. 10 Carriers for bacteria (10a) shows the silica gel as a carrier for protecting bacteria (b) shows the polyurethane as a carrier for bacteria [11]. |

|

Fig. 11 Self-Healing of bio-encapsulated concrete specimen up to 3-week period [16]. |

|

Fig. 12 Procedure for coating the granules [5]. |

There are two approaches of self-healing in concrete which are established on the approaches of healing; autogenous healing and autonomous healing [17]. The mechanism of autogenous and autonomous healing is carried out with many ways like by natural methods or by using artificial methods i.e. chemical or biological materials or processes [18]. Self-healing process is categorized in two different ways i.e. natural healing and artificial healing. Process of natural healing happens is done in case of autogenous healing of concrete whereas process of artificial healing is done in autonomous healing according to their definitions. Cracks in concrete are the major reasons for a diminished service life of concrete. Therefore, it is prudent and efficient to control or confine the expansion of early age small cracks at the time when they appear. Because it is best way to restrict them than to repair them. To do so, the best way is to add healing materials to the concrete at time of mixing so that they work themselves automatically when small cracks appear at the surface of concrete [11].

According to JCI, autogenous-healing is defined as “a natural process of filling and sealing of cracks without any external operations”. Whereas; RILEM defined the term autogenic healing as “the recovery process uses materials components that could otherwise also be present when not specifically designed for self-healing own generic materials”. Autogenous healing is related with the phenomenon of self-healing which results from physical and/or chemical composition of cementitious materials in concrete itself. With the phenomenon of autogenous healing, only the crack widths up to of 0.2 mm to 0.3 mm are healed [19-22]. Autogenous self-crack-healing is related with the healing process occurring naturally. Autogenous healing mainly depends on the (1) formation of calcium carbonate (CaCO3) from calcium hydroxide Ca(OH)2, (2) Blocking cracks by impurities/debris already in mixing water (3) hydration of unreacted cementitious materials in presence of moisture and (4) furthermore swelling of hydrated cementitious particles in concrete as shown in Fig. 13 [22].

Autogenous self-healing is done naturally by physical, chemical and mechanical methods. Physically, it occurs as in form of swelling or expansion of hydrated cement paste near the crack faces. Chemically, it occurs in two ways, first in form of continued hydration of binder which only happens when the hydration is not completed at early ages due to absence of extra water for complete hydration, and secondly the formation of CaCO3 and appearance of crystals on the crack faces this happens when calcium ions from pore water of concrete react with carbonate ions of moisture/water in cracks combines calcium and carbonates ions together and form CaCO3 and finally it precipitates in the crack. This mechanism/reaction depends on the pH, temperature and concentration of reactants. Mechanically, it occurs in form of fine particles from moisture or water comes from other external sources to crack or in form of broken pieces/particles from concrete [8]. Autogenous healing can only occur when concrete repairs hair-line cracks by itself through reaction with water/moisture available in it [14]. Autogenous healing can happen in different environments, ranging from under-water immersion to cyclic wet–dry experiences. These conditions are real-world conditions for many systems, mainly for transportation infrastructure. Therefore, in these situations self-healing can easily be contented. Secondly, for autogenous self-healing, chemical species with adequate concentrations are needed which is readily satisfied. The third criteria for autogenous healing is the crack width of size < 150 μm and preferably below 50μm which can easily be self-healed [23]. The concrete specimens containing slag-cement with high % of slag in it, have high healing ability than the cements which contain no slag [16]. The effect autogenous crack-healing was investigated by using substitute binding materials, such as slag and fly ash. It is noticeable that the slag and fly ash react slower than cement thus in result more unreacted binding material remains in hardened matrix which allows crack-healing with additional hydration. CaCO3 precipitation was calculated with the help of microscopic analysis. It was noticed that the replacement of cement with slag/fly ash did not increase crystal precipitation. In addition, it was revealed that the smaller cracks closed entirely and sooner than larger cracks. Also there was no difference in strength gain of samples. Generally, it was concluded from the study that the cement replacement with slag and fly ash improves the autogenous-healing by increasing later/further hydration [6].

|

Fig. 13 Mechanism of autogenous healing (a) formation of CaCO3 from Ca(OH)2, (b) settlement of loose cement particles and debris in presence of water, (c) late hydration of unhydrated cement particles, (d) excess swelling of hydrated cementitious matrix [22]. |

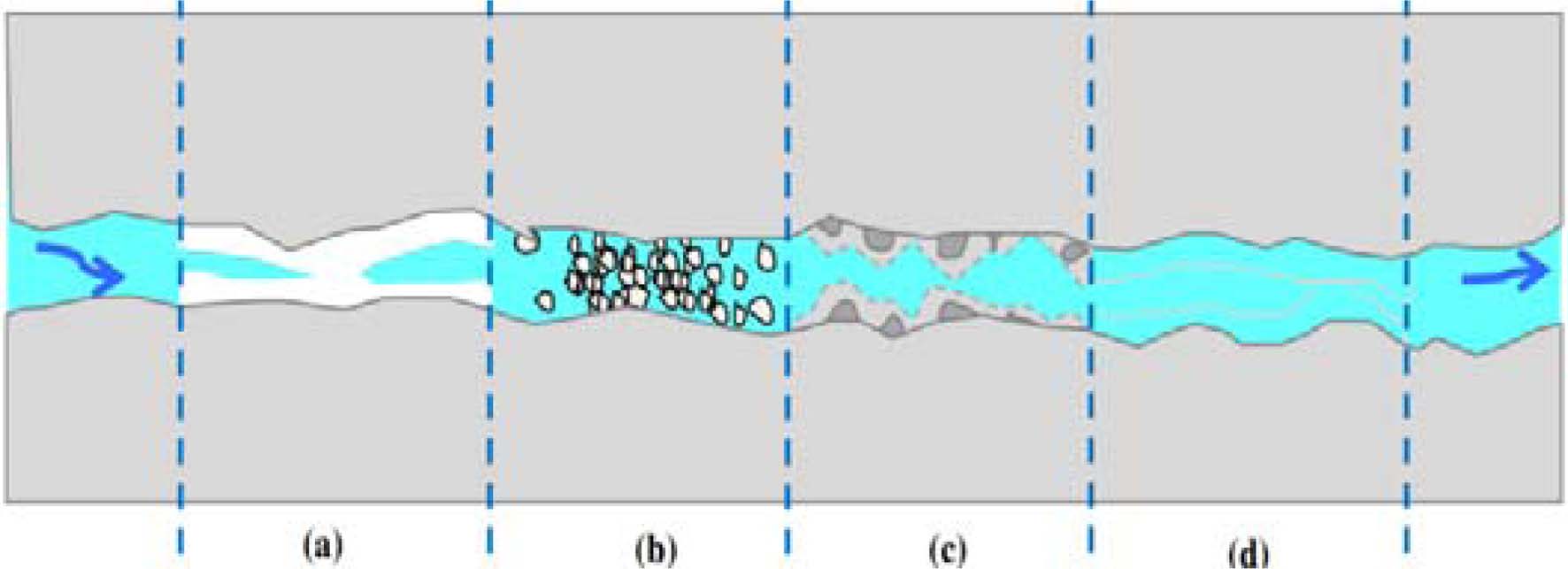

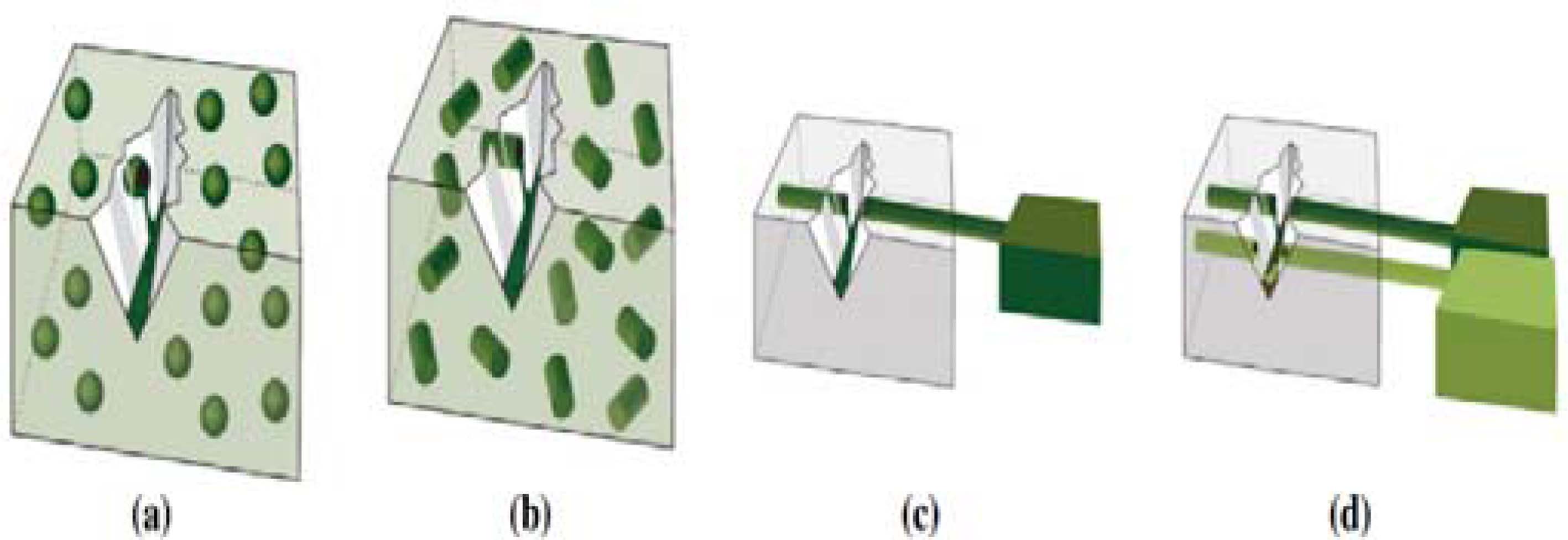

JCI defines autonomous healing as “involuntary healing of cracks that are provided by admixtures”. Whereas; RILEM states the definition autonomous healing as “the recovery process uses materials components that would otherwise not be found in the material”. The concrete is said to be autonomous healed when this mechanism is done artificially by using some external agents such as biological/chemical/mineral agents in various forms [10, 24-32]. Autonomous healing of concrete is named to concrete in which healing mechanism is artificially stimulated in the matrix with some chemical/biological materials or agents externally. External agents can be used in form of spherical/cylindrical capsules or by single-/multi-channel tubular network. A short mechanism of autonomous healing is given Fig. 14 [33].

Autonomous crack-healing is related with the artificial process of healing. Artificially crack-healing occurs in form of biological and chemical processes. Biologically it occurs in form of precipitation of CaCO3 and polymorphic iron-aluminum-silicates. In these cases, precipitation reactions are caused by fungi and bacteria [28-30]. Chemically self-healing is caused by passive and active modes. With passive mode methods, capsules and shallow pipettes are used and with active mode vascular networks with supply glue are used [10, 24, 32]. Super absorbent polymers (SAPs), mineral admixtures, microbial induced carbonate precipitation (MICP) and textile reinforced concrete are the artificial processes to be used in autonomous healing process of concrete [8].

|

Fig. 14 Mechanism of Autonomous healing (a) round capsules, (b) tubular capsules, (c) single-channel tubular network, (d) multi-channel tubular networks [33]. |

As found in previous studies, self-healing agents can be applied in concrete by two methods: Direct application and Encapsulation. Direct application of healing agents in concrete is done by either incorporating bacteria in light weight aggregates (LWA) or in in graphite Nano-platelets (GNP) whereas the encapsulation method is done by mixing LWAs in bacteria solution and then their encapsulation in a polymer based coating layer for improving the self-healing performance of concrete [34-36]. It was found that the expansive agents like, mineral admixtures, hollow fibers, polymers, micro-organisms and micro-encapsulation are enthusiastic for developing self-healing phenomenon in concrete [24]. Furthermore, chemical admixtures, geo-materials and CaCO3 precipitating micro-organisms, concrete containing dissolved salts of calcium and magnesium were also found to be the methods for healing of concrete cracks [37-39]. Moreover, synthetic fibers and cementitious materials separately and reinforced with each other were also found to be healing materials in concrete [40, 41]. Using engineered cementitious materials with and without lime stone powder were also found to be promising material for self-healing [42, 43]. Crack widths of <0.06 mm can easily be healed naturally [14, 23], crack width sizes <0.138 mm can be healed by using polymers, crack widths <0.2 mm can be healed by using SCMs [6, 15], crack sizes <0.22 mm can be healed by using chemical and other biological methods and by bacteria and encapsulations, crack width size up to 0.97mm can be healed [11, 12, 16, 44].

CaCO3 is precipitated by using the bacteria. A large number of bacteria domains are found in literature [45-55] to produce self-healing concretes. The selected bacteria have to face the problem of high pH, temperature and lack of available water in concrete after its hardening. This will lead to improper growth of mesophilic micro-organisms in these circumstances. To overcome this problem [31], used thermophilic bacteria to design concrete. During hydrolysis process of urea, photosynthesis and sulfate reduction, microbial calcium carbonate can be precipitated as a by-product [56]. CaCO3 can be found in its three precipitated forms of mineral crystals in shape of calcite, vaterite and aragonite whereas, only calcite is of superior attention in self-healing concretes [57]. There are several factors which affect the precipitation rate of biological calcite such as concentration of inorganic carbon and calcium ions, pH and presence of nucleation sites [58]. CaCO3 precipitation on concrete surface can reduce the permeability of capillary water uptake and gases. The most used methods for precipitating CaCO3 are ammonification, sulfate reduction, anaerobic sulfide oxidation, denitrification and photosynthesis [46, 47]. XRD and SEM analysis can be used for detecting biological precipitation of calcite crystals [59].

Incorporation of mineral admixtures in concrete affect the hydration process, material characteristics and the self-healing potential of concrete [36]. The cementitious and pozzolanic reaction of mineral admixtures i.e. Fly ash (F.A), granulated blast furnace slag (GBFS), silica fume (S.F), calcined clay etc. can lead to delayed and continuous hydration of cement particles for long-term calcium-silicate-hydrate (C-S-H) development. It was observed that the hydration process of binders was very low in first few weeks due to the non-reactivity of mineral admixtures in early ages. For that reason, alkali activators, alkaline solution, high curing temperatures and accelerators were used accelerate the rate of hydration for quick early healing of concrete [60]. Concretes made with F.A and GBFS, ionic solutions were used for faster hydration reaction [15, 61]. Autogenous healing was noted to be continuous when mineral admixtures were added in concrete. Autogenous healing of concrete was observed when cement was partially replaced by GBFS and F.A. [6, 11, 61].

SAPs are synthetic cross-linked homo-polymers with ability to absorb high capacity of fluids. The nature of swelling capability depends on nature of monomers and the density of cross-linking [62]. SAPs has two major functions in concrete, first of all, when it is used in concrete, it takes up mixing water during mixing and after setting and hardening it starts shrinking which in result leave small macro sized pores in concrete [63]. These pores are considered to be the weak points in matrix [64], which allow the phenomenon of cracking in matrix [65]. However, these macro-pores can be the reason of reduction in concrete strength but using SAPs as internal curing agent can further allow hydration of cement which can increase the final efficiency of matrix which is finally dependent on the type of SAPs used, its amount/dosage, particle shape and size, w/c ratio of mix and mixing techniques etc. [66-70]. Despite the concerns discussed above, mixes with high w/c and high SAP content may affect the mechanical properties. Research study [71, 72] showed that the early swelling of SAPs can be overcome by coating the SAPs by Wurster process.

The second purpose of SAPs in concrete is self-sealing of cracks once crack occurred/appeared. The crack-healing with the use of SAPs depend upon the appeared crack width. SAPs can close cracks of size < 0.14 mm whereas the SAPs in combination with fibers can easily heal the cracks sizes of 0.3 mm to 0.5 mm [73, 74]. This self-crack-sealing is due to swelling of SAPs in presence of moisture or water [64, 70, 75]. This moisture or water absorbed by SAPs can come from itself because of available water inside in it during mixing or can be extracted from humid environment. The self-crack-sealing results in formation of C-S-H and to the crystallization of CaCO3 [76-78].

JCI and RILEM included the non-absorbent polymers (polymer modified/cement concrete) in the category of engineered self-healing materials. It was stated that the polymer and cement creat a vast network by cooperation of these binding materials with adhesion and results in enhancement of flexural and tensile strengths and leads to self-healing of concrete. Like SAPs, non-absorbent polymers can only be beneficial as self-healing material when the selection of polymer type, dosage,w/b ratio, type of binder is done properly. Some researchers found that ethylene venyl acetate and epoxy resin behave as self-healing materials [37, 79-81].

Encapsulation is mainly divided into to two methods micro and macr-encapsulation respectively. In mechanism of micro-encapsulation, micro-capsules are directly embedded into fresh concrete matrix, when cracks appeared on the surface, these micro-capsules start disseminating into cracks. In the recent past, a wide range of new materials and methods for micro-encapsulation have been studied by many researcher. For better performances, many thermally stabled encapsuled-materials such as polyurea-formaldehyde and plyurea are used an agent for self-healing [26, 82-87]. The liberation of encapsulated material in matrix can cause unacceptable chemical changes in concrete like dis-assembly of capsule shell. The main issue with embedding other materials in concrete is the chances of reduction in pH of concrete which will lead to acidity and cause ingress of chloride and corrosion of steel reinforcement. To tackle with this problem, high pH materials have been proposed to embed in concrete for healing [88-91]. Different new improved methods have been proposed to employ for micro-encapsulation process. Micro-fluidics is relatively a new technique than previously commonly used techniques (chemical and physio-chemical). A detailed micro-encapsulation method is given in [92-94]. Whereas, macro-encapsultion is usualy done with the materials of size more than 1mm. Glass and polypropylene fibers were proposed to be used as crack repairing/healing materials. For proper crack-healing, the fibers in combination with cheap encapsulation materials were mixed together to get a proper solution before use. They found that this technique gave better results/output than the micro-capsules because this technique of crack-healing was able to all of the stored healing agent was able to show proper contribution in healing of crack [95-97]. Hollow glass fibers filled with ethyl-cyanoacylite glue and alkali-silica solutions were studied the results showed recovery in crack-healing [26, 98]. It was suggested that the incorporation of glass fibers have negative impact on durability of concrete because of possible alkali-silica-reactions (ASR). To avoid ASR, it was suggested to use ceramic capsules [33, 99-101].

Studying the self-healing concrete, one must assess the efficiency of healing approaches. The performance of self-healing concrete is evaluated in many ways by researchers, depending on the mechanism of healing of concrete, specific property of healing concrete, technique, availability of evaluation equipment, machine etc. some of the evaluation techniques are given many international renowned standards but some are created/discovered/invented by researchers by themselves and claimed that these methods or techniques gave best results as expected. In their detailed study, and research in field of self-healing concrete, a general classification of evaluating self-healing concrete on basis of the properties of healed concrete was proposed by [22]. They characterized the methods in three (03) major groups, namely (1) visualization and determination, (2) assessment of regained resistance and (3) regained mechanical properties. Sub-sections of the above three major groups are described below in brief.

In this section, mostly qualitative methods of evaluating healing are described. The qualitative methods show the mechanism that occur inside the self-healing concrete structures, its composition, crystal deposition, release of encapsulated healing agent and process of crack-filling.

For evaluation of cementitious materials, microscopic techniques are mostly used. With the help of microscopy, microstructure and structure of the specimens are observed. The chief test techniques in this category are; (1) petrographic inspections along with optical microscopy, (2) scanning electron microscopy (SEM) and (3) environmental SEM. In first case, a digital microscope is used to detect the crack surface, contours of crack surface, crystalline products and crack width size [38, 101-104]. SEM and ESEM are most commonly used techniques along with back-scattered electron imaging (BSEI). These methods give statistics about the crystallographic arrangement of the sample and describe the shape and size, morphology of re-hydrated products in cracks [6]. These test techniques have been used widely to study self-healing approaches in self-healing concrete. Numerous researchers have done experiments on engineered cementitious composites (ECC) to assess the effectiveness of the autogenous crack-healing mechanism through microscopy [70, 102, 103, 105, 106]. Moreover, the usage of SAPs to increase autogenous healing was checked by microscopic evaluation methods [106]. Besides, the influence of autogenous healing owing to continued crystallization succeeding from use of extensive additives, geo-materials and chemical agents were also assessed through optical microscopy and SEM [107, 108]. Also, petrographic investigations were carried out to investigate the influence of compressive forces on development of autogenous self-healing in hydrating concrete [22]. With regards to autonomous healing, autonomous healing mechanism was investigated by optical microscope in the concretes containing gelatin shelled-tung oil [25]. Microscopic analysis has also been a common means to examine the autonomous crack healing capability of bacteria-based concretes [3, 11, 50, 52, 104, 109-111]. Furthermore, microscopy examination technique has been commonly used in several researches to observe the capsule-based autonomous healing.

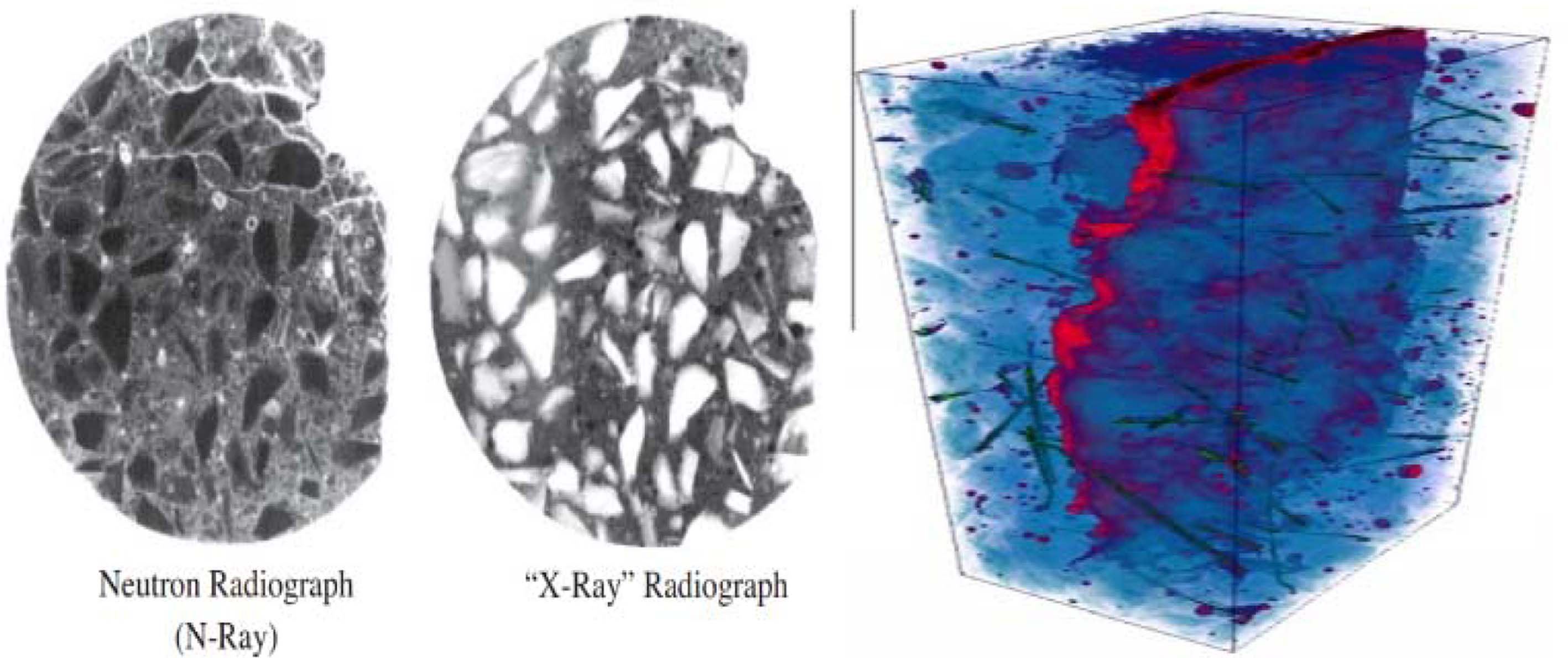

Similar to microscopic technique, imaging has also been used frequently to visualize the concrete structure before and after healing. Though, visualization of release of healing material from entrenched tubes/capsules and few other quantification analyses are likely to be seen from imaging. Key test methods for imaging comprise BSE Imaging, X-ray tomography/radiography, digital image correlation (DIC), neutron tomography/radiography. The BSE Imaging is commonly carried-out with SEM but in case of SEM only low atomic number elements can be visualized whereas, in case of BSEI, the elements having high atomic numbers can easily be visualized. The radiography is used in visualization because it gives two dimensional (2D) images of the structure of the sample as shown in Fig. 15. Whereas, the tomography gives the three dimensional (3D) images of structure.

The DIC is an optical technique which precisely detects changes in 2D and 3D images by tracing and image registration practices. Also DIC helps in close investigations of crack expansion and termination. DIC analysis was used to calculate the crack stoppage because of developed autogenous-healing by use of shrinkable polymers [24]. The deformations, displacements and optical flow were observed by thermography [112]. X-ray radiography was conducted to examine the autonomous healing in concrete which had encapsulated two-part epoxy with urea formaldehyde formalin (UFF) and two-part healing agent [99, 113]. Neutron radiography and tomography was employed to visualize and measure the capillary water up-take in healed cracks owing to capsule-based healing setup [114].

|

Fig. 15 Images of neutron radiograph, X-ray radiograph in 2D images [115] and 3D image tomography [17]. |

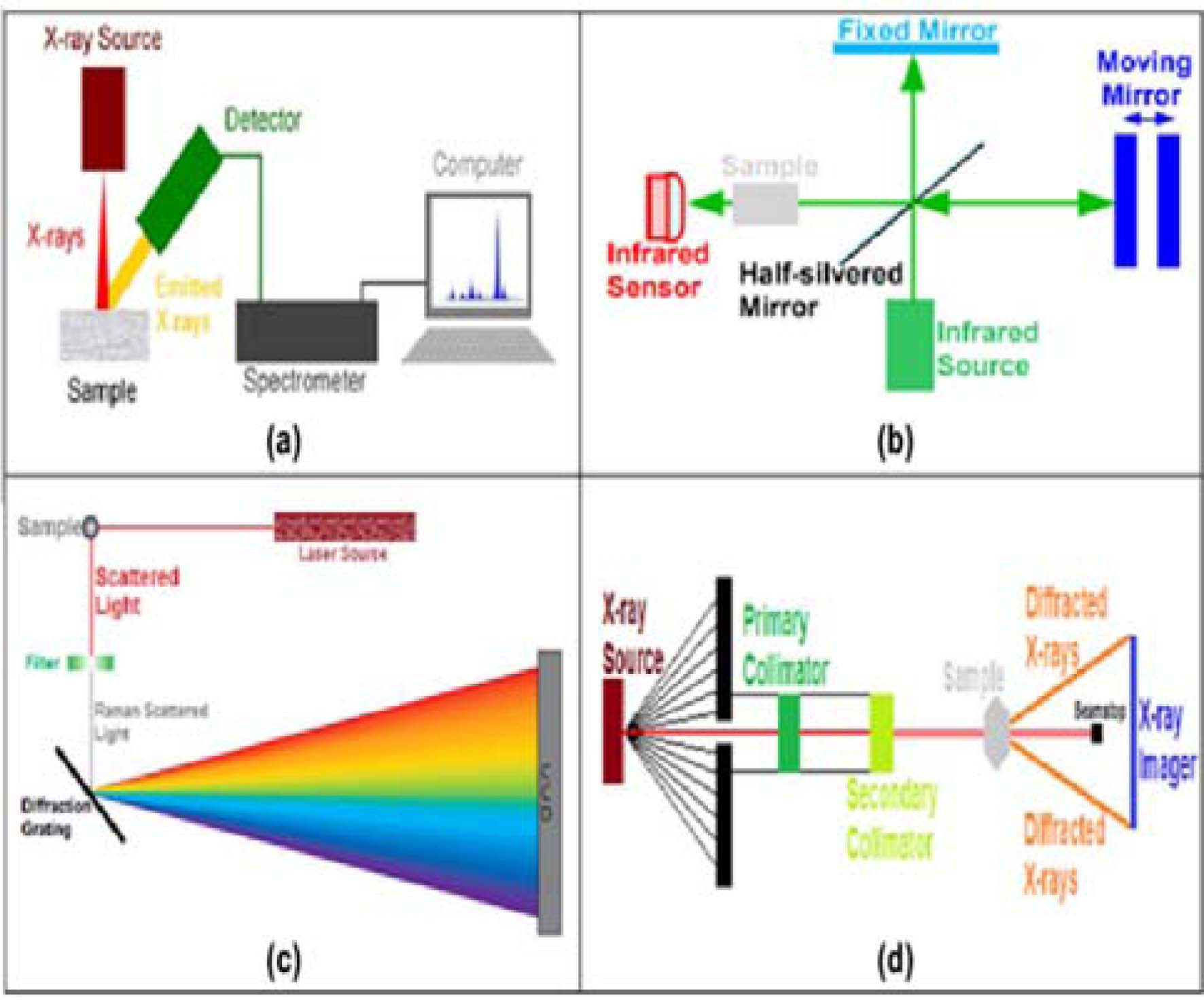

Crystalline materials, precipitated products and chemical composition in healed specimens were determined through spectroscopic investigations. In spectroscopic method, a beam of light is passed through sample which store/record the spectrum of transferred light. Molecular and atomic structure of the samples in respective peaks, position and shape are collected with the spectroscopy. Most commonly used spectroscopic measuring methods are X-ray spectroscopy (XRS), infrared spectroscopy (IS), Raman spectroscopy (RS) and X-ray diffraction (XRD) analysis. XRS deals with X-ray spectrum whereas, IS analysis feats light beams in the infrared area of the electromagnetic spectrum. Both of these methods assist in finding and resolving of precipitated products in a healed sample [104]. In addition, RS depends on scattering of mono-chromatic light, usually from a laser source which gives information on chemical composition of crystallization products [102]. Whereas, XRD analysis gives 3D images of the crystalline structure of a sample by determining the characteristics of X-ray beams diffracted because of the atomic structure of the samples. Like so, the composition of the re-hydrated product in self-healing region can be checked [108].

Existence of cracks in concrete can govern to discontinuity of matrix and as result in high risk against permeation of fluids in it. During healing process these cracks squeezes themselves to make concrete more efficient. For this reason, important group of techniques are working to self-heal the mechanism in concrete. Most important signs of the regained resistances of self-healing concretes are transport properties, resistivity and continuity.

Most common test methods in this group for measuring self-healing in concrete are water and air permeability, sorptivity, osmotic pressure and chloride diffusivity. Water permeability and air permeability are most commonly test techniques which are used in almost every self-healing test method [17, 115-117]. Sorptivity test method deals with capillary water suction [118]. Another transport characteristic in concrete is dealing with resistance against chloride ions. The degree of regained resistance against chloride diffusion is assessed as an indicator of the effectiveness of self-healing process. Osmotic pressure is dealt with the selective perviousness of concrete with against solutes, ions and water. Numerous researchers conducted water permeability, water pressure test [119-123] and transport of different chemicals [11, 124]. Permeability of concrete structures play a vital role in controlling the properties of concrete. The performance of concrete structures is also influenced by the permeability. The corrosion of steel reinforcement is directly related the water permeability of concrete. Therefore, it is necessary to stop the permeability of water in concrete to avoid corrosion and durability problems. Water permeability test (WPT) was conducted on concrete specimens. Different size of cracks was produced on cement pastes, mortars, normal and high strength concretes. The minimum and maximum crack sizes were 50 microns 350 micron respectively. During WPT, only the inflow was measured. It was observed that the crack size <100 microns didn’t show any permeability whereas the crack size >100 microns were affected with permeability [1].

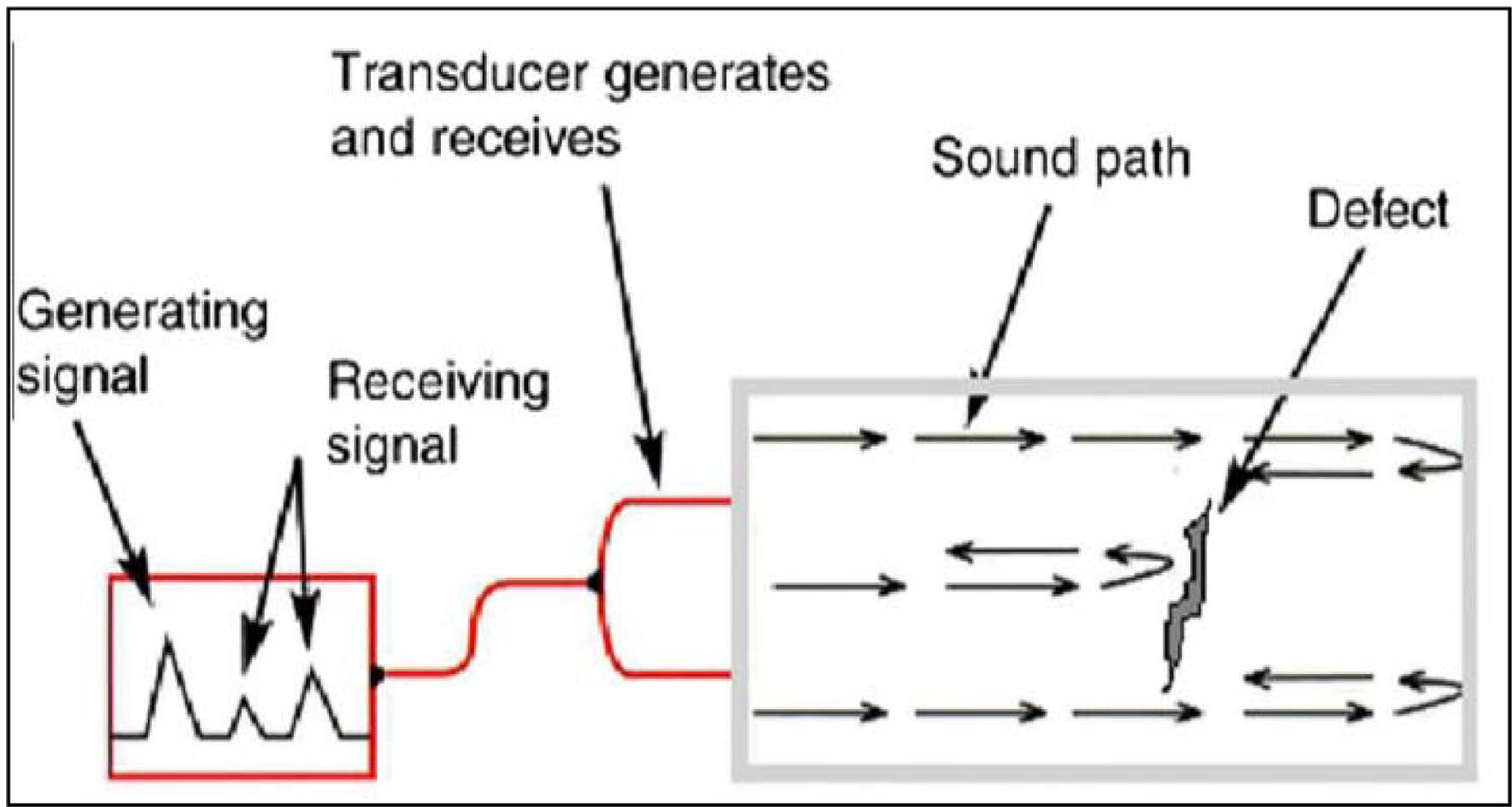

Resistivity is directly related with durability properties of concrete structures because it belongs to continuity of matrix. The most used tests in this category are ultrasonic measurements, corrosion resistance tests, frost/salt scaling. In case of ultrasonic testing, short ultrasonic waves are passed from the matrix to perceive internal defects and cutoffs. If there is no blockage or defect in concrete, the waves pass quickly as compared to defective concrete. There is one disadvantage of ultrasonic testing because in presence of moisture/water in concrete, it does not give true result results whereas, the detection during autogenous healing it is very necessary to notice the availability of water [125]. Corrosion testing is necessary to know the corrosion rate in steel. Because the reinforcement used in concrete is very susceptible to corrosion. So it resistance is necessary. Frost scaling states the exposure of concrete to freeze-thaw action. This phenomenon mostly occurs in case of roads and marine structures because the outer environment changes with seasons and these structures are facing more threat to this. Many researchers used ultrasonic testing technique to investigate autogenous healing effect in concretes containing polymers and pozzolans [37, 125, 126]. Also few researchers investigated corrosion transport in autogenous and autonomous concretes containing calcium nitrate fibers and sodium silicates. Frost scaling test was conducted by [97, 127, 128] on autogenous healed concretes.

The presence of cracks in concrete matrix significantly reduces the strength and stiffness of concrete. For this reason, the key approaches of self-healing concrete are to investigate the mechanical characteristics of concrete after its healing. The comparison of regained mechanical strength is necessary to evaluate the difference between strength regained and the strength before the appearance of crack. The most commonly used mechanical performance test techniques in self-healing concretes are 3-point and 4-point bending tests, tensile tests, horizontal deformation and impact loading tests. Two more methods are also used to check performance which are actually non-mechanical test that are acoustic emission (AE) and resonance frequency (R.F) analysis.

Bending tests are most popular test methods to create artificial cracks in a self-healing concrete specimens mechanically. The procedure of this type of testing is first create cracks and record the load. After that, allow the specimens to heal-cracks itself. After a designated period of time, the healed specimens are further loaded in same way as earlier/before healing. Now both the loading results will be compared and regain in mechanical strength will be identified. A number of researchers used bending tests to explore the improved autogenous healing in concrete through restriction of crack width [126, 129-131], adding of internal curing agents and application of compressive forces [22, 78, 132, 133]. Autogenous self-healing effect in high performance concrete was investigated by [133]. Another study used 4-point bending test for knowing healing efficiency of concrete containing encapsulated epoxy agent [134]. Also, several researchers examined the self-healing efficiency of autonomous healing concrete [127, 135-139]. Few researchers used compression testing for analyzing self-healing effect in concretes [40, 102, 137]. Capsule-based autonomous healing was investigated by [133] following compression test.

During horizontal deformation test, horizontal load with defined displacement is applied to the top of a column-shaped sample to generate artificial cracks. After the self-healing, the test was repeated again to assess the healing productivity. Commonly, a concrete slab specimen is used for impact loading test and the impact energy is examined upon drop of a heavy weight from a constant height. These two (2) mechanical test methods have been used to examine the capsule-based autonomous self-healing mechanism [134, 140]. In (AE) analysis, transient elastic waves are produced because of sudden stress in the material. Evolving micro-cracks in the matrix can release the energy in shape of stress waves which then can be recorded with sensors. Like so, some information will be gotten about the healing mechanism inside the specimen. Furthermore, regained internal energy can be assessed in the healed concrete. The autogenous self-healing in ECC was studied through AE analysis by [3]. Other researchers [11, 141] investigated the autogenous healing effect in an UHPC using AE analysis. RF analysis can be used to measure flexural, longitudinal and torsional resonant frequencies in specimens. RF analysis permits assessment of recovered stiffness, evaluation of the degree of self-healing as well as the quantification of the extent of damage and retrieval. More than a few authors studied the regained mechanical characteristics in healed concrete owing to autogenous self-healing influence using RF analysis [142, 143].

It was observed that the mechanical strength was regained in healed concrete after healing of crack. The strength was much lower compared to the virgin concrete. In general, it can be noted that small healed-cracks have high strength as compared to larger one but in this study it was not accordingly as shown in Fig. 20 [6].

Finally, it was established from the results of specimens from this research that the CaCO3 precipitation will only contribute a little part in strength gain in case of autogenous crack-healing [6]. It can be seen in Fig. 14 that there was a strength gain up to 50-60% in the specimens in which polyurethane was used as a carrier as compared to reference sample. In the specimens containing silica gel, strength gain was high as compared to reference sample but strength was low as compared to samples containing polyurethane. The difference in both specimens containing carrier was due to the type of carrier/material used. Because the polyurethane is an organic material that has more strength as silica gel.

Fig. 16 Fig. 17 Fig. 18 Fig. 19 Fig. 21

|

Fig. 16 Spectroscopy methods (a) XRS, (b) IS, (c) RS and (d) XRD analysis [17]. |

|

Fig. 17 Ultrasonic testing technique of concrete samples [17]. |

|

Fig. 18 Bending test on self-healing concrete (a) before healing and (b) after healing [115]. |

|

Fig. 19 Horizontal deformation test set-up [136]. |

|

Fig. 20 Strength gain after healing of crack [6]. |

|

Fig. 21 Strength gain after healing of crack [11]. |

The concrete itself does not provide much healing to heal its cracks. It only heals very small cracks by itself by the mechanism of autogenous healing. The previous studies show that the concrete with autogenous healing, heals only very small crack widths but the size of crack widths are varying. Because some studies show that the crack widths of size 0.01 mm to 0.1 mm can be healed easily in presence of moisture. Whereas, some studies demonstrate the crack widths of 0.2 mm can also be healed with presence of water. If there is no moisture or water it will be very difficult to access autogenous healing. So in this case, someone cannot depend on the autogenous healing. For this reason, concrete is engineered to trigger autogenous self-healing. The triggered autogenous healing is further reliant on its constituents specifically unreacted binding particles. Similar to previous case, there will be no any difference in size of crack-healing. In this case, the addition of fibers in concrete can help in minimizing the earlier appeared cracks, which will the easily be healed with autogenous healing mechanism because the crack sizes will be very small than that of without fibers. The addition of mineral admixtures plays a promising role in enhancing self-healing of concrete because it promotes C-S-H gel in continued hydration whereas, some studies show adverse effect of mineral admixtures in concrete because precipitation of CaCO3 is stopped during dry-wet cycles. This influence in concrete depends on the self-healing conditions and the mix design which is being used for making concrete. Also the healing mechanism in presence of mineral admixtures like slag and fly ash is very slow takes long time so heal cracks, to mitigate this problem, alkaline activators are suggested be used while making concrete. These activators help in early hydration reaction in concrete and in result Self-healing of cracks occur earlier. The problem with using activators is the cost. Because the cost of concrete increases while using alkaline activators. Also the addition of fibers increases the cost of concrete therefore it is suggested to use natural fibers to reduce total cost. SAPs and porous light weight aggregates LWA can be used for self-healing mechanism in concrete. Because they contain water inside it when a crack is appeared in concrete, the internal water release to crack mouth in form of moisture which then help in reaction of unhydrated cement and with time that crack heals. So the use of SAPs and LWA are encouraged to apply. Also the combination of these both or different SAPS are suggested to be used. But the mechanical and durability problems should be kept in mind because no one can compromise on these properties. One of the problem with autogenous healing material is that they work only for 1-3 years from casting date. It is recommended to use liquid phase change materials (PCMs) for self-healing concrete. These PCMs should only work when cracks appear on surface. If there is no crack these material should stop their work and remain in solid form.

On the other hand, the autonomous self-healing concretes are designed to heal the cracks of sizes up to 1mm. the materials for autonomous healing include bacteria-based systems, micro-encapsulation with minerals and polymers, macro-encapsulation minerals and polymers. Encapsulation with shell materials was investigated in literature, it was found that the concrete was very hard and stiff, the bonding between cementious matrix was improved, whereas, the mechanical strength was reduced. With the encapsulation, cracks up to 1000µm were sealed. It was recommended to use a dosage of 0.5 5 to 10% of cement to balance the mechanical strength with other properties. Similar trend (short-life span) was noticed in autonomous healing concrete as it was noticed in autogenous healing system. To overcome this problem enormous researchers used mineral cargos or bacterial spores. They used these systems to improve the life span of healing agents in concrete so as there should be no further repair problem in concrete in future but they were still unable to get that, somehow they got good results in vascular network system of autonomous healing in laboratory or small levels. However, still there is a challenge to use this system in large concrete works. The bacteria-intervened systems have also their limitations as well. Denitrification and aerobic oxidation systems have negative impact on CaCO3 precipitation yields as compared to ureolytic systems. However, in view of environmental considerations, urea hydrolysis has demerits because it produces ammonia as byproduct. Also the aerobic and ureolytic self-healing mechanism has disadvantage of creating corrosion in steel during healing period. Both the bacterial self-healing and stimulated autogenous healing work on similar mechanism in which CaCO3 precipitation occurs but it is very hard for them to get the lost strength which the concrete had before appearing crack. In addition, CaCO3 is soluble in acidic environment, and will not give good results in the conditions where pH of the system is low. To devastate these hitches, a system with more power to resist acidic sources and a strong material with low modulus elasticity will be required.

In addition, the forthcoming work should focus on the self-healing agents/materials which to be used in concrete (1) should be cheap (2) should be available in local markets, (3) should be durable (4) should have no adverse impact on strength, (5) should have long life-span (6) should resist unwanted sources which are harmful for concrete.

In today’s modern world, in any field, everyone is trying to get good output from the thing they have. Like, doctors are trying to give that medicine to patients by which patient becomes healthy as early as possible, similarly teachers or professor are trying to give lectures in a way by which students should learn easily. Lawyers are presenting solid reasons or proofs by which they are trying to win the cases. Engineers are trying to quick application of the materials or ideas they have. In the same way, a material engineer is trying to make materials that can be used frequently and have many advantages. Concrete is also one of the materials that have many applications therefore it the second most consumable material in the world after water. Today more durable and high strength and high performance concretes are made which have the life-span more than 100 years. In this modern era of the concrete technology, self-healing concrete has also received response from clients and the engineers. The major part of paper includes the introduction part, reviewed literature, self-healing approaches/mechanism, the methods and materials used for self-healing concrete and assessment techniques of crack-healing. This paper reviews the research work of numerous researchers in this field. Literature is reviewed from almost 150 sources which include reach articles, conference papers, written books, review papers and many more. The aim of this paper is to enlighten the work of numerous researchers who worked and studied about self-healing concrete. It is observed from the reviewed literature that the self-healing of concrete is much necessary for today’s world. Many advantages were observed during this study which are listed below;

saving money on further material for repair; as we know, conventional concrete needs more money on buying further new materials for repair, whereas, self-healing concretes do not need for this purpose. (2) minimizes further usage of natural resources/materials; no further extraction of natural resources for repair will be needed, (3) saves further money on man-power; because further repair will require man-power to repair the concrete structure which in result will increase the cost, (4) saves time; as we know time is precious, that saved time we can use somewhere else, (5) saves energy; mechanical power for repair will be reduced, (6) minimizes the throwing of waste from construction industry; because self-healed concrete takes more time to demolish, in this way a delay in throwing waste will be notified, (7) high performance; self-healing concrete shows high performance as compared to conventional concrete. Some demerits of self-healing concrete were also observed during this study. Such as;

increased initial cost; initial cost will be increased because self-healing concrete needs extra materials, (2) proper care; during mixing of concrete a proper care will be needed to put proper dosage/amount of healing agents in concrete, (3) short life span of healing agents; healing agents does not live long, which again will need repair in near future.

Furthermore, it was witnessed in the previous papers that the most of researchers performed various test methods to verify healing mechanism in concrete. Test methods, such as (1) microscopy, which includes, optical microscopic, SEM, ESEM, BSEI, (2) imaging, which includes X-ray tomography/radiography, DIC, neutron tomography and radiography, (3) spectroscopic, which includes XRS, IR, Raman spectroscopy, XRD analysis, (4) transport properties, which include water permeability, air permeability, sorptivity, chloride diffusivity and osmotic pressure, resistance permeability, ultrasonic measurements, corrosion, frost scaling and (5) strength performance, which includes 3-point and 4-point bending tests, tensile tests, compressive tests, horizontal deformation and impact loading tests, acoustic emission and resonance frequency test analysis were used for that purpose. Finally, it was concluded that the most of these techniques were beneficial for assessing crack-healing mechanism in self-healing concrete.

In addition, it is recommended to make concrete in real level application because none of the researchers used self-healing concrete in real application environment. Also for this reason, the evaluation techniques which were used in laboratory level specimens, can further be changed/enhanced.

The authors would like to acknowledge this work to the Ph.D. and graduate students of Concrete Engineering Laboratory, Civil and Environmental Engineering Department, Hanyang University, Seoul, Republic of Korea for their precious time to help in writing, drafting and formatting this paper.

The authors announce no conflict of interest.

- 1. C.-M. Aldea, S.P. Shah and A. Karr, Mater. Struct. 32 (1999) 370-376.

-

- 2. L. Basheer, J. Kropp and D.J. Cleland, Constr. Build. Mater. 15 (2001) 93-103.

-

- 3. M. Sahmaran, M. Li and V.C. Li, ACI Mater. J. 104 (2007) 604.

- 4. M.D. Hager, P. Greil, C. Leyens, S. van der Zwaag and U.S. Schubert, Adv. Mater. 22 (2010) 5424-5430.

-

- 5. H.G. Kim, A. Qudoos and J.-S. Ryou, Constr. Build. Mater. 188 (2018) 569-582.

-

- 6. K. Van Tittelboom, E. Gruyaert, H. Rahier and N. De Belie, Constr. Build. Mater. 37 (2012) 349-359.

-

- 7. C. Stuckrath, R. Serpell, L.M. Valenzuela and M. Lopez, Cem. Concr. Compos. 50 (2014) 10-15.

-

- 8. M. De Rooij, K. Van Tittelboom, N. De Belie and E. Schlangen, in “Self-healing phenomena in cement-Based materials”, (Dordrecht Spring Press, 2013) p.9.

-

- 9. S.K. Ghosh, in “Self-healing materials: fundamentals, design strategies, and applications” (WILEY-VCH Press, 2009) p.1-2.

-

- 10. K. Van Breugel, in Proceedings of the first international conference on self-healing materials, April 2007, edited by Alexander J M Schmets; Sybrand van der Zwaag (Dordrecht Springer Press, 2007) p. 1-9.

- 11. J. Wang, K. Van Tittelboom, N. De Belie and W. Verstraete, Constr. Build. Mater. 26 (2012) 532-540.

-

- 12. J. Wang, D. Snoeck, S. Van Vlierberghe, W. Verstraete and N. De Belie, Constr. Build. Mater. 68 (2014) 110-119.

-

- 13. M. Luo, C.-X. Qian and R.-Y. Li, Constr. Build. Mater. 87 (2015) 1-7.

- 14. J. Parks, M. Edwards, P. Vikesland and A. Dudi, J. Mater. Civ. Eng. 22 (2010) 515-524.

-

- 15. H. Huang, G. Ye and D. Damidot, Cem. Concr. Res. 60 (2014) 68-82.

-

- 16. J. Wang, H. Soens, W. Verstraete and N. De Belie, Cem. Concr. Res. 56 (2014) 139-152.

-

- 17. W. Tang, O. Kardani and H. Cui, Constr. Build. Mater. 81 (2015) 233-247.

-

- 18. A. Talaiekhozan, A. Keyvanfar, A. Shafaghat, R. Andalib, M.A. Majid, M.A. Fulazzaky, R.M. Zin, C.T. Lee, M.W. Hussin and N. Hamzah, JETT 2 (2014) 1-11.

- 19. A. Neville, Concr. Int. 24 (2002) 76-82.

- 20. C. Edvardsen, Mater. J. 96 (1999) 448-454.

- 21. C.M. Aldea, W.J. Song, J.S. Popovics and S.P. Shah, J. Mater. Civ. Eng. 12 (2000) 92-96.

-

- 22. N. Ter Heide, and E. Schlangen, in Proceedings of 1st International Conference on Self Healing Materials, April 2007, edited by A.J.M. Schmets, and S. van der Zwaag (Dordrecht Springer Press, 2007) p. 18-20.

- 23. Y. Yang, E.-H. Yang, and V.C. Li, Cem. Concr. Res. 41 (2011) 176-183.

-

- 24. M. Wu, B. Johannesson, and M. Geiker, Constr. Build. Mater. 28 (2012) 571-583.

-

- 25. E. Cailleux, and V. Pollet, in Proceedings of the 2nd International Conference on Self-Healing Materials, June 2009, edited by S.N. (Dordrecht Springer Press, 2009) p.5-8.

- 26. V.C. Li, Y.M. Lim and Y.W. Chan, Composites, Part B 29 (1998) 819-827.

-

- 27. C. Joseph, A.D. Jefferson, B. Isaacs, R.J. Lark and D.R. Gardner, Mag. Concr. Res. 62 (2010) 831-843.

-

- 28. S.M. Al-Thawadi, J. Adv. Sci. Eng. Res. 1 (2011) 98-114.

- 29. N. Chahal, A. Rajor and R. Siddique, Afr. J. Biotechnol. 10 (2011) 8359-8372.

-

- 30. S. Zwaag, in ‘Self Healing Materials: An Alternative Approach to 20 Centuries of Materials Science” (Dordrecht Springer Press, 2007) p. 23-168.

-

- 31. P. Ghosh, S. Mandal, S. Pal, G. Bandyopadhyaya and B. Chattopadhyay, Indian J. Exp. Biol. 44 (2006) 336-339.

- 32. K.S. Toohey, N.R. Sottos, J.A. Lewis, J.S. Moore and S.R. White, Nat. Mater. 6 (2007) 581.

-

- 33. K. Van Tittelboom and N. De Belie, Mater. 6 (2013) 2182-2217.

-

- 34. W. Khaliq and M. B. Ehsan, Constr. Build. Mater. 102 (2016) 349-357.

-

- 35. W. De Muynck, D. Debrouwer, N. De Belie and W. Verstraete, Cem. Concr. Res. 38 (2008) 1005-1014.

-

- 36. J. Qiu, H.S. Tan and E.-H. Yang, Cem. Concr. Compos. 73 (2016) 203-212.

-

- 37. A.E.M. Abd_Elmoaty, Alexandria Eng. J. 50 (2011) 171-178.

-

- 38. S. Sangadji, V. Wiktor, H. Jonkers and H. Schlangen, in Proceedings of the 4th International Conference on Self-Healing Materials, Ghent, Belgium, June 2013, edited by N De Belie (Magnel Laboratory for Concrete Research Press) p.118-122.

- 39. E. Schlangen and S. Sangadji, Procedia Eng. 54 (2013) 39-57.

-

- 40. T. Nishiwaki, S. Kwon, D. Homma, M. Yamada and H. Mihashi, Mater. 7 (2014) 2141-2154.

-

- 41. A. Hosoda, S. Komatsu, T. Ahn, T. Kishi, S. Ikeno and K. Kobayashi, in Proceeding of 2nd International Conference on Concrete Repair, Rehabilitation and Retrofitting, November 2008, edited by M.G. Alexander, H.D. Beushausen, F. Dehn and P. Moyo (CNC Press, 2009) p.121-124.

- 42. H. Siad, A. Alyousif, O.K. Keskin, S.B. Keskin, M. Lachemi, M. Sahmaran and K.M.A. Hossain, Constr. Build. Mater. 99 (2015) 1-10.

-

- 43. B. Pang, Z. Zhou, P. Hou, P. Du, L. Zhang and H. Xu, Constr. Build. Mater. 107 (2016) 191-202.

-

- 44. B. Dong, N. Han, M. Zhang, X. Wang, H. Cui and F. Xing, J. Earthq. Tsunami 7 (2013) 1350014.

-

- 45. R. Berner, Geochim. Cosmochim. Acta 39 (1975) 489-504.

-

- 46. S. Castanier, G. Le Metayer-Levrel and J.P. Perthuisot, Micro. Sediments (2000) 32-39.

-

- 47. R. Riding, Sedimentology 47 (2000) 179-214.

-

- 48. S. Douglas and T.J. Beveridge, FEMS Microbiol. Ecol. 26 (1998) 79-88.

-

- 49. F. Ferris, W. Fyfe and T. Beveridge, Geology 16 (1988) 149-152.

-

- 50. H.M. Jonkers, A. Thijssen, G. Muyzer, O. Copuroglu and E. Schlangen, Ecol. Eng. 36 (2010) 230-235.

-

- 51. A. Moldovan, S. Patachia, C. Vasile, R. Darie, E. Manaila and M. Tierean, J. Biobased Mater. Bioenergy 7 (2013) 58-79.

-

- 52. K. Van Tittelboom, N. De Belie, W. De Muynck and W. Verstraete, Cem. Concr. Res. 40 (2010) 157-166.

-

- 53. P.Y. Chen, J. McKittrick and M. A. Meyers, Prog. Mater. Sci. 57 (2012) 1492-1704.

-

- 54. K. Liu, Y. Tian and L. Jiang, Prog. Mater. Sci. 58 (2013) 503-564.

-

- 55. S. Bauer, P. Schmuki, K. von der Mark and J. Park, Prog. Mater. Sci. 58 (2013) 261-326.

-

- 56. H.V. Knorre and W.E.Krumbein, Microb. Sediments (2000) 25-31.

-

- 57. S. Sanchez-Moral, J.C. Cañaveras, L. Laiz, C. Sáiz-Jiménez, J. Bedoya and L. Luque, Geomicrobiol. J. 20 (2003) 491-500.

-

- 58. V.C. Li and E.H. Yang, Self-Healing Mater. (2007) 161-193.

-

- 59. S.K. Ramachandran, V. Ramakrishnan and S.S. Bang, ACI Mater. J. 98 (2001) 3-9.

- 60. C.C. Hung, Y.F. Su and H.H. Hung, Cem. Concr. Compos. 80 (2017) 200-209.

-

- 61. E. Gruyaert, K.V. Tittelboom, H. Rahier and N.D. Belie, J. Mater. Civ. Eng. 27 (2014) 04014208.

-

- 62. K. Kabiri, H. Omidian, S. Hashemi and M. Zohuriaan-Mehr, Eur. Polym. J. 39, (2003) 1341-1348.

-

- 63. Y. Yao, Y. Zhu and Y. Yang, Constr. Build. Mater. 28 (2012) 139-145.

-

- 64. H. Lee, H. Wong and N. Buenfeld, Adv. Appl. Ceram. 109 (2010) 296-302.

-

- 65. A. Mignon, D. Snoeck, P. Dubruel, S. Van Vlierberghe and N. De Belie, Mater. 10 (2017) 237.

-

- 66. D.P. Bentz and W.J. Weiss, in “Internal curing: a 2010 state-of-the-art review” (National Institute of Standards and Technology Press, 2011) p.1-64.

-

- 67. S.-I. Igarashi and A. Watanabe, In International RILEM conference on volume changes of hardening concrete: testing and mitigation, August 2006, edited by O.M. Jensen, P. Lura, and K. Kovler (RILEM Publications, 2006) p.77-86.

-

- 68. J. Justs, M. Wyrzykowski, D. Bajare and P. Lura, Cem. Concr. Res. 76 (2015) 82-90.

-

- 69. D. Snoeck, D. Schaubroeck, P. Dubruel and N. De Belie, Constr. Build. Mater. 72 (2014) 148-157.

-

- 70. D. Snoeck, S. Steuperaert, K. Van Tittelboom, P. Dubruel and N. De Belie, Cem. Concr. Res. 42 (2012) 1113-1121.

-

- 71. J. Pelto, M. Leivo, E. Gruyaert, B. Debbaut, D. Snoeck and N. De Belie, Smart Mater. Struct. 26 (2017) 105043.

-

- 72. E. Gruyaert, B. Debbaut, D. Snoeck, P. Díaz, A. Arizo, E. Tziviloglou, E. Schlangen and N. De Belie, Smart Mater. Struct. 25 (2016) 084007.

-

- 73. D. Snoeck and N. De Belie, biosyst. Eng. 111 (2012) 325-335.

-

- 74. D. Snoeck and N. De Belie, Constr. Build. Mater. 95 (2015) 774-787.

-

- 75. H. Lee, H. Wong and N. Buenfeld, Cem. Concr. Res. 79 (2016) 194-208.

-

- 76. D. Snoeck, in “Self healing concrete by the combination of microfibres and reactive substances” (Ghent University Press, 2011), p.1-64.

- 77. D. Snoeck, L. Velasco, A. Mignon, S. Van Vlierberghe, P. Dubruel, P. Lodewyckx and N. De Belie, Cem. Concr. Res. 77 (2015) 26-35.

-

- 78. J.S. Kim, E. Schlangen, in 2nd International Symposium on Service Life Design for Infrastructures, October 2010, edited by K. van Breugel, G. Ye and Y. Yuan (RILEM Publications, 2010) p. 849-858.

- 79. L. Czarnecki and P. Łukowski, Cem.-Wapno-Beton 5 (2010) 243-258.

- 80. N.Z. Muhammad, A. Shafaghat, A. Keyvanfar, M.Z A. Majid, S. Ghoshal, S.E.M. Yasouj, A.A. Ganiyu, M.S. Kouchaksaraei, H. Kamyab and M.M. Taheri, Constr. Build. Mater. 112 (2016) 1123-1132.

-

- 81. P. Łukowski and G. Adamczewski, Bull. Pol. Acad. Sci.: Tech. Sci. 61 (2013) 195-200.

-

- 82. S.R. White, N. Sottos, P. Geubelle, J. Moore, M.R. Kessler, S. Sriram, E. Brown and S. Viswanathan, Nature 409 (2001) 794.

-

- 83. E. Mostavi, S. Asadi, M.M. Hassan and M. Alansari, J. Mater. Civ. Eng. 27 (2015) 04015035.

-

- 84. Z. Yang, J. Hollar, X. He and X. Shi, Cem. Concr. Compos. 33 (2011) 506-512.

-

- 85. X. Wang, F. Xing, M. Zhang, N. Han and Z. Qian, Mater. 6 (2013) 4064-4081.

-

- 86. L. Lv, E. Schlangen, Z. Yang and F. Xing, Mater. 9 (2016) 1025.

-

- 87. L. Lv, Z. Yang, G. Chen, G. Zhu, N. Han, E. Schlangen and F. Xing, Constr. Build. Mater. 105 (2016) 487-495.

-

- 88. B. Dong, Y. Wang, W. Ding, S. Li, N. Han, F. Xing and Y. Lu, Constr. Build. Mater. 56 (2014) 1-6.

-

- 89. B. Dong, Y. Wang, G. Fang, N. Han, F. Xing and Y. Lu, Cem. Concr. Compos. 56 (2015) 46-50.

-

- 90. B. Dong, W. Ding, S. Qin, N. Han, G. Fang, Y. Liu, F. Xing and S. Hong, Cem. Concr. Compos. 85 (2018) 83-91.

-

- 91. B. Dong, W. Ding, S. Qin, G. Fang, Y. Liu, P. Dong, S. Han, F. Xing and S. Hong, Constr. Build. Mater. 168 (2018) 11-20.

-

- 92. Y. Hennequin, N. Pannacci, C.P. de Torres, G. Tetradis-Meris, S. Chapuliot, E. Bouchaud and P. Tabeling, Langmuir 25 (2009) 7857-7861.

-

- 93. N. Vilanova, C. Rodríguez-Abreu, A. Fernández-Nieves and C. Solans, ACS Appl. Mater. Interfaces 5 (2013) 5247-5252.

-

- 94. N. De Belie, E. Gruyaert, A. Al□Tabbaa, P. Antonaci, C. Baera, D. Bajare, A. Darquennes, R. Davies, L. Ferrara and T. Jefferson, Adv. Mater. Interfaces (2018) 1800074.

-

- 95. C. Dry, J. Intell. Mater. Syst. Struct. 4 (1993) 420-425.

-

- 96. C. Dry, Smart Mater. Struct. 3 (1994) 118.

-

- 97. C. Dry and W. McMillan, Smart Mater. Struct. 5 (1996) 297.

-

- 98. C. Joseph, A. Jefferson and M. Cantoni, in Proceedings of the First International Conference on Self Healing Materials, Aprill 2007, edited by S. van der Zwaag (Dordrecht Springer, 2007) p.1-8.

- 99. K. Van Tittelboom, N. De Belie, D. Van Loo and P. Jacobs, Cem. Concr. Compos. 33 (2011) 497-505.

-

- 100. B. Hilloulin, K. Van Tittelboom, E. Gruyaert, N. De Belie and A. Loukili, Cem. Concr. Compos. 55 (2015) 298-307.

-

- 101. E. Gruyaert, K. Van Tittelboom, J. Sucaet, J. Anrijs, S. Van Vlierberghe, P. Dubruel, B. De Geest, J.P. Remon and N. De Belie, Mater. Constr. (madrid, Spain) 66 (2016) 092.

-

- 102. D. Homma, H. Mihashi and T. Nishiwaki, J. Adv. Concr. Technol. 7 (2009) 217-228.

-

- 103. T. Nishiwaki, M. Koda, M. Yamada, H. Mihashi and T. Kikuta, J. Adv. Concr. Technol. 10 (2012) 195-206.

-

- 104. V. Wiktor and H.M. Jonkers, Cem. Concr. Compos. 33 (2011) 763-770.

-

- 105. V.C. Li, J. Adv. Concr. Technol. 1 (2003) 215-230.

-

- 106. V.C. Li, S. Wang and C. Wu, ACI Mater. J. 98 (2001) 483-492.

- 107. K. Sisomphon, O. Copuroglu and A. Fraaij, Heron 56 [1/2] (2011) 13-32.

- 108. T.H. Ahn and T. Kishi, J. Adv. Concr. Technol. 8 (2010) 171-186.

-

- 109. J. Wang, N. De Belie and W. Verstraete, J. Ind. Microbiol. Biotechnol. 39 (2012) 567-577.

-

- 110. H.M. Jonkers, Heron 56 (1/2) (2011) p.19-20.

- 111. B. Van Belleghem, S. Kessler, P. Van den Heede, K. Van Tittelboom and N. De Belie, Cem. Concr. Res. 113 (2018) 130-139.

-

- 112. V.M. Malhotra and N.J. Carino, “Nondestructive Testing of Concrete Second Edition” (CRC Press, 2003) p.15.

- 113. H. Mihashi, Y. Kaneko, T. Nishiwaki and K. Otsuka, JCI Transactions 22 (2001) 441-450.

- 114. K. Van Tittelboom, D. Snoeck, P. Vontobel, F.H. Wittmann and N. De Belie, Mater. Struct. 46 (2013) 105-121.

-

- 115. G. Li, X. Huang, J. Lin, X. Jiang and X. Zhang, Constr. Build. Mater. 200 (2019) 36-45.

-

- 116. W.S. Najjar, H.C. Aderhold and K.C. Hover, Cem., Concr., Aggregates 8 (1986) 103-109.

-

- 117. C. ASTM, “1996 Annual Book of Astm Standards: Section 4”, (Astm Intl Press, 1996) p.56-62.

- 118. C. ASTM, “1585-04: Standard test method for measurement of rate of absorption of water by hydraulic-cement concretes”, ASTM International, USA (2004).

- 119. M. Song, S. Jeon, and Y. Song, in Proceedings of 3rd International Conference on Self Healing Materials, June 2011, edited by Ian Bond (Dordrecht Springer, 2011) p. 27-29.

- 120. H.W. Reinhardt and M. Jooss, Cem. Concr. Res. 33 (2003) 981-985.

-

- 121. M. Şahmaran and V.C. Li, Cem. Concr. Res. 39 (2009) 1033-1043.

-

- 122. H. Mihashi and T. Nishiwaki, J. Adv. Concr. Technol. 10 (2012) 170-184.

-

- 123. Nanayakkara, A. N. U. R. A., in Proceedings of Conference on New Technologies for Urban safety of Mega cities in Asia, October 2003, Vol. 3031.

- 124. H. M. Jonkers, in “Self healing materials” (Springer, 2007) p. 195-204.

-

- 125. T. Watanabe, Y. Fujiwara, C. Hashimoto and K. Ishimaru, Int. J. Mod. 25 (2011) 4307-4310.

-

- 126. M. Kunieda, K. Shimizu, T. Eguchi, N. Ueda and H. Nakamura, JSCE. Ser. E2 (Materials and Concrete Structures) 67 (2011) 508-521.

-

- 127. M. M. Pelletier, R. Brown, A. Shukla and A. Bose, Cem. Concr. Res, (2011).

- 128. K. Sisomphon, O. Çopuroğlu and A. Fraaij, Constr. Build. Mater. 25 (2011) 823-828.

-

- 129. Y. Sakai, Y. Kitagawa, T. Fukuta and M. Iiba, in Proceedings of the Smart Structures and Materials 2003 : Smart Systems and nondesturctive Evaluation for Civil ingrastructures, March 2003, edited by Shih-Chi Liu (SPIE Press, 2003) Vol. 5057, p.178-187.

-

- 130. S. Qian, J. Zhou, M. De Rooij, E. Schlangen, G. Ye and K. Van Breugel, Cem. Concr. Compos. 31 (2009) 613-621.

-

- 131. S. Qian, J. Zhou, H. Liu, M.R. De Rooij, E. Schlangen, W.F. Gard, and J.W. van de Kuilen, in Proceedings of 2nd International Conference on Self Healing Materials, June 2009, edited by s.n. (Dordrecht Springer Press, 2009) p.1-4.

- 132. D. Snoeck, K. Van Tittelboom, S. Steuperaert, P. Dubruel and N. De Belie, J. Intell. Mater. Syst. Struct. 25 (2014) 13-24.

-

- 133. S. Granger, A. Loukili, G. Pijaudier-Cabot and G. Chanvillard, Cem. Concr. Res. 37 (2007) 519-527.

-

- 134. THAO, T. D. P., in “Quasi-Brittle Self-Healing Materials: Numerical Modelling and Applications in Civil Engineering”, (National University of Singapore, 2011)

- 135. T. D. P. Thao, T. J. S. Johnson, Q. S. Tong and P. S. Dai, IES Journal Part A: Civil & Structural Enfineering 2 (2009) 116-125.

-

- 136. H. Huang, G. Ye, C. Leung, & K.T. Wan, in International RILEM conference on advances in construction materials through science and engineering, RILEM Publications SARL, September 2011, edited by Haoliang Huang and Guang Ye (RILEM Publications SARL 2011) p. 530-536.

- 137. Xing, Z. Ni, N.X. Han, B.Q. Dong, X.X. Du, Z. Huang & M. Zhang, in Proceedings of the International Conference on Durability of Concrete Structures, November 2008, edited by Yuxi ZHAO (Zhejiang University Press, 2008) Vol. 2627.

- 138. Z. Yang, J. Hollar, X. He and X. Shi, Transp. Res. Rec. 2142 (2010) 9-17.

-

- 139. Katsuhata, Y. Ohama, and K. Demura, in Proceedings of 10th International Congress on Polymers in Concrete, May 2001, edited by L. Sierra (ICRI Press, 2001) p. 23-25.

- 140. C.M. Dry, in Proceedings of Smart Structures and Materials 1997: Smart Systems for Bridges, Structures, and Highways, International Society for Optics and Photonics, May 1997, edited by Norris Stubbs ( SPIE Press, 1997) p.44-51.

- 141. S. Granger, G. P. Cabot, A. Loukili, D. Marlot and J.-C. Lenain, Cem. Concr. Res. 39 (2009) 296-302.

-

- 142. Y. Yang, M. D. Lepech, E.-H. Yang and V. C. Li, Cem. Concr. Res. 39 (2009) 382-390.

-

- 143. S. Jacobsen and E. J. Sellevold, Cem. Concr. Res. 26 (1996) 55-62.

-

This Article

This Article

-

2019; 20(S1): 1-18

Published on Jul 20, 2019

- Received on Dec 9, 2018

- Revised on Jan 21, 2019

- Accepted on Jan 21, 2019

Services

Services

- Abstract

introduction

literature review

self-healing approaches/mechanism

materials and methods

conclusions

- Acknowledgements

- Conflict of Interest

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jae Suk Ryou

-